A membrane dryer is a type of compressed air dryer that uses a membrane to remove moisture and other contaminants from the air. The membrane is typically made of a polymer material, such as polyamide or polyurethane, and works by separating the water vapor and other contaminants from the compressed air.

The operation of a membrane dryer involves passing the compressed air through the membrane, which has a series of tiny pores. The pores allow the air to pass through while trapping the water vapor and other contaminants, which are then vented out of the system.

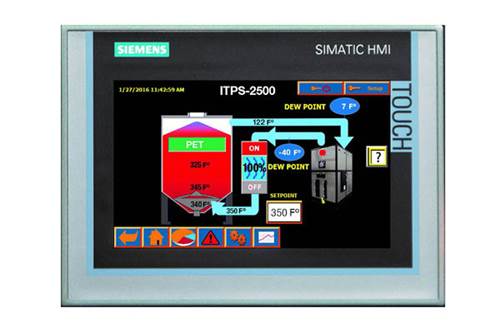

These dryers are commonly referred to as compressed air/membrane or membrane/compressed air dryers but the keyword is membrane. There is a big difference between a "compressed air dryer" and a compressed air dryer with a membrane. A compressed air dryer does not produce -40 dew point process air (it's more like 0-20 dew point) and can vary week-to-week and season to season.

A membrane improves the compressed air dryer by ensuring -40 dew point process air so the drying capability of a membrane dryer is much better than a conventional compressed air dryer.

There is also a big difference between a membrane dryer with a built-in membrane as compared to one with an add-on membrane. Those with add-on membranes - use up to three times as much energy as as those with built-in membranes.