CAE Services Corporation

-2013-reflection.png;maxWidth=200)

280 Belleview Ln.

Batavia, IL 60510 US

630-761-9898

caeservices.com

About CAE Services Corporation

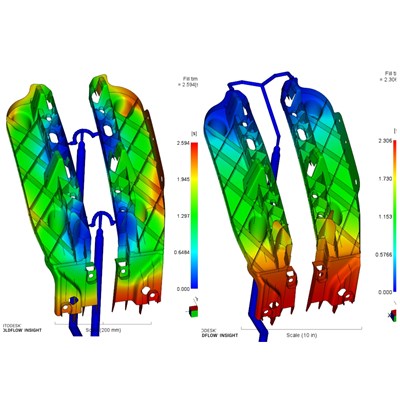

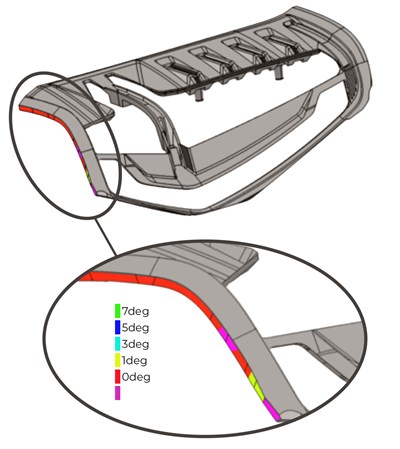

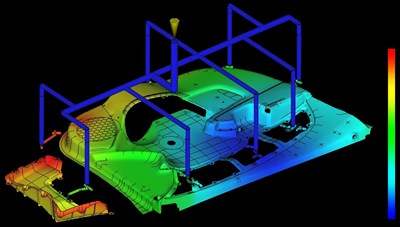

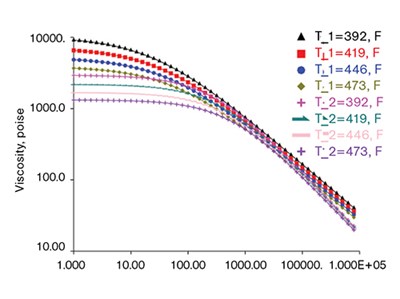

With the largest Expert Moldflow analysis team in the world we specialize in solving molding problems.