Startup Turns Recycled Plastic into 3D Printing Filament

Plenty of companies are taking advantage 3D printing’s disruptive nature in the manufacturing space, but I came across an Amsterdam-based startup that is taking the disruptive concept even further.

Plenty of companies are taking advantage 3D printing’s disruptive nature in the manufacturing space, but I came across an Amsterdam-based startup that is taking the disruptive concept even further.

Reflow converts recyclable plastic into 3D printing filament using open source technology. Reflow filament is made from recycled PET bottles collected in developing regions, and revenues from the filament go back to the waste collectors who gather these bottles, which the company claims can increase their income by up to 20 times.

Jasper Middendorp, Reflow CEO, visited recycling centers in Nairobi, Kenya last year and saw how the waste collection, trade and recycling systems work. He saw that waste collectors collect plastic all day and receive very little money for it. They may earn 10-15 cents per kilogram and, for many, that’s their family’s only income stream. Meanwhile, a kilogram of 3D print filament costs around $30.

“That’s a huge disparity, and the reason for the focus on plastic recycling and 3D printing,” he told Plastics Technology. “Reflow is looking to leverage the exponential growth in the 3D printing market to create value from the waste plastic being collected and to flow that value back into waste picker communities and local manufacturing in developing regions.”

The company has a big task ahead: it aims to turn the growth of 3D printing into income for more than 40 million waste collectors worldwide that collect waste for a living, earning less than $2 a day. But the company believes the impact it will have on these communities and on the environment is significant: every kg of filament sold results in the removal of 120 bottles from the streets and $3 additional income for waste collectors. The company’s aim is to sell 5000 kg of filament in the first three years. If they achieve this goal, waste collectors’ incomes will increase by $200,000 and 6 million plastic bottles will be removed from the street.

Currently, Reflow’s material comes from waste collectors in Dar es Salaam, Tanzania who pick plastic bottles by the road or at designated locations (bars, hotels etc.) and bring them to a satellite collection point or central facility. The plastic is weighed, examined and the waste collector is paid.

Reflow filament is suitable for all 3D FDM printers that are capable of printing in a range of 435°F-455°F, although a heated bed is recommended. Reflow filament can be used in any application where other ABS, PLA and PET filaments are used.

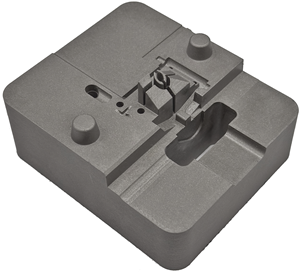

Reflow’s partner techfortrade, a UK-based charity, has developed an open source extruder that they set up at its partner location, STICLab in Dar es Salaam. The extruder can create 0.5 to 1 kg of filament per hour directly from plastic flakes. It was designed to fit the niche between the cheap home extruders that lack consistency for consumer production and the expensive industrial machines with high throughput. Middendorp said that they are in the process of improving on this second-generation extruder to a full production model over the next 6 to 9 months so that they will be able to fulfill purchase orders for the filament by the beginning of 2017.

Middendorp said that the company has some big technical and impact challenges in the coming months, but adds, “We are ready for them, and any others that come up.”

“On the technical side, there is work to be done with the extruder to make sure it reliably produces high quality filament. It’s very important for us to make a filament whose quality is as good as filament made from virgin plastic. We know no one wants to print with a sub-par filament, regardless of its ethical and sustainable elements,” he said. “We are also working on finding a reliable, continuous source of plastic, building relationships with waste collectors and tracking and tracing the money paid out to collectors in order to measure our impact.”

Related Content

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreBusiness Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreFreeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)