Vacuum Pumps

The heart of any central conveying system is the vacuum pump(s). There may be one pump or several pumps. They create the vacuum that pulls the material from the source to the destination.

There are often several pumps required and they need to be sized properly to ensure sufficient airflow.

Each pump should be connected to an efficient cyclone that removes 99% of the dust and fines from the airflow, before it gets back to the pump filter.

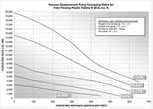

Vacuum pumps are sized based on “Equivalent Feet of Airflow” (see below), the line diameter and the conveying rate.

For information on the types of pumps – see Vacuum Pumps

In general:

Regenerative Blower Pumps are the least efficient and are suitable for low to moderate throughputs and/or short-moderate conveying distances.

Positive Displacement Pumps moderately efficient and are are designed for moderate-high throughputs and longer conveying distances.

Ultra High Vacuum Pumps are the most efficient and best suited for high throughputs over long distances.

Each type of pump has it’s own niche.

Basic principles for sizing vacuum pumps.

Minimize the number of elbows, vertical lifts, and length of flexible hose.

Avoid up-slopes in material lines.

Avoid multiple bends after exiting a take-off box.

Do not undersize pumps…they will work harder and increase energy costs.

*Size pumps properly, according to these rules:

- 1 horizontal ft of tubing = 1 equivalent ft.

- 1 vertical ft of tubing = 2 equivalent ft.

- One 90 degree elbow = 20 equivalent ft.

- 1 ft of flex hose = 3 equivalent ft.

- Remember to consider obstacles that stand in the way of conveying and air lines – such as HVAC ducts, walls, etc.

- An average railcar is 66 ft long.

Pump Curves

There are “Pump Curves” for each size of each type of pump. The equivalent feet and required conveying rate in lb./hr. are compared to the pump curves to determine the pump size required.

TIP Keep pump filters clean and empty cyclone dust collector pan to maximize pump

efficiency.

TIP Line plugging and shorter pump life will be the result if you undersize pumps.