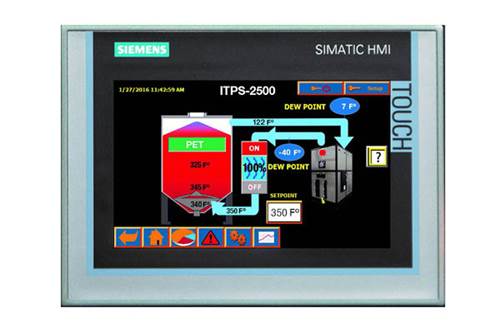

Today, most new PET drying systems sold are based on using a desiccant wheel dryer. There is no doubt that the wheel dryer provides significant energy, space and maintenance savings over a system using a conventional dual bed desiccant dryer and PET processors recognize the advantages of wheel dryers.

Key components of a PET Desiccant Wheel Drying system:

- Desiccant wheel dryer

- Multi-zone drying hopper

- Electric or optional gas-fired process heater

- Cyclone

- Self-cleaning "pulse"-type dust collector

The components listed above are all that are really needed for drying PET. Controls now have automatic energy-saving features providing better efficiency. These systems also offer lower initial costs and reduced lifetime maintenance. In this system, patented features automatically adjust the drying hopper outlet temperature as well as the blower and desiccant wheel speed to save energy and ensure process consistency.

The advantage of using a gas-fired process heater depends entirely on the electric cost per kWh for the processor and the size of the dryer. The larger the dryer throughput - the greater the savings. PET processors with throughputs of 2500 lb./hr., or more, per line, stand to gain the most. If the price of electricity is $.07/kWh, savings are noticeable but if the price is closer to $.10/kWh (the national average) savings can be outstanding - with an ROI of 10-18 months, depending on the dryer throughput.

Energy Rebates have become quite popular in recent years. Depending on where your plant is located, there may be county, state, federal, or energy company rebates available to greatly offset the cost of new, energy-saving equipment. Some dryer manufacturers are prepared to help you find the source of these rebates and help provide the energy-saving documentation required to capitalize on the rebate programs.