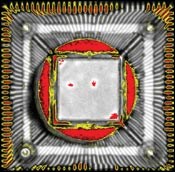

Ultrasonic Imaging Finds Voids, Cracks and Bonding Defects

As material costs climb, acoustic micro-imaging (AMI) is increasingly being used for non-destructive inspection and quality control of microelectronic components and assemblies, adhesive and welded bonds, solid part walls, and other applications where bond integrity, cracking, or voids are an issue.

As material costs climb, acoustic micro-imaging (AMI) is increasingly being used for non-destructive inspection and quality control of microelectronic components and assemblies, adhesive and welded bonds, solid part walls, and other applications where bond integrity, cracking, or voids are an issue. AMI analyzes the passage of ultra-high-frequency pulses of ultrasound through a material, which can reveal the presence of internal defects. Voids, cracks, and delaminations are usually associated with air gaps that reflect ultrasound at frequencies of 10 to 300 MHz rather than allowing its further transmission.

Plastics processors are making greater use of AMI due to the higher cost of materials and greater focus on quality improvement. “Companies don’t want to waste parts and they want to confirm that their process can manufacture good parts,” says Steve Martell, manager of technical support services for Sonoscan Inc., which reportedly invented AMI technology in 1973 and makes inspection systems for laboratory and production use.

Picture this bond

Determining the bond integrity between molded plastics and other materials has always been a difficult task for processors. Companies have traditionally relied on cutting a cross-section of the part in order to confirm the bond interface of glued, overmolded, or welded products. This destructive process is time consuming, and it is difficult to extrapolate the data from testing a small number of parts to the overall production process, says Tom Adams, a consultant with Sonoscan.

The benefits of AMI are its non-destructiveness and speed. It can take as little as 5 sec to scan a small part. The C-SAM, or C-Mode Scanning Acoustic Microscope, is an ultra-high-frequency ultrasonic imaging system that looks inside opaque samples and reveals internal features such as defects and construction details.

The system utilizes an ultrasonic transducer that scans the part. Since high-frequency ultrasound does not travel through air, a coupling fluid such as deionized water is used to deliver the ultrasound pulse from the transducer lens to the part surface. The transducer acts as both sender and receiver. A very short acoustic pulse enters the sample and return echoes from interfaces within the part are received at a rate of several thousand times per second. The return times are a function of the distance from the interface to the transducer and the material's acoustic properties.

An oscilloscope display of the echo pattern, known as an A-Scan, shows defects as areas of higher contrast in the image. An electronic gate “opens” for a defined duration, allowing only the information from a specific interface within the part to be imaged while excluding all other echoes. Completed C-SAM images of the internal structure of a sample are produced in about 10 sec.

AMI can be used on parts as large as 18 x 24 ft. A high-resolution scan of large parts can take more than 10 min.

Precise detection

The ultrasonic frequency determines the resolution with which defects can be detected. Generally, a higher frequency means a smaller wavelength and consequently a higher resolution. At 200 MHz, a 10-micron-wide defect can be detected, while at 100 MHz a 25-micron-wide fault is detectable. However, a transducer can actually detect defects an order of magnitude smaller than its resolution limit but not produce a resolvable image, says Martell.

AMI is used extensively in microelectronics where silicon chips are bonded to a plastic substrate. In those applications, AMI is incorporated in-line in the manufacturing process. Sonoscan also sees growing penetration in biomedical applications such as injection molded cartridges. AMI can verify bonds for most plastic materials except fiberglass composites. Acoustic imaging has limitations with high-glass-content materials because of its sensitivity to air gaps.

Sonoscan’s AMI inspection system is suitable for R&D, prototyping, manufacturing QC, and failure analysis. The company’s hardware and software packages range from $175,000 for the base model up to $250,000 with options. Part testing is also offered as a laboratory service in the U.S., Europe, and Far East.

Related Content

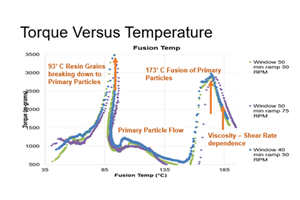

Try This Alternate Method for Heating Your Torque Rheometer

Rheometers are generally not on all the time. And most users have found that the first test run in the instrument after heating up is not very reliable and is usually discarded. Try this method instead.

Read MoreDatacolor Acquires Matchmycolor

The acquisition of the specialist in color formulation and communication software further expands Datacolor’s global industry presence in color management.

Read MoreX-Ray Vision Inside Parts Gets More Affordable for Processors

Shimadzu’s new benchtop x-ray CT scanner provides internal and external metrology and flaw detection at a fraction of the previous cost.

Read MoreDual-Mode Portable Thickness Gauge for Packaging

Hand-held “pen” measures sheets, containers, panels, large parts with magnetic or capacitance mode; controlled by Bluetooth phone app.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)