AUXILIARY EQUIPMENT: System-Wide PLC Control of AuxilIaries

New control system priced below older technologies.

Novatec, Baltimore, has introduced an FX2 NovaNet version of their original FlexXpand control that provides access and control of all Novatec auxiliary equipment through either 7-in. or 12-in. high-resolution color touch screen PLCs, and is also remotely accessible with a networked smart device or PC.

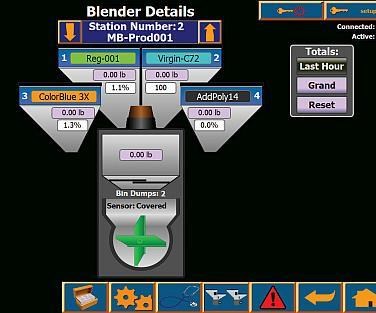

This new FX2 NovaNet provides control of up to 160 Novatec receivers, 20 vacuum pumps, and offers many options such as source-to-destination ID proofing. In addition, it provides access to other Novatec– supplied equipment, including up to 4 central dryers with up to 48 central drying hoppers (photo top), up to 12 silos with a choice of level sensors, silo fill ID proofing, railcar unloader units, and up to 32 WSB blenders (photo bottom). Other networkable products include NovaWheel Dry/Convey units, as well as downstream extrusion equipment like the company's cutters, pullers and up-cut travelling saws.

Every FlexXpand control can be accessed via web browser by any networked computer, or via VCN App by a networked Smartphone or Tablet. Actual FlexXpand screens are displayed remotely, and changes can be made easily with a simple click.

Processors can start using the FX2 NovaNet Control System on a small scale and expand it as they grow without any extra programming. Novatec has done all the programming of standard Siemens PLCs, and these well thought-out packages have been designed to minimize the confusion and high cost associated with older networkable controls, and maximize the ease-of-use.

Related Content

-

Wisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

-

Mobile Sanitary IBC Unloading and Conveying System

Transfers contamination-sensitive bulk solid materials from IBCs to downstream processes, dust-free.

-

Conveyor Controller Ideal for Expanding Plants

Billed as the most flexible and reliable discrete wired conveying controller on the market.