Wood-Filled Plastics: They Need the Right Additives for Strength, Good Looks, and Long Life

Wood-plastic composites, or WPCs, are already a 1.3-billion-lb market and are growing at 20% annually.

Wood-plastic composites, or WPCs, are already a 1.3-billion-lb market and are growing at 20% annually. That’s big enough to draw increasing attention from additives suppliers to the particular needs of WPC applications in residential decks, railings, fencing, doors, window frames, outdoor spas, and gazebos. Work is also under way on siding and roofing. Suppliers are busy identifying optimum choices of existing additives and developing new ones to give WPCs better physical properties, surface appearance, and long-term durability.

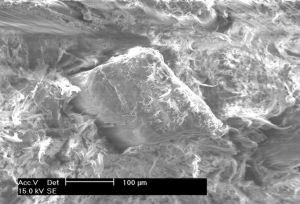

Proper additive choices for WPCs are critical to both performance and processing. Decking products have not proven to be as "maintenance-free" as originally touted. Warpage, splitting, staining, and discoloration problems have surfaced in some cases. As WPCs attempt to move into more structural load-bearing uses, additives that build mechanical strength are an urgent goal. And on the extrusion line, processing additives are essential to achieving both economical line speeds and smooth surfaces without so-called edge tearing.

The most critical areas of additive selection for WPCs are coupling agents, lubricants, and colorants, with chemical foaming agents and biocides not far behind. Selection of specific types for WPCs depends on the base resin. Polyethylene-based wood composites—mainly recycled HDPE—account for 80% of the market. Wood-PVC is 10% to 13% and wood-polypropylene, 8%. Wood-polystyrene accounts for only 1% to 2%.

Coupling for strength

Coupling agents bond the wood fiber to the resin matrix. They boost the flexural strength and stiffness—usually referred to as modulus of rupture (MOR) and modulus of elasticity (MOE), respectively, which are terms used in the lumber industry. Coupling agents also improve dimensional stability, impact resistance, and fiber dispersion, while reducing creep. Added strength is important in railings, stair treads, fencing and in structural applications. But in decking, coupling agents are used mainly to reduce water absorption, which swells the wood fibers near the surface of the board, causing stresses that can lead to cracking.

Coupling agents are especially valuable in polyolefin WPCs because they overcome the incompatibility between the polar wood chemistry and nonpolar resin matrix. In the lead are chemically modified (usually maleated) polyolefins made by grafting maleic anhydride onto the polymer backbone through reactive extrusion. They generally sell for around $1.50/lb and are used at levels of 1% to 2%.

Newer developments in clude chemically modified polyolefins that are not made by grafting, long-chain chlorinated paraffin, and reactive coupling agents for wood-PVC.

Crompton Corp. recently launched Polybond 3029MP, a maleated HDPE in a new smaller particle size—20-mesh micropellet—that’s said to improve dispersion. At 2%, it reportedly can double the flexural and tensile properties of 60% wood in HDPE.

Crompton also has a proprietary maleated PP that reportedly outperforms coupling agents made by reactive extrusion, partly owing to the ability to incorporate higher maleic anhydride (MA) levels. Trials are said to show significantly higher tensile, flexural, and impact strengths with this additive, less susceptibility to lubricant interference, and 40% lower water absorption.

Equistar Chemical offers the Integrate series of maleated PE coupling agents for PE-based composites, plus new maleated PPs for wood-PP. Jim Krohn, business development manager, claims that wood-PE lumber typically shows at least 50% higher MOR and 20% higher MOE with these additives.

DuPont offers MA-grafted Fusabond MB-226D for wood-PE and MD-353D for wood-PP. Tensile strength in wood-HDPE is said to be 200% to 300% higher than uncoupled formulations. DuPont has also developed a new chemistry that replaces grafting with proprietary copolymers made from anhydride-functional monomers that are said to work well in wood-PE.

Eastman Chemical offers Epolene MA-grafted coupling agents such as PE-based Epolene G-2608 and newer PP-based E-43, G-3003, and G-3015 grades. "We have seen a 70% increase in overall tensile properties, 30% to 35% increase in MOR, over 200% in unnotched Izod impact, about 20% improvement in HDT, and dramatic increases in moisture resistance," says business development manager Damon Hollis.

