UV Cure Solves LSR Processing Challenges

Close Up: LSR

Extended cure times for thick parts and temperature sensitivity of pharmaceutical additives are two challenges for silicone molding and extrusion that can be overcome with new low-temperature UV curing technology.

Extended cure times for thick parts and temperature sensitivity of pharmaceutical additives are two challenges for silicone molding and extrusion that can be overcome with new low-temperature UV curing technology. That’s the word from Momentive Performance Materials Inc., Albany, N.Y. (momentive.com), which showed off its new Addisil UV 60 EX elastomers at the MD&M West medical show in Anaheim, Calif., last month.

At MD&M, the new technology was presented by Specialty Silicone Fabricators (SSF), Paso Robles, Calif., with assistance by Momentive. SSF performed tests on LSR “combination products,” in which drugs are mixed into the silicone formulation for extended-release applications. Four different drugs (three steroidal types and one antibiotic) were tested in a 64 Shore A LSR, demonstrating that the drugs did not inhibit cure at room temperature. And NMR testing of cured LSR containing one anti-inflammatory drug showed that the UV process did not degrade the drug.

As explained by Mark Paulsen, business development director of SSF, this is significant because many pharmaceuticals are sensitive to heat. “Low-temperature UV-curing of LSR has the potential to expand the scope of silicones in combination products and expand the range of drugs that can be used in them,” he said. While room-temperature vulcanizing (RTV) silicone elastomers offer an option, they cure very slowly—from 30 min to as long as three days. The UV LSR plaques in these tests cured fully in 40 to 100 sec.

HOW IT WORKS

Momentive’s Silopren UV LSRs and Addisil UV EX extrudable solid (HCR) silicone rubbers are two-part formulations that contain a UV-activated platinum catalyst. Momentive application development engineer Mel Toub says these materials can be cured with common UV lamps that emit light in the wavelength range of 315 to 430 nm.

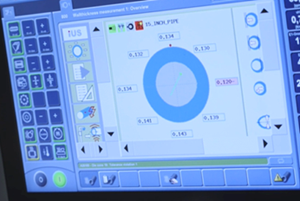

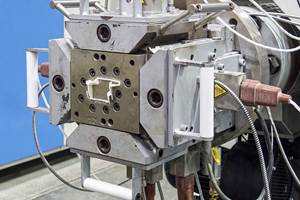

UV curing of LSR does require transparent molds or cavity inserts. For extrusion, the UV light is provided externally using a modified lamp fixture, while molding requires transparent molds or cavity inserts. Tests so far have used machined blocks of acrylic for molds; Momentive and SSF are exploring more durable alternatives.

The LSR (or HCR) formulation must also be relatively clear but can accommodate bright, vivid transparent colors, as long as the pigments are compatible with platinum catalysts. Silopren UV LSR is available in 54, 64, and 68 Shore A hardnesses. According to Toub, properties are comparable to those of heat-cured LSRs. He notes that the UV-cure process has a number of other potential advantages: There may be no need for a water-cooled injection barrel or cold deck on the mold, which can reduce tooling costs. Since mold filling is accomplished at room temperature, there is virtually no risk of scorching. Low-temperature curing also means no pressure buildup in the mold and lower post-mold shrinkage. Toub says premixed UV-curable material has a long pot life, even under exposure to indoor fluorescent lighting (but sunlight must be avoided).

UV-cure extrudable silicone was first commercialized in Europe but is now also available here. Toub sees big opportunities in UV-cure LSR molding, not just for medical combination products, but also of thick-wall parts where current cure times are very long, and UV cure offers significant cycle-time reduction.

Related Content

Fully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreTeel Adding Capacity, Bumping Pay for Hourly Workers

Teel growing to meet market demand, meaning increased employment opportunities for the area.

Read MoreBelling Machine Forms 'Rieber' Socket in PVC-O Pipe

Italy’s SICA has developed an innovative Rieber belling process specific for PVC-O pipes. At the same operating pressure, these pipes require a wall thickness of about 35-40% less than those in conventional PVC pipe and allow the construction of water supply pipes up to 25 bar of operating pressure.

Read MoreIs Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More