Biodegradable plastic market adds a new player in China

Air pollution grabs headlines in China, but a country of 1.35 billion with a growing middle class spending newfound disposable income on single-use disposable plastics is bound to have issues with solid waste as well.

Hoping to address those and tap into increasing regulation of plastics bags in the country, Jinhui Zhaolong High Technology Co. Ltd. offered details on its new 20,000 m.t./yr production line for a biodegradable plastic it’s positioning as a “green” replacement for traditional plastics in a range of products from shopping bags to mulch films. In addition to output, the company touted the production technology for the polybutyrate adipate terephthalate (PBAT), which it dubbed Ecoworld, saying it utilizes a one-step polymerization process.

Janice Li, VP Shanxi Jinhui Group, presented the news at a pre-Chinaplas 2014 press conference sponsored by show organizer, Adsale. Jinhui Zhaolong, which is a wholly owned subsidiary of Chinese coal interest, Shanxi Jinhui Energy Group, was created in 2012 in the Xiaoyi Economic Development Zone.

Jinhui Zhaolong says its initial investment gives it the largest capacity for PBAT in Asia. Globally, BASF is the dominant producer with its Ecoflex brand of PBAT materials. In February 2011, it expanded production of the biodegradable plastic at its Ludwigshafen, Germany facility, boosting output from 14,000 to 74,000 m.t./yr, as well as expanding capacity for its Ecovio material, which blends Ecoflex with polylactic acid (PLA). Elsewhere in Europe, Italy’s Novamont has PBAT production at its biorefinery in Terni, where it manufacturers its Origo-Bi material. That’s based on Eastman Chemical’s Eastar Bio copolyester, which Novamont acquired in September 2004. Started up in 2008, the Terni biorefinery has total annual production capacity of 80,000 m.t./yr for both its PBAT, trade name Origo Bi, and starch-based bioplastic, Mater-Bi.

Targeting PE

Jinhui Zhaolong describes its Ecoworld PBAT as a terpolymer made from 1,4 butanediol, adipic acid and terephthalic acid. It touted its tear resistance and impact strength versus polyethylene, which it’s targeting in applications like mulch film and bags, saying it provides 120% and 130% of the tear resistance and impact strength, respectively, of PE.

The company said its material has been shown to decompose via microorganisms into carbon dioxide and water in 180 days, satisfying European Union EN13432 and U.S. ASTM 6400D biodegradability standards. In addition, it has completed Chinese and FDA food contact requirements. In terms of properties, Ecoworld’s blowmolding grade has a density of 1.26 g/cm3, with a melting point of 115 C.

Using starch and CO2 to create a better barrier

The company also promoted the development of what it called a “degradable composite” barrier material that’s based on polypropylene carbonate (PPC) and made in part from carbon dioxide. This development, was presented by Yuezhong Meng, a professor at Sun Yat-Sen University in Guangzhou.

Meng, who said he has more than 52 patents for the related technology, including three from the U.S., said the finished polymer is composed of about 40-50% carbon dioxide, with a one-step reaction utilized to create the polymer. Meng touted PPC’s oxygen barrier, water permeability, and cost, as compared to competitive barrier materials including PVDC and EVOH.

From a property standpoint, Meng compared the material to polypropylene, noting that it has a process temperature ranging from 170-250 C, with tensile strength of 24.2 (MPa) and elongation at break of 5.64%.

Novomer, Waltham, Mass., which bills itself as converting carbon dioxide into sustainable polymers and chemicals, also markets a PPC created by joining propylene oxide and carbon dioxide in the presence of a proprietary catalyst.

Related Content

Resins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

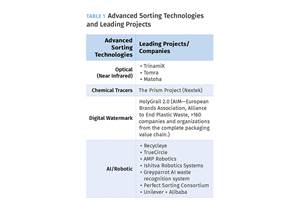

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More