Dover Chemical is offering a long-chain chlorinated paraffin (LCCP) as a non-reactive coupling agent that appears to improve strength retention of HDPE and PP WPCs during moisture cycling. Unlike maleated olefins, which tend to detract from lubrication properties, LCCP reportedly increases lubrication, as well as uv and moisture resistance. According to Dover’s data, the LCCP yields higher flex modulus and tensile strength than a standard zinc stearate/EBS formulation of 60% wood in HDPE; however, the extruder torque was higher with LCCP. But when combined with a proprietary lubricant in a one-pack system (Doverbond DB 4300), both lower torque and higher physicals were achieved. In fact, the lubricated system has higher stiffness and strength than the unlubricated control, unlike the stearate/EBS sample. MOR of PP and HDPE with 60% wood is 40% higher with DB 4300 than with stearate/EBS, adds business manager Tom Kelley. Listing at $1.50/lb, the one-pack can be used at 3% to 5% in place of 1% to 2% of a typical coupling agent plus 3% to 5% of traditional lubricants.

Clariant Additive Masterbatches offers two compatibilizer concentrates. Cesa-mix 8611 is a functionalized copolymer for use in PE and PP, and Cesa-mix 8468 is a highly functionalized system that’s said to improve surface quality of wood-PP. New developments for compatibilizing wood-PVC are in the works at Crompton. The issues are different than with polyolefins because both wood and PVC are polar. "But wood has a lot of acid on the surface that degrades PVC, while PVC generates hydrochloric acid that degrades wood," explains Dr. Peter Frenkel, R&D director for vinyl additives. One solution is to treat the wood fibers with a sizing stabilizer before compounding. Mark W15 is a new, proprietary wood sizing agent that acts both as a compatibilizer and heat stabilizer and significantly improves tensile and flexural strength.

Crompton is also developing a new reactive compatibilizer for wood-PVC. It is designed to be mixed into the PVC matrix to make it compatible with wood fiber and improve properties.

Lubricants are essential

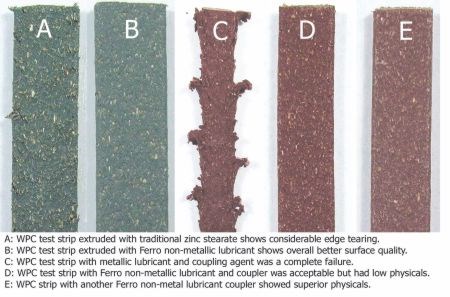

Lubricants increase throughput and improve WPC surface appearance. WPCs can use standard lubricants for polyolefins and PVC, such as ethylene bis-stearamide (EBS), zinc stearate, paraffin waxes, and oxidized PE.

EBS with zinc stearate is widely used in wood-HDPE. However, there are new alternatives because metal stearates are known to decouple the maleic anhydride of maleated coupling agents, canceling the effectiveness of both lubricant and coupling agent. These new lubricants sell for around $1/lb vs. 70¢ to 90¢/lb for EBS and zinc stearate.

WPCs use about twice as much lubricant as standard plastics. For HDPE with a typical 50% to 60% wood content, lubricant level can be 4% to 5%, while a similar wood-PP composite typically uses 1% to 2%. Total lubricant level in wood-PVC is 5 to 10 phr.

Struktol has a new proprietary lubricant package, TPW 104, for wood-polyolefin composites. It contains zinc stearate and therefore is not recommended for use with maleic anhydride coupling agents. Also new is TPW-113, a package with non-metallic lubricant for wood-polyolefins. For wood-PVC, Struktol offers TPW-012 and TR-251 lubricant packages, which combine standard rigid PVC lubricants with some "unique chemistry," says product manager Mike Fulmer.

Lonza Group has developed a more advanced alternative to its standard EBS (Acrawax C) plus zinc stearate. Glycolube WP-2200 is a new proprietary amide lubricant that contains no metallic stearates. It reportedly performed well in wood-HDPE field tests and has potential for wood-PP and wood-PVC composites. Recent trials showed a reduction of overall lubricant use from 4.5% to 3% while delivering over twice the extruder throughput.

