Graphene Deemed a Highly Effective Antifouling Material

Researchers at two universities discover that laser-induced graphene zaps bacteria.

Scientists at Houston-based Rice University and Ben-Gurion University of the Negev (BGU) have discovered that laser-induced graphene (LIG) is a highly effective antifouling material, and when electrified, a bacteria zapper.

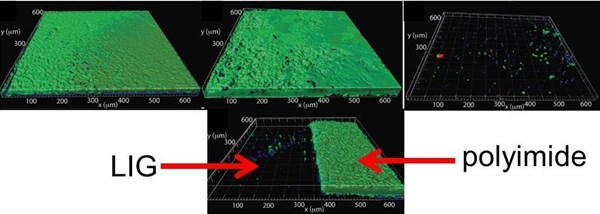

Rice University’s Jamed Tour developed LIG—a spongy version of graphene (the single-atom layer of carbon atoms)—three years ago by partially burning through an inexpensive polyimide sheet with a laser, which turned the surface into a lattice of interconnected graphene sheets.

Since then, the researchers have suggested uses for the material in wearable electronics, including smart watches/glasses, fitness trackers, and ankle bands, as well as for fuel cells and super hydrophobic or super hydrophillic surfaces.

In their report in the American Chemical Society’s ACS Applied Materials and Interfaces, the researchers note that LIG also protects surfaces from biofouling, the buildup of microorganisms, plants or other biological material on wet surfaces.

“This form of graphene is extremely resistant to biofilm formation, which has promise for places like water-treatment plants, oil-drilling operations, hospitals and ocean applications like underwater pipes that are sensitive to fouling,” Tour said.

He also added that the antibacterial qualities upon application of electricity are yet another benefit. When used as electrodes with a small applied voltage, LIG reportedly becomes the bacterial equivalent of a backyard bug zapper. Tests without the charge confirmed what has long been known—that graphene-based nanoparticles have antibacterial properties. When 1.1 to 2.5 volts were applied, the highly conductive LIG electrodes “greatly enhanced” those properties.

Under the microscope, as shown in the video, the researchers watched as fluorescently tagged Pseudomonas aeruginosa bacteria in a solution with LID electrodes above 1.1 volts were drawn toward the anode. Above 1.5 volts, the cells began to disappear and vanished completely within 30 seconds, At 2.5 volts, bacteria disappeared almost completely from the surface after one second.

The Rice researchers partnered with water-purification specialist Professor Christopher Arnusch, a lecturer at the BGU Zuckerberg Institute for Water Research. Arnusch’s lab tested LIG electrodes in a bacteria-laden solution with 10% secondary treated wastewater and found that after nine hours at 2.5 volts, 99.9% of the bacteria were killed and the electrodes strongly resisted biofilm formation.

There researchers suspect bacteria may meet their demise through a combination of contact with the rough surface of the LID, the electrical charge and toxicity from localized production of hydrogen peroxide. The contact may be something like a knee-hitting pavement, but in this case, the bacteria are all knee and the sharp graphene edges quickly destroy their membranes.

Fortunately, LIG’s antifouling properties keep dead bacteria from accumulating on the surface, Tour said. “The combinations of passive biofouling inhibition and active voltage-induced microbial removal will likely make this a highly sought-after material for inhibiting the growth of troublesome natural fouling that plagues many industries.”

This research was supported by the U.S.-Israel Binational Science Foundation, the Canadian associates of Ben-Gurion University of the Negev Quebec Region, the Israel Science Foundation, the Air Force Office of Scientific Research and its Multisdisciplinary University Research Institute.

In this real-time video, Pseudomonas aeruginosa bacteria tagged with green fluorescent protein, which appear as bright dots, are drawn to anode of laser-induced graphene, where they die. The anode at the top, which is separated from a cathode by a 100-micron channel, carries a small voltage that boosts its antibacterial properties.

Related Content

Surface-Activating Primer for Polyolefins and Fluoropolymers

XlynX Materials’ PlastiLynx is designed for use with low-surface-energy polymers for improved bonding and printing.

Read MoreGraphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Read MoreK 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More.png;maxWidth=970;quality=90)