Single-Wall Carbon Nanotubes Stay Put

OCSiAI’s test results with HDPE, epoxy, and elastomers show no release of particles when materials are mechanically stressed.

Back in 2007, I reported on carbon nanotubes and other electically-conductive and/or thermally-conductive nano-particles noting that there is plenty of potential, if the price is right. Hampering their progress was high cost and miniscule supply, but even then, these limitations were on their way to being resolved.

In the intervening years, however, concerns have arisen regarding the release of these particles from nano-reinforced plastics products and their potential health and safety hazards.

A recent study by Luxembourg's OCSiAI (U.S. office in Columbus, Ohio), the world’s largest manufacturer of single-wall carbon nanotubes, showed impressive results with the company’s Tuball single-wall carbon nanotubes that were unachievable with conventional additives and other nano-additives.

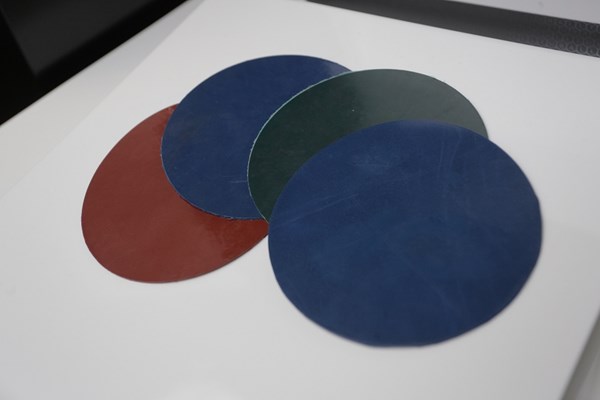

Pictured: Colored conductive HDPE and PVC with 0.1% by wt. Tuball nanotubes.

End-users and high-tech manufacturers of products that use nano- and micro-sized carbon additives such as multi-wall carbon nanotubes and carbon fiber have been concerned for some time about the release of particles during damage to the material. OCSiAI initiated health and safety testing on migration of its single-wall carbon nanotubes from a material’s matrix.

The work was conducted by VITO, a leading European independent research and technology organization. Simulation experiments were conducted on non-reinfoced and Tuball nano-reinforced materials. These were carried out inside a test chamber and any possible aerosol release was captured and measured with a TEM microscope. Carrier resins used include HDPE, epoxy and elastomers.

Pictured: Antistatic mining signal light body made of ABS with 0.3% by wt. Tuball nanotubes.

The TEM analysis revealed a remarkable outcome, according to the researchers: in the drilling and Taber abrading tests, in contrast to the other additives, no protruding particles appear and no free-standing particles are released when materials containing the Tuball nanotubes are mechanically stressed during simulation of their typical use.

Another finding was that the number of nano-sized particles released from the Tuball-reinforced materials compared to the others decreased by up to 35%, depending on the material. The researchers noted that this is yet another demonstration of the bonding power of single-wall nanotubes that enables a 3D nanotube network to greatly strengthen the material’s structure. This exciting enhancement of a material’s physical properties is the subject of ongoing research and includes several other thermoplastics.

OCSiAI’s is investing in health-safety research projects conducted by independent universities and research institutes, and it is an associate partner of the new EC4SafeNano project (EU’s Horizon 2020 research and innovation program), which aims to ensure the sustainable production and use of nanotechnology.

Meanwhile, though most of the work with single-wall carbon nanotubes initially entailed thermosets like epoxy and vinyl esters, and some high-end engineering resins like nylons, PEEK and PEI, Tuball single-wall nanotubes have been making headway in commodity thermoplastics.

Pictured: Colored and permanently antistatic HDPE tanks produced with Tuball by rotational molding.

Related Content

-

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

-

Resin Prices Still Dropping

This downward trajectory is expected to continue, primarily due to slowed demand, lower feedstock costs and adequate-to-ample supplies.

-

Improving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.