Engel Hosts Tech Symposium, Updates Global Expansion News

At a packaging and medical themed technology symposium at its technical center in California, the Austrian maker of molding machines and automation discussed global investments in its business.

Over two days, Austrian injection molding and automation supplier Engel Machinery, Inc. (North American headquarters in York, Penn.) invited customers, vendor partners and trade press to its recently remodeled technical center in Corona, Calif. Markus Lettau, regional sales manager for Engel North America, acted as emcee for symposium, which had a medical theme the first day and a packaging focus on the second, offering presentations covering trends from a market and technology viewpoint.

In addition to presentations, Engel had two cells operating at the event (which also ran at the company’s K 2016 stand):

An all-electric e-motion 220 (240 tons) WP (wide platen), running a spinning stack cube mold from Foboha in an injection blow molding process collaborated on with Alpla Werke Alwin Lehner to create small containers.

An all-electric e-motion 110-ton molding interdental brushes from an 8-cavity Hack Fomenbau tool, with modular cells from automation supplier Hekuma handling takeout, inspection and packaging.

Coming off a 2015-2016 fiscal year when it generated Euro 1.25 billion ($1.34 billion) in revenue, the company is reinvesting in its operations all around the world in small ways—the Corona technical center was remodeled, adding a classroom and reconfiguring the entry space—and large—company headquarters in Austria are wrapping up a multiyear project. In total, the company will be investing Euro 100 million ($108 million) over 2016 and 2017 across its facilities globally.

New Space for Sales/Service, Apprentices and Toddlers

In his presentation, Lettau referenced the nearly completed 33,000-ft2 addition to Engel’s headquarters in Schwertberg, Austria. Started in the summer of 2015, an Engel spokesperson said the addition is nearly completed. As built, it includes nearly 20,000-ft2 of sales and service offices; a 4265-ft2 apprentice workshop; as well as an additional on-site daycare for the children of Engel employees, which will have a literal “kindergarden” of sorts via a vegetable garden for the nursery. “The toddlers will grow their own vegetables soon,” the spokesperson noted.

Down the road, the spokesperson said Engel will further expand assembly capacity in Schwertberg, enlarging the Northern production hall which was built in 2013, as well as adding a new customer technology center.

More Spare Parts, Faster from York

In the U.S., Engel is planning an investment of $1 million into its spare parts facility in York. The process and space will be modernized with the latest technology, according to Engel, with an additional $10 million to be spent on spare parts inventory. That project will start in the fall of 2017. Lettau noted that Engel has more than 70 networked logistics center globally and invests Euro 85 million ($91.5 million) in spare parts annually, with the ability to deliver most parts with 24 hours, 72 hours maximum.

An Engel spokesperson said the company will also be looking at its automation operations in North America, with planning underway to reduce delivery times for robotics customers in North America.

Engel is planning a similar event April 26 and 27th at its York, Penn. Headquarters, with medical on the first day, packaging on the second, as well as a partner fair and live machine and automation exhibits.

Related Content

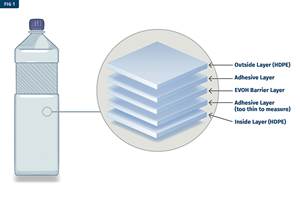

Measuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreIn Sustainable Packaging, the Word is ‘Monomaterial’

In both flexible and rigid packaging, the trend is to replace multimaterial laminates, coextrusions and “composites” with single-material structures, usually based on PE or PP. Nonpackaging applications are following suit.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More