Jomar Corp.

115 E Parkway Drive

Offshore Commercial Park

Egg Harbor Township, NJ 08234 US

609-646-8000

jomarcorp.com

About Jomar Corp.

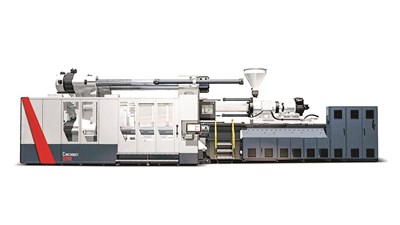

Jomar manufactures injection blow molding machinery from 25 tons to 175 tons. Jomar engineering services can design products and molds, including turnkey systems. Jomar is also the exclusive North American distributor of Automa by Magic extrusion blow molding machines, including hybrids.

IS THIS YOUR COMPANY?

Video Gallery

AE20PC

The AE 20 PC is an extrusion blow molding (EBM) machine from Automa by Magic distributed exclusively in North America by ...

991615001 AE25

The AE 25 S is a 28 ton Automa by Magic extrusion blow molding (EBM) machine distributed exclusively in North America by ...

40 cavity mold running on Jomar Model 175

Video of a Jomar Model 175 servo-hydraulic machine running 40 cavities of a 10ml vial at a cycle time of under 14 seconds.