Crompton offers fatty-acid-based lubricants for wood-polyolefins. These include metallic stearates, amides, and esters. Lubricants for wood/PVC composites include both internal and external Marklube lubricants.

Clariant Additive Masterbatches offers Cesa-process 9102, a fluoroelastomer for extrusion of wood-polyolefins. Cesa-process 8593 and 8633 are proprietary lubricant systems for wood-polyolefin extrusion. Cesa-process 8477 is a highly loaded fatty-ester system for wood-polyolefin extrusion and injection molding.

Ferro Corp.’s Polymer Additives Div. has developed two new series of lubricants for WPCs. The SXT 2000 series blends metallic stearates with non-metallic lubricants for wood-polyolefins. The SXT 3000 series is totally free of metallic stearates. Although SXT 3000 costs more per pound, it is so effective that it is possible to reduce lubricant loading while still achieving improved throughput and product quality, according to lubricants technical manager Louis Brandewiede. Both lubricant families have shown significant increases in output—up to 50% more than traditional rates.

Reedy International, supplier of Safoam endothermic chemical foaming agents, is offering three new lubricants for foamed WPC composites. Safoam WSD is a lubricant and antioxidant that is applied to the wood flour. It is designed for PP and PVC containing up to 70% wood.

Safoam WLB is a reportedly unique HDPE wax external lubricant for PVC, PP, and HDPE composites. It reportedly allows very low use levels.The third product is a highly branched, ester wax internal lubricant designed to allow the wood fibers to wet out better than with EBS/metal stearate combinations.

Colorants for WPC

Colorants are used to provide both a wood-like appearance and uv resistance. Masterbatch suppliers are using colorfast, highly reflective, and weatherable pigments to satisfy demand for better color-fade resistance at the lowest possible cost. Pigment levels must be 1% to 3% or higher to overcome color staining from the wood. Color concentrates tailored for WPCs typically include lubricant and often are customized multifunctional packages that may include coupling agents, antimicrobials, and uv stabilizers.

Accel Corp., which has been active in WPCs for over 10 years, offers customized color and additive masterbatches for wood-PE and wood-PVC composites.

Ferro’s Plastics Colorants Div. has introduced standard wood-polyolefin colors such as teak brown, cedar, weathered gray, and redwood, as well as custom color matching in concentrates, liquids, and non-dusting granules.

Clariant Masterbatches offers tan, dark red, gray, and oak standard masterbatches, as well as custom colors, for PE, PP, PVC, and PS composites. Colorants are tailored for wood contents from 30% up to 70%.

Techmer PM has introduced redwood, cedar, brown, white, and black- colorants for polyolefin and PVC wood composites.

Chemical foaming grows

There is keen interest in chemical foaming of WPCs to reduce weight and materials cost and to improve surface appearance, processing speed, and ease of sawing, nailing, screwing, and painting finished products. About 20% of all WPC products—mostly wood-PVC—are currently foamed.

Both endothermic and exothermic chemical foaming agents (CFAs) are used. Foaming is tougher for crystalline polymers like PE and PP than for amorphous polymers like PVC and PS, as the latter generally have better melt strength. When higher wood content is added to the mix, as in polyolefin decking products, the challenge is particularly daunting.

Says Bill Crostic, president of wood-polyolefin compounder Onaga Composites, "We see CFAs finding a niche in fence and exterior trim boards and less in decking, where wood content can be as high as 70%." He points out that the more wood is present, the less resin there is to be foamed.

While it’s not easy, Mike Reedy from Reedy International says foaming of higher wood-content WPCs can be done with the right materials, additives, and processing conditions. He cites the example of a new 65%-wood PP composite decking product produced with Safoam CFAs and lubricants on a conical counter-rotating twin-screw extruder. The result is 0.788 g/cc density—30% to 35% lower than unfoamed wood-polyolefins.

Clariant’s Additives Masterbatches Business unit offers the Hydrocerol PLC series of CFAs, which include endothermic, exothermic, and endo-exothermic blends for polyolefin, PVC, and PS wood composites. Says new business development manager Dennis Haff, "People who are using our foaming agents typically have below 50% wood content, which allows for meaningful foaming potential."

