Virtual Reality Software Saves Time & Cost in Color Formulation

Color is a measurable property, but it is also a subjective quality dependent on individual perception.

Color is a measurable property, but it is also a subjective quality dependent on individual perception. And therein lies the source of the biggest headaches for color specifiers and formulators alike. How does the customer communicate, “This is the color I want”? And how does the compounder reply, “Is this color close enough?” What does the compounder do when the customer says, “No, I want it lighter, brighter, greener”?

Until recently, the only answer has been to ship physical samples—such as fabric swatches and color chips—back and forth between supplier and customer until an agreement is reached. The industry has been looking for a less cumbersome, costly, and time-consuming alternative for years. Makers of color measurement instruments and software have made several attempts at a solution, but none has caught on. So a few color compounders have taken it upon themselves to solve this puzzle. One is Techmer PM, Clinton, Tenn.(techmerpm.com). The company has used computerized color matching and QC for 25 years, but it first revealed its work on a color visualization system for communicating with customers in 2004. Called TechmerVision, that system has gradually evolved and took a major step forward in the last two years with the addition of virtual reality software from Datacolor, Lawrenceville, N.J., that shows physical representations of plastics and fabrics with realistic simulation of the way different types of ambient light interact with surface texture and gloss.

AUTOMOTIVE FIRST, THEN PACKAGING

“The automotive industry is notorious for being very demanding of its suppliers,” says John Manuck, Techmer president and CEO. “And the industry has become more complex, with suppliers all over the map—and even all over the globe—using a wide range of plastics and fabrics that must match each other. With the growth of integral coloring, those materials’ differences are no longer covered up with paint, so the probability of matching problems and metamerism issues is much higher.”

“Also, Detroit is accelerating its color development cycle. What was 36 months is maybe 18 to 24 months now,” adds Jim Harper, director of color development. “And all too often, color-fade failures are detected only after months of weathering tests. By predicting UV-stable formulations, we’re reducing color-development risk using virtual color visualization.”

Those are reasons why TechmerVision was first aimed at auto interiors. “Auto

companies have typically developed their color schemes without involving a colorant manufacturer,” says Jack Murphy, Techmer’s new automotive market manager. “But the OEMs have fewer people on staff today. We want to be involved earlier in the upfront design stages. Working with realistic-looking color samples on a computer screen helps make that possible.”

The next phase of TechmerVision will be for packaging, which has a time-sensitive seasonal and fashion component, says Harper. Movement in this direction was partly instigated by Techmer’s 2008 acquisition of Accel Color, which was heavily involved in packaging, especially closures.

HOW IT WORKS

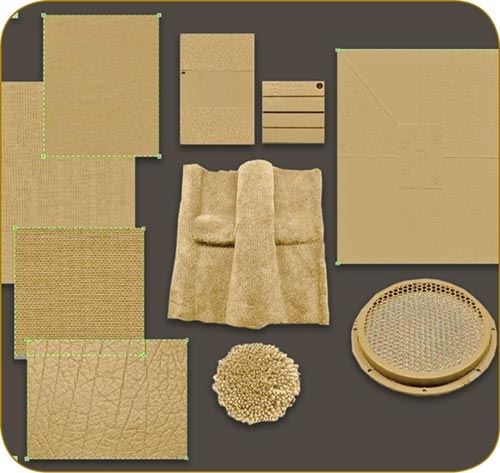

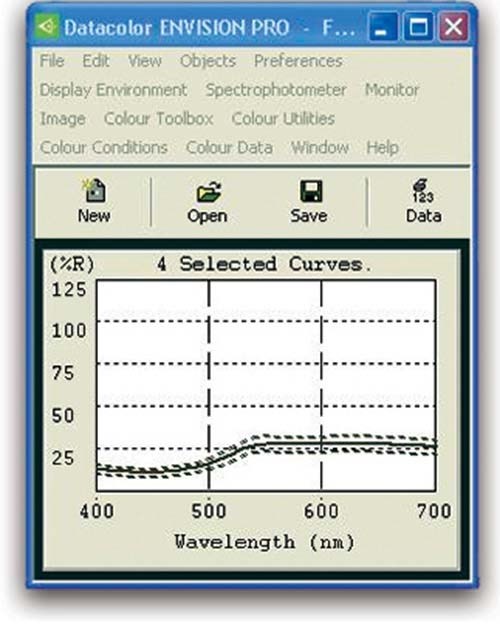

The first step in the evolution of TechmerVision was compiling the TechmerColor database of color-measurement data on some 27,000 colors in many kinds of polymers and fabrics with different textures, illuminants, and flat and curved surfaces. “This is the product of years of data gathering, using real-world color curves from measuring actual samples,” says Harper. Next, the company generated an extensive primary library for each pigment and resin, allowing Techmer to apply its color-matching expertise to both the manufacturing process conditions and the product end-use, so as to predict an achievable formulation that can be simulated with TechmerVision.

Techmer’s initial target audience is designers at automotive OEMs and Tier 1

suppliers. Using a laptop computer, a Techmer representative can work with a customer’s color designers to select a substrate—fabric, leather, or plastic—and play around with different colors and lighting conditions. For an automotive customer, the selections would be from a specific automotive database including materials such as PET, nylon, PP, and TPO. The customer can use on-screen sliders to adjust lighting, hue, and chroma to get a desired look. The results of any slider setting are displayed in actual color-measurement units. In addition to selecting results based on color harmony and metamerism, the customer can select for non-color factors such as weatherability and cost. “Because it’s based on our real-world data, we know that any color you choose with our software actually can be made,” says Harper.

When a color is finally selected, the customer gets an actual physical color

sample to match the appearance on screen. “Theoretically, the customer could

go anywhere to get that colorant made,” says Manuck. “But there’s a lot more to it—how you make it counts. You must lot-select pigments, and so forth. We’re selling reliability and reproducibility.”

Techmer’s goal is to license its visualization software with a portion of its

color database matched to the particular customer’s industry. Techmer has licensed portions of its TechmerColor database, but has not yet licensed its visualization software. “It’s inevitable that these systems will gain more traction,” says marketing director David Turner. “Each year, we see more of the design process going digital.” With TechmerVision, Techmer expects to cut color approval times in half.

Related Content

Graphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Read MorePFAS-Free Processing Aid for Blown Film Extrusion

Ampacet’s new processing aid said to perform as well as fluoro-based PPAs in blown film.

Read MoreK 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

Read MoreCrosslinking Process Promises Thinner, Higher-Performance PE Films

Technology combines UV curing system with photo initiator promoter masterbatch.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More