PCS Company

34500 Doreka Dr.

Fraser, MI 48026 US

800-521-0546 | 586-294-7780

pcs-company.com

About PCS Company

PCS Company is a team of industry experts providing solutions and innovative products for the plastic injection molding, mold making, and die casting industries.

IS THIS YOUR COMPANY?

Video Gallery

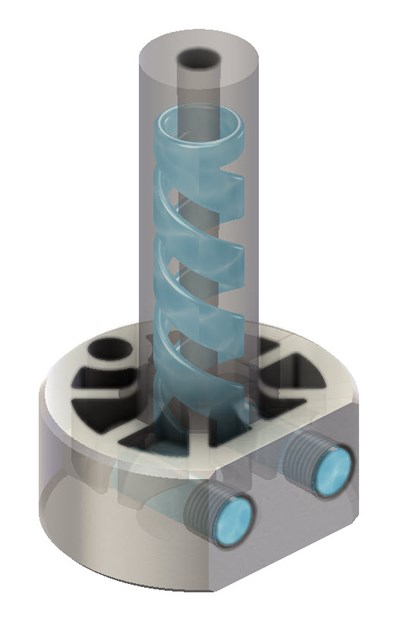

pcs smartflow configurator demo1

This video shows how to use the Smartflow® Manifold Builders found on the PCS Company website to configure water manifolds, ...

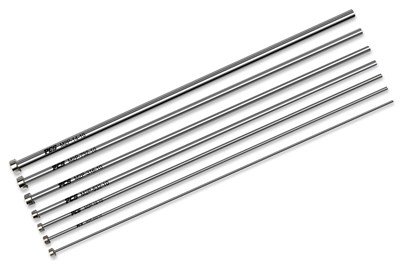

PCS barb tech v1 Original

PCS Company offers the Barb-Tech™ PQD hose assembly tool kit to address the assembly of Socket Connectors Non-Valved or ...

PCS gesswein U6 welder v1 Original

PCS Company offers the Gesswein Mold & Die Micro TIG Welder U6 - 110V for repairing parting lines, mold seams, 3-point ...

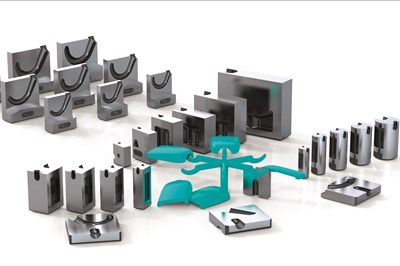

PCS slide latch assembly v1 Original

PCS Company Slide Latch Assemblies are designed to provide slide retention within the mold base. Three sizes are available, ...