Don’t Forget the Cold Slug Well

Injection Molding Know How

Its primary function—as the name suggests—is to act as a trap, or “well,” for the cold slug.

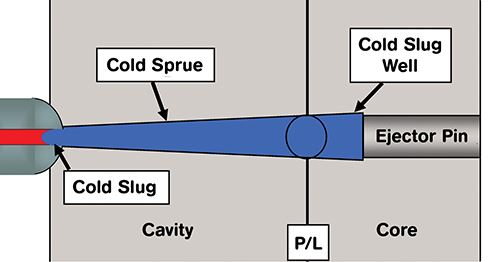

Many people think the fat end of a cold sprue is there simply to pull the sprue out of the sprue bushing when the mold opens. While it often is tasked to do that job, that’s not the cold slug well’s only function. Its primary function—as the name suggests—is to act as a trap, or “well,” for the cold slug. What’s the cold slug? It’s the small nub of plastic that cools and solidifies inside the nozzle tip during the cooling phase of the injection cycle.

This occurs because—while the nozzle is heated—the tip of the nozzle is pressed against the cold, water-cooled mold steel. The cold slug that forms at the nozzle tip is actually kind of handy in that it can act as a small plug to prevent drool during ejection. The problem is that during the next shot that little nub of cold plastic has to go somewhere, and you’d rather it not go into your part! Or just as bad, it can lodge in a subgate or pinpoint gate, partially blocking the flow.

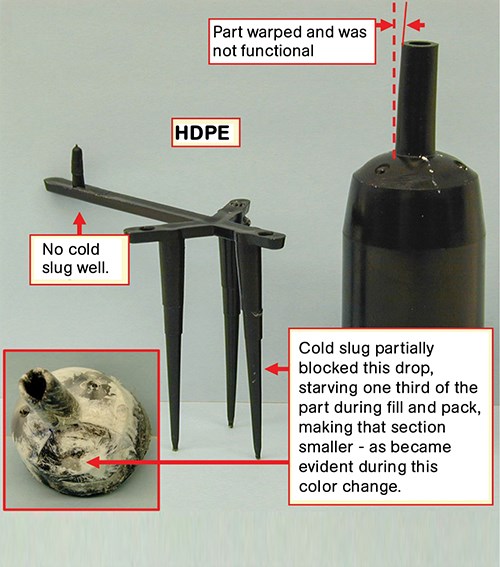

This is not an academic issue. See Fig. 2. The warped part and the runner system that caused it nearly derailed a multi-million-dollar product launch and caused much wailing and gnashing of teeth until the root cause of the problem was identified as a runner drop obstructed by a cold slug.

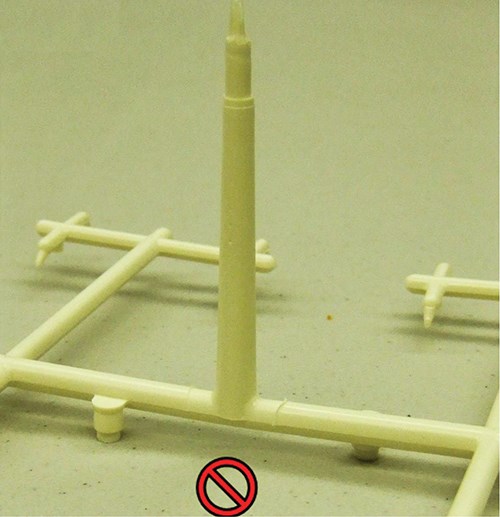

Fortunately, most moldmakers do put a cold slug well in the mold since, as mentioned previously, it’s useful for pulling the sprue out of the cavity when the mold opens. But many moldmakers must think that’s its only function, for when they use another method for pulling the sprue they often leave it out (Fig. 3). If you get a cold-runner mold in your shop and there’s no cold slug well, insist that one be put in. It’s generally a cheap and simple mold modification, and one that could save you a lot of headaches.

Related Content

-

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

PBT and PET Polyester: The Difference Crystallinity Makes

To properly understand the differences in performance between PET and PBT we need to compare apples to apples—the semi-crystalline forms of each polymer.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)