WEIMA Group Celebrates 30 Years

Europe remains the strongest individual market followed by the U.S. WEIMA America generates a quarter of the company's overall earnings.

WEIMA, Ilsfeld, Germany, is celebrating its 30th anniversary this year.

"Since its establishment in 1986, WEIMA has sold around 30,000 shredders and briquette presses. Whereas the machines used to be operated in the background, they have now been integrated into the overall production process," said Martin Friz, the managing director of WEIMA Maschinenbau, GmbH. “WEIMA now boasts a team of over 200 employees worldwide, and we are still growing stronger with each year.”

Half of WEIMA's market share comes from the wood industry worldwide. The other half of WEIMA's market share comes from a variety of other industries, including paper, plastics, data destruction, and the waste-to-energy sector.

Europe remains the strongest individual market followed by the U.S. WEIMA America, Inc. generates a quarter of the company's overall earnings. As the company continues to expand, its sights are set on other international markets including China, India, and Southeast Asia. South America-- Brazil, Argentina, and Chile specifically. In the past years, the company has made significant investments in enhancing the facilities in Saxony-Anhalt in Germany and the US. It will follow suit with its Ilsfeld facility this year. The company is currently also establishing its first sales and service subsidiary in Northern China to provide specific solutions to individual sectors on the Chinese market.

“Since our company was established, we have served businesses of all sizes, from small workshops to large industrial companies. Providing size reduction solutions for companies of all sizes will remain our focus,” Friz said. “However, companies are no longer asking about the machines’ functionality. That’s a given. Instead, companies are wanting to know more about efficiency, noise emissions, or the environmental footprint of the machine. Most of all, integration into the production line has become more important.”

Traditionally, noise emissions were controlled by soundproofing the area around the machinery. WEIMA has recognized the demand and responded to the call— in the second half of 2016, WEIMA will unveil products where sound insulation is integrated into the machine itself, reducing noise emissions even further.

In the last few years, WEIMA has noticed that customers are investing in fewer and fewer stand-alone solutions. Today’s customers seek a more comprehensive approach where shredders are integrated into the production line in order to optimize the process and save time. As a result of this, every PLC-controlled machine that leaves the WEIMA warehouse features a network interface option.

“WEIMA was once primarily mechanical manufacturer, but these days the company is also driven by IT. At WEIMA we are a machine manufacturer, not a supplier of complete systems," Friz said. “Consequently, we must provide clearly defined interfaces that meet all system supplier requirements. This is a complex process because we must be compatible with all formats. However, we can fall back on expertise that enables us to find the right solutions to the requirements of our system suppliers. In this context, we provide entire, completely programmed assemblies including the required interfaces for complete system integration.”

In the U.S. market, preventative maintenance is absolutely key to maintaining a system. The majority of WEIMA machinery is sold with service agreements for preventative maintenance—that is, proper care of the machine over time to ensure its longevity and efficiency in shredding and briquetting. This way, suitable maintenance measures are carried out at intervals that suit its customers’ needs and prevent down time. Southeast Asia is also on board with the trend of preventative maintenance, and Friz has hopes that the European market will soon begin to also embrace this development. It will become part of the product range, whereby maintenance is either carried out by the retailer or the manufacturer.

“WEIMA has come a long way from its humble beginnings. These days, we provide full vertical integration,” Friz said. “Our machine production starts with the production of the steel structure itself, and continues from rotor processing to the production of an individual gearbox. Our production depth is at its highest today. This also comes as a result of the increasing production of individualized concepts and turnkey solutions in collaboration with external partners. These projects would otherwise not be feasible from a time or cost perspective. Consequently, we are heavily investing in production depth to quickly meet all customer demands and maintain an identically high level of quality.”

Related Content

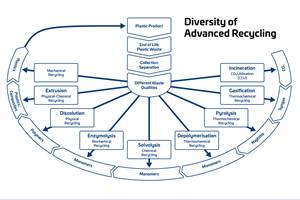

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreA Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreReversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

Read MorePurpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More