Vinyl Alcohol Polymers Are Moldable and Extrudable

Two companies claim to have achieved a long-sought goal by launching vinyl alcohol-based thermoplastics that are injection moldable and extrudable while retaining the water solubility and biodegradability of polyvinyl alcohol (PVOH). One of the new products is a PVOH compound; the other is a new vinyl alcohol copolymer.

Two companies claim to have achieved a long-sought goal by launching vinyl alcohol-based thermoplastics that are injection moldable and extrudable while retaining the water solubility and biodegradability of polyvinyl alcohol (PVOH). One of the new products is a PVOH compound; the other is a new vinyl alcohol copolymer. There have been a number of attempts in the past to overcome the fact that PVOH thermally degrades at a temperature very close to its melting point. Although a small number of firms have developed proprietary methods of melt extruding PVOH films, most water-soluble PVOH films are cast from a solution. Vinyl alcohol has been made melt processable by copolymerization with ethylene in EVOH, but the result is not water soluble nor biodegradable. MonoSol LLC, Merrillville, Ind., a supplier of PVOH films, has now come out with injection moldable MonoPol PVOH compounds in four grades. Three semi-crystalline grades are soluble in cold water (down to about 50 F) and one in hot water (above 158 F). Available in colors, they are aimed at containers (pictured), soluble cores for lost-core molding, andsingle-use medical applications such as handles for surgical instruments that can be initially sterilized with radiation and then dissolved after use during steam sterilization of the metallic part of the instrument. These compounds are fully biodegradable in water solution. MonoPol has a density of 1.28 g/cc and commercial cost is estimated to be less than $5/lb. It has a melting point from 365 to 410 F and around a 36° F window of melt temperature before it degrades, turning yellow and crosslinking, which reduces water solubility. Tensile strength is in the range of 4400 to 5300 psi, elongation at break is 140 to 200%, flexural modulus is 20,000 to 58,000 psi, notched Izod impact strength is 4.4 to 25.5 ft-lb/in., and Vicat softening point is 241 to 343 F. MonoSol is conducting trials with MonoPol in sheet extrusion and coextrusion blow molding. The resin has been characterized for Moldflow injection molding simulation. Meanwhile, a new extrudable vinyl alcohol copolymer is being sold as a high-barrier coextrusion resin that is cold-water soluble and biodegradable/compostable in both solution and solid form. Nichigo G-Polymer comes from Nippon Gohsei of Japan and is available here from Soarus LLC, Arlington Heights, Ill. (Both firms also supply Soaranol EVOH.) Developmental Nichigo G-Polymer is highly amorphous but has 200 times the oxygen barrier of semicrystalline EVOH under dry conditions. It is aimed at monolayer and multilayer barrier films, one possibility being all-biodegradable films based on polylactide (PLA). Nichigo G-Polymer is said to have good transparency and is suitable for oriented and shrink films. It can also be injection molded. Its extremely high hydrogen barrier suggests potential use in fuel cells. The resin has a melting point of 284 to 374 F and decomposition temperature of 741 F, leaving a broad processing window. Nippon Gohsei has about 5 million lb of capacity for the resin. Estimated price is $7 to $9/lb, though the company is working on lower-cost grades as well as specialty grades with tailored amorphous content, melting point, and molecular weight. (219) 762-3165 • www.monosol.com (847) 255-1211 • www.g-polymer.com

Soarus, LLC

3930 Ventura Dr. Arlington Heights, IL 60004

Phone (847) 255-1211 Fax (847) 255-4343

Related Content

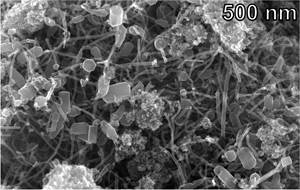

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More