Screw Speed Versus Recovery Time

Many molders don't take screw-rotation speed into account when developing a process for a new mold. Here's why they should.

Developing a process for a new mold involves putting together a multitude of variables. Shot size, injection velocity, backpressure, and temperature settings are often near the top of the list. One that seems to be lower on the list—or at least does not get the attention it deserves—is screw-rotation speed.

Most people readily accept that screw rotation provides most (about 70–90%) of the energy needed to melt the plastic for the shot, so it is important. But little thought is often given as to what is best for a stable, repeatable cycle; and I regularly come across screw speeds (rpm) set higher than necessary.

To be clear, screw-rotation time cannot be set directly, as it is a result of several variables. But for process and cycle consistency, shot to shot, run to run, and machine to machine, the screw recovery time must be the same. Some argue that reproducing screw circumferential velocity is more important, and in theory this makes sense. Unfortunately my shop-floor experience indicates that better melt-temperature consistency is achieved by duplicating recovery time. Change screw-recovery time and you change the melt temperature and consistency. Duplicating recovery time seems to compensate for barrel/screw wear variations and different screw designs.

So what does influence screw-rotation time? The list is longer than expected:

1. Screw rpm.

2. Backpressure.

3. Cut of granules.

4. Size granules.

5. Size uniformity of granules.

6. Resin type and grade (it takes twice as much energy to melt most semi-crystalline resins vs. most amorphous resins).

7. Color.

8. Type of color carrier (liquid, solid, or powder).

9. Barrel-temperature profile, especially the rear zone.

10. Feed-throat temperature.

11. Barrel condition.

12. Screw design and condition.

To be fair, most of these process parameters have to be determined before screw rotation speed (rpm) and time can be addressed. Assuming the resin is specified, the process variables to be established before you can deal with screw rotation are shot size, backpressure, barrel-temperature profile, feed-throat temperature, stroke cutoff position, fill time, mold temperature, coolant flow rate per channel, cycle time, and second-stage (pack and hold) velocity, time, and pressure. To complicate matters, some of these influence what you are going to set for screw rotation speed.

Ideally screw rotate or plasticating time is not the determining factor for cycle time. That is, you are not waiting on the screw to build shot size before you can open the mold. Most cycle times are determined by the time needed to cool the part enough to withstand the force of ejection. That said, my guess is that about 20% of the industry’s cycles are determined by how fast you can get the screw back. We will deal with this condition later.

First we will deal with a cycle where the part needs more time to cool than it takes you to get the screw back to build the next shot. For example, take a part needing 12 sec of cooling time before the part is solidified enough to be ejected without distortion, sticking, pin push, or other typical problem with parts too hot to eject. In this scenario the screw currently takes 5.5 sec to build shot size with 700 psi backpressure (plastic, not hydraulic pressure), and there is 0.20 in. of decompression.

On most machines, decompression time is not included in the plasticating time, so you need to add on a fraction of a second to ccount for this function. Also check the consistency of the screw-rotation time during production. My bet is that recovery time varies significantly. In this case it could be more than a second. For cycle-time consistency, you do not want this variation of screw-rotate time to determine or influence your cycle.

Also, most agree that the lower the rpm, the better the melt uniformity. So set a screw-rotation speed that uses up most of the cooling time and provides an extra second or two to compensate for normal screw-recovery-time variation. In this case, you might need as much as 2 sec. So for the example above, slow the screw-rotation speed to provide a 10-sec recovery time. Do not adjust backpressure.

I am not saying you always need to provide 2 sec extra on cooling time to make up for screw-recovery variation. Look at production data and see how much your recovery time varies. You have to allow for this variance within your cooling time to keep the cycle time consistent. If your cycle is 6 sec, obviously you will be dealing in tenths of seconds for extra cooling time, and you still have to keep cycle time constant.

There is also the condition where the cycle is minutes long, and it is impossible to turn the screw so slowly to take up all the cooling time for recovery. In this case, take as much time as you can to get the screw back and use screw-start rotation delay in combination with cooling time to provide consistent cycles. Once again, this is a thermal process, so cycle time must be consistent.

Now let’s tackle the other 20% of the cycles where cooling time is too short to allow screw rotation to charge the next shot. In this situation the parts are cool enough for ejection but the screw is still turning and melting plastic for the next shot, so you cannot open the mold. First, add on a nozzle shutoff valve to allow for screw rotation during mold opening and closing. There are often seconds to gain by doing this, but the flip side is additional maintenance. Shutoff valves are high-wear components.

If you are using liquid color, turn off the color for a few shots and see if screw recovery time shortens. If it does, someone has to have a sit-down with management. Crunch the numbers and they will show that more expensive solid color is cheaper when the machine time is factored into the equation. Also, experimenting with the rear and feed zone temperatures can gain faster recovery times.

ABOUT THE AUTHOR

John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. E-mail john@scientificmolding.com or visit scientificmolding.com.

Related Content

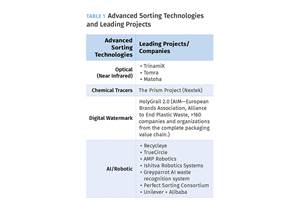

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More.jpg;width=70;height=70;mode=crop)