Top Recycling Stories of 2015

As PT’s Editorial Director Jim Callari wrote earlier this year: recycling is here to stay.

As PT’s Editorial Director Jim Callari wrote earlier this year: recycling is here to stay. In fact, March’s NPE2015 show in Orlando featured more news in recycling than any previous NPE. More and more OEMs and brand owners are demanding that plastics processors deliver them products containing recycled materials. This has driven innovations in equipment technology that aim to make recovery more efficient than ever. Here are some of the highlights of the top recycling stories for 2015:

- Starlinger (Starlinger Sahm in the U.S.) unveiled at NPE its recoSTAR dynamic recycling line, which features highly automated operation and continuous process adjustments. This allows increased uptime and productivity while also reducing overall energy consumption by up to 10%. The recycling line starts up and shuts down automatically; and when the material feeding is stopped, the Smart feeder switches into standby mode without operator intervention. Automatic temperature control allows processing of input materials with different moisture content and bulk density.

- Zimmer America Recycling Solutions, North American agent for Germany’s STF Group, displayed STF’s new wet grinder at NPE. The unit was developed for both dry and wet shredding of post-consumer plastics and is available in two sizes and with any screen hole size between 8 and 50 mm. By adding water, the shredding process provides a combination of grinding and cleaning. During shredding, around 95% of the paper labels are removed and dissolved in the water.

- Commercial Plastics Recycling (CPR), the official recycling company for NPE2015, collected, sorted and recycled 191 tons of processing scrap, which was 62% more than was collected at NPE2012 and 235% more than at NPE2009, according to SPI: The Plastics Trade Association.

- A new partnership between Buhler Sortex of the U.K., (U.S. office in Stockton, Calif.), and NRT, Nashville, will help expand the companies’ presence in the PET and HDPE sorting segment, across Europe and North America. It also strengthens their position as the joint suppliers of combined plastic bottle and flake sorting solutions to the plastics recycling industry, with technologies such as in-flight sorting, PET boost, label reduction kit and smart-eject. The companies said they have several contracts already in place with major recycling operators.

- Working with an Ohio-based recycler Green Innovations, two film and sheet processors go landfill-free. The company believes its business model brings a realistic and cost-effective approach to recycling the waste that is generated at manufacturing plants. This article looked checked in with two processors that are currently working toward landfill-fee status to learn more about the process.

- A closer look at the potential impact of a circular economy. The EU recently released a call for the public to help develop a ‘circular economy’ and opened a public consultation to collect views on the main policy options for developing this ambitious new approach. Plastics Recyclers Europe believes this new circular economy package will be a boost to plastics recycling.

- TerraCycle has developed a Zero Waste Box that can recycle any pre-packaged beverage capsules used in capsule-specific machines to make hot beverages. The company launched the program about 18 months ago and has already collected 100 million capsules globally.

- The number of recycling firms in Taiwan has grown from about 100 in the 1980s and 1990s to more than 1,600 at present. According to Taiwan's Industrial Development Bureau of the Ministry of Economic Affairs, recyclers earned $2.2 billion in revenue in 2014, up from $1 billion a decade ago.

- U.S. plastic bottle recycling grew 97 million pounds in 2014 to top 3 billion pounds for the year, according to figures released jointly by the Association of Plastic Recyclers (APR) and the American Chemistry Council (ACC). The recycling rate for plastic bottles climbed 1% to 31.8% for the year.

- Using recycled plastics presents a big opportunity across the supply chain, which is one reason why the Society of the Plastics Industry (SPI), Washington, D.C., created the Re|focus Recycling Summit & Expo (April 25-27, 2016; Rosen Shingle Creek conference center and hotel in Orlando). In collaboration with its Recycling Committee, SPI has designed the event to assist brand owners and processors on their environmental goals.

Related Content

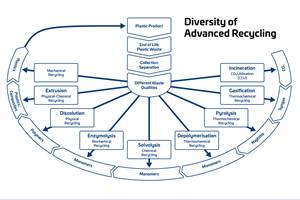

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More