Bioplastic Based on a Fragrant Cellulose By-Product

U.K. university researchers utilize chemical found in pine needles to produce new bioplastic.

U.K. university researchers utilize chemical found in pine needles to produce new bioplastic.

Last month, I blogged about strides being made in the development of novel biodegradable plastics, including one derived from the organic compound chitin extracted from shrimp shells and one based on the cassava root—both of which are targeted to the production of shopping bags, food packaging and other flexible film applications.

Strides are also being made in the development of renewably-sourced, tougher engineered bioplastics, and there’s a lot of attention on terpenes—a group of compounds synthetized in plants, particularly in coniferous trees such as pines.

In addition to being components of softwood and generated in large quantities as a wood waste product, other sources in nature include dandelions, rubber trees, and spices like aniseed, cloves, cinnamon and allspice.

Aside from being plentiful, the various terpenes—widely used for flavoring and fragrance—are becoming of particular interest to chemists as building blocks for more complex chemicals as replacements for petrochemicals. The reason is that they are chemically similar to molecules in crude oil: essentially, they are hydrocarbons in that they contain only hydrogen and carbon atoms.

This makes them easier and less expensive for chemists to work with, due to their familiarity with existing processes and equipment, compared to other plant-based materials, particularly those containing oxygen atoms.

Researchers from the Centre for Sustainable Chemical Technologies (CSCT) at U.K’s University of Bath have been working with pinene, a terpene found in pine needles. One aim has been to develop a biobased caprolactone, a rubbery component and key feedstock for nylon polymers.

A pinene-based caprolactone can replace its petrochemical counterpart when used with degradable polyesters such as PLA to make them more flexible and sustaining the ‘renewable’ aspect of the resulting plastic.

The research is still in its early stages—just a few grams have been produced, but the researchers are aiming to scale up the process within the near future. “This research is part of a wider project that looks at using biobased chemicals like pinene as a sustainable starting material for making a range of useful products in the place of petrochemicals. This reduces our reliance on fossil fuels and provides a renewable feedstock that has the potential to revolutionize the chemical industry,” said professor Matthew Davidson, director of the CSCT and Whorrod professor of Sustainable Chemical Technologies.

Funded by the Engineering and Physical Sciences Research Council, this project also entails the investigation of other terpenes, such as limonene from citrus fruit to make a range of products—from plastics to pharmaceuticals.

Just last year, I blogged about a process developed by the Fraunhofer Institute for Interfacial Engineering and Biotechnology (IGB) that has been shown to produce high-performance engineering plastics from terpenes. Results from this ongoing work and potential applications were featured by Fraunhofer at K 2016 this past October. These researchers first aim was to develop a nylon 6-like bioplastic. Their novel nylon, synthesized from the terpene 3-caren, is said to be significantly more transparent than nylon 6, making it suitable for new and high-quality applications, such as the production of ski goggles or visors of helmets.

Related Content

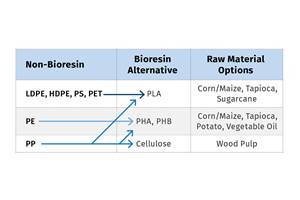

How to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreCJ Bio’s Amorphous PHA Demonstrates Excellent Biodegradability in Marine environment

The tests of the bioplastic, a semi-crystalline PHA and a PLA were conducted by the national Korean testing agency (KCL)

Read MoreWhy Are They Blending Biopolymers?

A sit-down with bioplastic producer Danimer Scientific showed me there are more possible answers to that question than I had previously thought.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)