Shale gas pushes petrochemical projects forward

Over a five-day period last week, two massive North America polyolefin projects made possible by shale gas marked significant milestones.

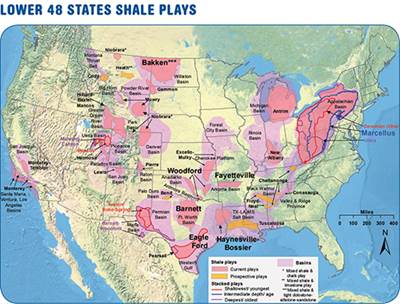

On June 13, the first barrels of ethane extracted during oil production at North Dakota’s Bakken Shale play were utilized by NOVA Chemicals at its Joffre, Alberta complex.

On June 17, Chevron Phillips Chemical hosted a groundbreaking for the polyethylene units at its U.S. Gulf Coast (USGC) Petrochemicals Project with polyethylene production slated for Baytown and Old Ocean, Texas.

NOVA is utilizing ethane derived from natural gas at Hess Corp.’s Tioga, North Dakota plant, which is transported into Alberta via the Vantage Pipeline. That pipeline has an initial design capacity of 40,000 barrels/day but is expandable to greater than 60,000 barrels/day.

“Ethane extracted from associated gas produced from Bakken Shale is expected to be a growing and stable feedstock supply source for the Alberta petrochemical industry.”

NOVA has already utilized natural gas from additional alternative outlets. In the first quarter, it applied ethane extracted from off-gas produced at Alberta oil sands, while Marcellus Shale basin based ethane became “a regular feedstock” at its Corunna, Ontario cracker, the company noted in first quarter earnings released on May 1.

In that statement, the company said it expects Joffre to be at nameplate capacity, north of 1 billion pounds, with plans to transition up to 100% natural gas liquids later this summer. At that time, the company reported a more than 30% increase in profits compared to the first quarter of 2013, citing increased operating profits and higher margins, specifically in its polyethylene segment.

"The introduction of Bakken Shale-based ethane into the feedstock diet at Joffre marks an important milestone in the diversification of our ethane sources for the region and our NOVA 2020 strategy to capitalize on North American demand,” stated Todd Karran, NOVA Chemicals Acting CEO and CFO.

On June 12, Chevron Phillips Chemical announced the successful commissioning and start-up of what it calls “the world’s largest” on-purpose 1-hexene plant. That unit has capacity for 250,000 m.t. (551 million lb).

Here too, the influence of shale was cited as real-live production begins:

"Our investment to expand 1-hexene production is due in part to Texas’ growth as a major international hub for the petrochemical industry and the increased supply of competitive feedstocks in the U.S. from the development of shale resources,” said Pete Cella, CEO of Chevron Phillips Chemical.

With shale-gas-sourced pellets entering, or soon to enter the market, the next question becomes: Will North American processors see a pricing benefit from feedstock-advantaged polyolefins, or will the cost benefts only go to producers bottom lines?

Chevron Phillips Chemical's projects by the numbers:

- Location: Cedar Bayou Chemical Complex in Baytown, Texas

- Annual Capacity: 250,000 m.t. (551,000,000 lb)

- Technology: third* plant to utilize Chevron Phillips Chemical’s proprietary selective on-purpose 1-hexene technology, which produces comonomer grade 1-hexene from ethylene.

*Qatar Chemical Company Ltd.’s (Q-Chem) facility in Mesaieed, Qatar, and Saudi Polymers Company plant in Al Jubail, Saudi Arabia are the other two.

Chevron Phillips, U.S. Gulf Coast (USGC) Petrochemicals Project

- Where: Cedar Bayou plant, Baytown, Texas, and Old Ocean, Texas

- What: 1.5 million m.t./year (3.3 billion lb/year) ethane cracker in Baytown, and two 500,000 m.t./year (1.1 billion lb/year) capacity polyethylene facilities in Old Ocean, Texas

Ed. Note: But wait, there's more!

This morning ExxonMobil Chemical announced the launch of its multi-billion dollar expansion of its Baytown, Texas operation. Per the company:

The steam cracker will have a capacity of up to 1.5 million tons per year and provide ethylene feedstock for downstream chemical processing, including processing at two new 650,000 tons per year high performance polyethylene lines at the company's Mont Belvieu plastics plant.

Read Next

Natural Gas Boom: What Will It Mean for Plastics Processors?

Plentiful shale gas promises to keep domestic polyolefin production costs among the lowest in the world. Whether (and when) you will see savings is debatable.

Read MoreThe Shale Gas Game Changer

Processors and resin suppliers alike believe the availability of low-cost feedstock will present huge opportunities in the North American plastics market.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More