Bergen International has seen its Foamasol CFAs used in PVC, polyolefin, and PS wood composites, primarily for decorative moldings such as siding trim boards, railings, and spa panels, where loss of physical properties from foaming is not an issue. "Most of our customers are using wood content in the 20% to 30% range. We aim at weight reduction of 5% to 10%, says president Dennis Keane.

Crompton offers its Celogen family of exothermic CFAs, which can be used to foam wood-polyolefin and PVC composites. Techmer PM has three new standard CFA masterbatches for wood-polyolefins. These are typically custom formulations including color and other additives. The products include exothermic types and endo-exothermic blends with different loadings and decomposition temperatures.

Accel Corp. offers both endothermic and exothermic CFAs, typically in a multifunctional additive and color masterbatch for wood-PE, wood-PVC, and more recently wood-PP decking and fencing.

Combating mold & mildew

Mold, mildew, and stains on some WPC decking are driving manufacturers to consider antifungal biocides that protect either the plastic component and maintain its surface appearance or that preserve the wood component from decay and also reduce moisture absorption. Many products purport to do both.

Weathering and uv radiation have been shown to degrade the surface of WPCs within a few weeks of exposure. "They tend to get lighter after initial installation as the colored extractives and lignin from wood fibers are removed by rain. With continued exposure, loosening of the wood fibers and breakdown of the plastic component follow color change. Also, moisture can lead to a loss in mechanical properties and provide a more favorable environment for fungal growth," explains Gerry Capocci, market manager at Ciba Specialty Chemicals.

Ciba offers Irgaguard F3000, a thiazolyl benzimidazole said to be a broadly effective fungicide for wood-polyolefin and wood-PVC composites. Developmental EB 43-25 combines Irgaguard F3000 with a proprietary additive. It is both a broad-spectrum fungicide and can eliminate or reduce stains due to interactions of iron, tannin, and moisture.

U.S. Borax offers Borogard ZB zinc borate as a preservative for wood-polyolefin and wood-PVC composites. It has broad-spectrum activity against wood-destroying organisms plus heat and uv stability and resistance to leaching and weathering, according to technical manager Mark Manning.

"Laboratory evaluations of commercial WPC products against wood- destroying organisms such as decay fungi and termites have shown weight losses of 10% to 20% in as little as four months, which equates to 20% to 40% weight loss in 50/50 wood-plastic WPCs," says Manning. But when Borogard ZB was added to HDPE decking with 50% to 70% wood, weight loss was less than 1.1%, he reports.

Rohm and Haas sells Vinyzene biocides, which are based on dichloro-octyl-isothiazolone (DCOIT) for wood-PVC composites. Newly commercial Vinyzene SB27 is a concentrate of DCOIT in a vinyl carrier.

The company is also field testing new SB27-ELV, which is 10% DCOIT in a polyolefin terpolymer, aimed at wood-polyolefin composites. This leaching-resistant and uv-stable product is said to be effective at 0.04% to 0.1%.

New developments for treating natural lumber planks also have potential for treating the wood flour used in WPCs to prevent color change. Lonza introduced an alternative to chromium copper arsenic (CCA), a carcinogenic wood preservative banned by the EPA in Dec. 2003. Lonza’s Carboquat is a quaternary ammonium compound that could be used to treat wood flour for WPCs. Ciba also has a new proprietary wood treatment that is ready for sampling. Struktol is working on anti-staining wood lubricants that will neutralize tannins.

Substitute talc for wood?

Replacing some of the wood flour and resin content of wood-HDPE and wood-PP products is a major R&D focus at talc supplier Luzenac America. Trials of HDPE with a 60% filler loading (33% wood/27% talc) reportedly show significant improvement in MOE and MOR, HDT, and creep performance. Throughput increases 15% when 10% of the wood in a formulation is exchanged for talc, Luzenac says. Throughput gains of up to 37% result with a 50% talc-for-wood substitution. Moisture absorption is also much lower.

Related Content

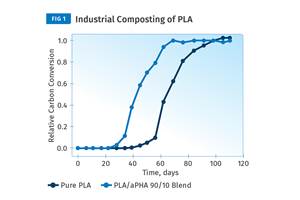

Blend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More