Make Your Machine Time Count

At the end of the day, injection molders are ultimately only selling one thing: machine time.

At the end of the day, injection molders are ultimately only selling one thing: machine time.

Getting and keeping injection molding machines running, despite all the other services processors typically offer, often means the difference between boom or bust for molders. With that in mind, Plastics Technology has created an entire session at its Molding 2016 Conference & Exhibits (Westin New Orleans; March 29-31) devoted to ‘Establishing & Maintaining a Robust Process’.

Eight speakers from leading custom molders, machinery suppliers, OEMs, consultancies and plasticating component manufacturers will address how to create, maintain and repeat a robust molding process, replacing downtime and scrap with on-time deliveries and profits.

Joachim Kragl, director Advanced Injection Molding Systems & Processing at Engel, will walk attendees through the latest developments for the company’s iQ control package, including the most recent advances which allow the system to automatically adjust clamp pressure to compensate for viscosity changes in the material and create for consistent parts without tinkering with back pressure.

Robert Gattshall (author of this Plastics Technology article on scientific molding) will present on process development and establishing effective process limits, including defect and variation thresholds, while asking which process outputs should be monitored. In addition, Gattshall will speak to a problem shops with a mixed machine stable face: the lack of standards across machine manufacturers and machine-to-machine variation.

As important as melt temperature is to the molding process, its true measurement has remained illusive if not completely indiscernible. Two papers at Molding 2016 will directly address the “mystery of melt temperature.” Michael F. Durina, inventor and president Md Plastics Inc., will talk about the development of an inductive electromagnetic melt temperature sensor that is actually located with the machine barrel and nozzle. This new technology relays data on melt temperature, viscosity and equipment condition in real time.

In addition to Durina, Mark Berry of PPD Tech LLC and Yasuo Ishiwata, of Futaba Corp. of America will discuss use of a fiber-optic infrared sensor to measure true melt temperature. In addition, the paper will discuss how the technology can help find the ideal cooling time by measuring key parameters while the part is in the cavity.

Tessy Plastics Virginia, whose innovative integration of process and production monitoring for a paperless plant was highlighted in this Plastics Technology article, will also present at Molding. Doug Jobe, Tessy’s director of operations, will discuss how his company’s real-time process monitoring is helping it grow into Industry 4.0.

Scott Rogers, technical director of Noble Plastics, will present a paper entitled “The Value of Predictive Inspection.” Specifically, Rogers will share a method whereby dimensional inspection of molded parts can be predicted and how this method can be used to enhance mold design, part design, and production capability.

Suhas Kulkarni, author of this two-part series on how to optimize pack and hold times for hot-runner and valve-gated molds, will conclude the session with a discussion of Design of Experiments as a means to process simulation. Founder of consulting and training firm FIMMTECH and author of Robust Process Development and Scientific Molding, Kulkarni will discuss how out-of-spec parts can lead molders to change one parameter, without accounting for how that alteration can have knock-on effects with other specifications. His solution: A Design of Experiments simulation that’s done after actual data are collected and analyzed from a set of molder-led experiments. “Simulation is now based on actual data and not on initial flow simulations typically done at the part and mold design stage,” Kulkarni notes.

Register now and save for Molding 2016! Make the machine time you sell count.

Related Content

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreServo-Hydraulic Machine Range Adds Multicomponent Models

Absolute Haitian says the Mars and Jupiter Lines will now offer multicomponent models, complementing the 2K all-electric Zhafir.

Read MoreNew Multicomponent Injection Molding Machine Line Launches

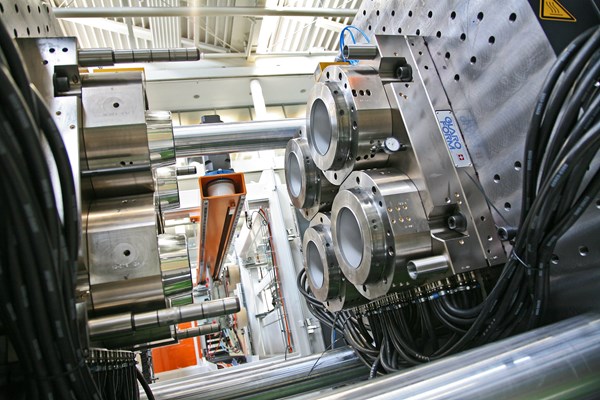

FCS Group’s X-Type parallel quartet injection molding machine features four injection units aligned in parallel for a smaller footprint.

Read MoreDual Injection Units on a Smaller, Electric Press for 2K Medical Molding

Engel extends its combi M dual-injection unit technology to a smaller tonnage machine with a horizontal indexing table for the first time at K 2022.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More