Will Oil Price Changes Continue to Be a Key In PE Pricing?

Oil prices just rallied above the $50/bbl mark; this, while PE prices continued to decline this month.

Oil prices just rallied above the $50/bbl mark; this, while PE prices continued to decline this month.

Within the last four to five years, crude oil prices have been one of the key drivers influencing PE pricing. Plunging oil prices this year helped keep PE prices relatively stable until September when suppliers successfully implemented a 5ȼ/lb increase; this owing to tightened supply at the time.

In fact, the September PE price was the highest since January 2015, when crude oil first dropped to $45/bbl from $90/bbl. Also that month, domestic commodity PE film processors followed suit by announcing price hikes of 6%.

At that time, I spoke with Mike Burns, Resin Technology, Inc.'s (RTi) v.p. of client services for PE, and he cautioned on likely competition from imported finished PE goods that could emerge following this action. Burns emphasized the influence of the plastic bag market on overall PE pricing by noting these key factors:

Nearly 40% of PE sold is used for film applications: retail bags, garbage bags, food packaging, construction, medical supplies, etc.

Cost to produce a retail bag, grocery bag or can liner in China/Southeast Asia and deliver to a North American city is 25ȼ/lb over the cost of resin.

Cost to produce a retail bag, grocery bag or can liner in North America and deliver to a North American city is also 25ȼ/lb over the cost of resin.

Note: In 2015 and 2016, the average cost to produce and deliver PE pellet derived from oil/naphtha was near 45ȼ/lb; for that same time frame North America’s average cost to produce and deliver PE pellet from shale gas was 30ȼ/lb).

North American PE suppliers need to keep film production in North America.

When the price delta exceeds 10%, retailers call China/Southeast Asia.

Although Burns, and other industry pros, initially thought PE suppliers would aim to hold on to that 5ȼ/lb margin gain through year’s end, by the October-November time frame, things were looking quite different. Industry dynamics, including suppliers’ growing inventories, sluggish export demand, some softness in domestic demand, and lower prices abroad hampered that aim.

Burns had noted that “something had to give”. He pointed out that PE contract prices were now 5ȼ above what they should be. At the same time, spot prices were as much as 10ȼ/lb lower vs. a more typical 5-7ȼ less than contract prices. Ditto for export prices which were 15ȼ lower vs. a more typical 7-10ȼ less than contract prices.

By early November, PE suppliers offered price concessions of 3 cents/lb, and some signaled further drops for December on the order of 2-5ȼ/lb, with 2-3ȼ, a more realistic expectation, ventured Burns. Speaking with Burns on December 1, regarding what might happen in January, he noted that if crude oil prices moved up to an expected $50/bbl, that may stop any further PE decreases, but will not result in increases. Only if oil prices rise beyond $55/bbl, will shale gas prices also move up, as will PE prices, he ventured.

Which bring us to Monday, Dec. 12, when nearly a dozen non-OPEC producers agreed to reduce their crude oil output in support of OPEC’s efforts to prop up prices. Prices jumped to $53.95/bbl, with some analysts talking about a $60/bbl or more emerging.

However, the U.S. Energy Information Administration (EIA), in its latest Short-Term Energy Outlook stated that the resurgence of U.S. shale will undermine the OPEC-fueled price rally, putting a cap on oil prices at about $50/bbl through 2017. The EIA also is doubtful on how much OPEC will actually follow through on its deal.

“The extent to which the announced plans will be carried out and actually reduce supply below levels that would have occurred in their absence remains uncertain.” The agency ventures that an above $50/bbl rally will simply serve to revive U.S. shale drilling, which will “encourage a return to supply growth in U.S. tight oil more quickly than expected.”

Back to RTI’s Burns, whose 2017 forecast is based on RTi’s naphtha resin cost model; namely, naphtha has a close10:1 ratio with oil—it moves very close to oil price movements. Every $2/bbl change in oil prices equals approximately 1ȼ/lb in the cost to make a pellet from naphtha. As such, every $10/bbl price movement above or below $50/bbl will increase or decrease the PE price 4-5ȼ/lb.

Related Content

Flexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

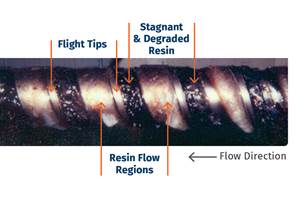

Read MoreHow Screw Design Can Mitigate Gels in PE Films

Gels are a constant issue in production of PE films using single-screw extruders. Gels can create quality issues via optical flaws, and they can cause the film to break on blown or cast film lines. There are numerous origins for gels, and the mitigation method depends on knowing the gel type.

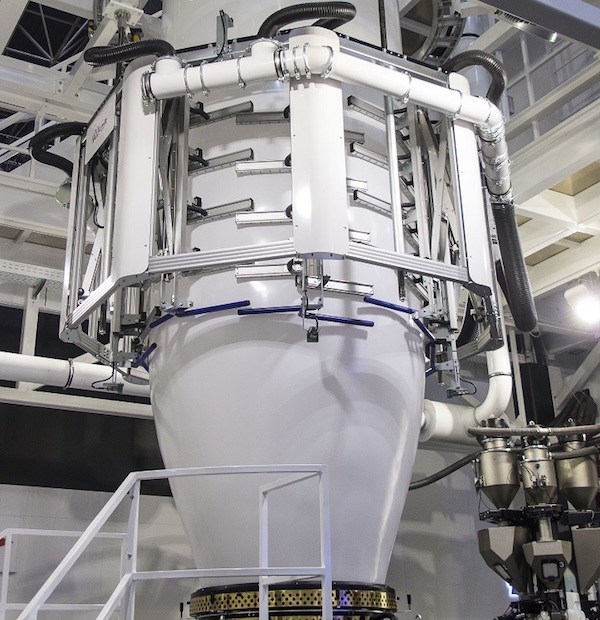

Read MoreAir Ring Add-On Brings Output to New Level

The Short Stack from Addex sits between the air ring and die and provides high-velocity air flow to boost output and lock in the bubble.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More