A new, patent-pending traveling planetary cutter (M-TPC) from

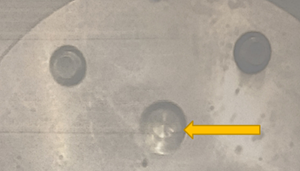

Conair, Cranberry Township, Pa., features a fully-programmable, servo-driven cutting head that reportedly cuts small-diameter medical tubing so precisely that the need for secondary, off-line tube finishing is virtually eliminated. The planetary knife spins around the circumference of tubing from 0.080 to 1 in. OD, cutting it without deformation, particulates, burning or fracturing.

Unlike other cutters that remove tube material and can leave particulates behind, the M-TPC planetary cutter actually splits the tubing apart cleanly through displacement, without the loss of any material. This cutting method never blocks continuous airflow through the center of the tube, so tube sizing and ovality are not affected as they can be when flying-knife cutters are used. The programmable, servo-driven cutting head enables complete and precise control of cutter speed (surface speed), rate of cutter penetration (feed speed), and final depth of the cut.

“Most rigid medical tubing today is cut-to-length using rotary or fly-knife cutters,” explains Bob Bessemer, Conair's Medical Downstream Extrusion sales manager, “and the results have been mixed. Even with close-fitting cutter bushings and good blade technology, it is sometimes difficult to obtain a square, distortion-free/particulate-free cut on the extrusion line. When a rotary knife impacts a rigid tube, the tube is slightly flattened until the blade actually penetrates the tubing and this can affect ovality and edge squareness at the cut site. There are other undesirable effects, too, including scratching, angel hair or agglomeration. Depending on the fit and function required for the application, these flaws may be unacceptable. In that case, tubing needs to be cut oversized on-line and then re-cut off-line, by hand, to finish the part.”

The planetary cutter is mounted on a precision, servo-driven traveling table that can handle tubing automatically at line speeds of up to 100 ft/min. The cutter’s standard servo controls enable it to make distortion-free and particulate-free cuts at rates up to 45/min while holding cut-to-length tolerances of ±0.031 in., even on shorter lengths of tubing. The cutter can be used with the full range of medical plastic tubing, including difficult-to-cut materials such as styrene, PET, HIPS, and PC.

The M-TPC cutter features a front-mounted touchscreen control that enables an operator to set table travel velocity, tubing size, blade velocity, and cutting depth. Once created, specific cutting programs or ‘recipes’ can be stored in on-board memory for easy recall and re-use. The cutter is engineered to allow for quick blade changes without the need to remove product from the machine, so the need to stop and restart the line for blade replacement is eliminated.

“The Conair M-TPC cutter was developed to eliminate the need for secondary cutting and finishing in the production of precision medical tubing,” Bessemer adds. “Given the added level of blade control, and the ability to lubricate the cut using alcohol, the M-TPC cutter makes it possible to achieve an almost perfect cut.

For applications that require even tighter cut-to-length tolerances than those provided by the standard servo-controlled cutter, the M-TPC can be fitted with an optional dead stop that maintains cut-to-length tolerances of ±0.005 in. or less. A switch initiates the cut cycle, starting table travel and clamping the tube so it comes to rest gently against the physical stop before being cut precisely.