Machine Mounted Mixers

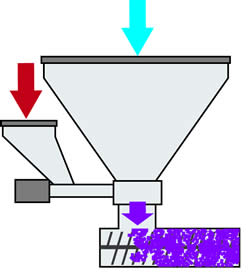

Dosing or additive feeding devices typically do not include a suitable method of actually blending the mixture of ingredients. They rely on the mixing action of the processing machine screw to assure homogeneity of all the materials being joined. So a popular option to ensure a suitable mix is a machine mounted mixer to tumble the ingredients prior to entry into the processing machine.

These throat-mounted devices are very similar to the mixing chambers incorporated into automatic blenders, but operate independently to tumble materials together as they pass through to the process.

Available in a range of sizes to accommodate not only processing thru-put but also the scale of the equipment mounted to them, better models incorporate features for performance, strength, safety and convenience.

Features include:

- Stainless steel material contact surfaces

- Baffle plate(s) to create a void for the introduction of additives and to reduce ‘head pressure’ above the processing screw.

- Engineered blade and mixing chamber design for maximum material movement, superior blending performance and minimal strain on the mixing motor.

- Easy cleanout with easy access door(s) and easily removed components, complete with safety interlocks.

- Visibility, via viewing window(s)

- Large, strong mounting plates on top and bottom for ease of installation and use with a wide range of equipment.

Machine mounted mixers are a must for older processing machines with unsatisfactory mixing action in their screws. Selection of the proper machine mixer ensures a homogenous blend and coloring is more efficient, more thorough and more uniform. Color consistency of the finished product is improved and problems such as streaking are virtually eliminated.