Why Blend?

Every processor has a choice in how to feed material to their process in order to produce saleable product with the characteristics they require.

In the past, most processors purchased materials that were pre-compounded into specialized pellets to produce the specific color and properties that they needed. It was a very simple process then, to simply feed these customized compounds into their process. However, the cost of these custom compounds were significantly higher than the cost of the individual raw ingredients.

In addition, cost-conscious processors knew they needed to deal effectively with the regrind that was produced from their process and understood that simply discarding it or selling it to others for re-processing cost them money. They could very easily roll it back into their own process if they had a method for introducing it into the material stream at a repeatable, measured rate.

In addition, since many processors changed the material, the color and the characteristics of the products they produced, keeping quantities of all the uniquely compounded materials they processed created an inventory nightmare.

The solution? Blending and Dosing.

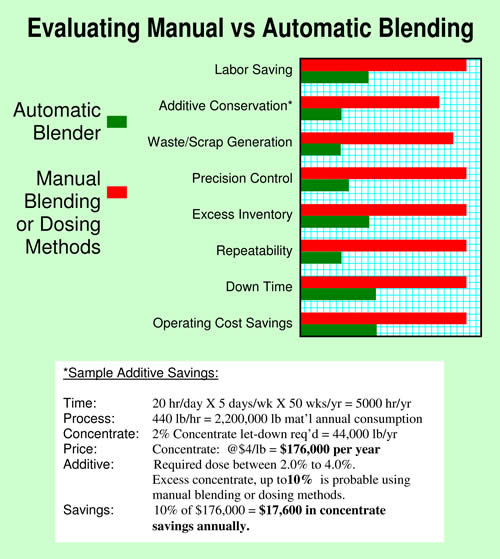

By using a precision device for mixing materials together, as needed, inventories are reduced to only the necessary raw materials for the process, there is no costly pre-compounding step and reground material can be rolled directly into the process as required, with no disruption in the process flow. This results in significantly lower material costs, less inventory of materials, more efficient usage of reground material and, if the correct blending/dosing device is utilized, an increase in part or product quality and 100% repeatable results.