Trexel Inc.

100 Research Dr.

Wilmington, MA 01887 US

800-733-2946 | 781-932-0202

trexel.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Trexel Inc. Supplies the Following Products

- Blowing Agents--Chemical Type

- Blowing Agents--Concentrates

- Blowing Agents--Physical Type

- Consultants - Design, Manufacturing, Purchasing

- Gas & Water Injection Systems

- Metering, Proportioning Equipment

Trade Names Offered by Trexel Inc.

Editorial, News, and Products

-

Compounding and Injection Molding Combined in Circularity Display

NPE2024: KraussMaffei aims to “make plastic green” with in-booth moldings and recycled plastics converted into other applications through a combination of injection molding, extrusion and inline compounding.

-

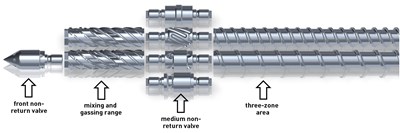

Microcellular Foaming Paired With Specialized Screw, Process Control Program

KraussMaffei will apply its APCplus dynamic process control technology and an optimized screw with the MuCell process in Friedrichshafen.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

Modular Screw Optimized for Microcellular Foam Molding

KraussMaffei says its HPS-Physical Foaming screw features a universal design and 30% higher plasticizing capacity for MuCell molding.

-

Trexel & W. Müller Team Up on Multilayer Foam Blow Molding

MuCell technology gains new momentum in blow molded packaging through this partnership of a leader in physical foaming with supercritical gases and a leader in coex blow molding hardware and controls.

-

Trexel Announces New CEO

Levi Kishbaugh, who has been at Trexel since 1999 and most recently served as VP of Engineering at the company, replaces fomer CEO Brian Bechard who passed away suddenly last August.

-

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

-

Bockatech Pushes New Boundaries at K 2022

Three years after debuting at K 2019, Bockatech’s EcoCore technology is boasting faster cycle times and lighter containers with greater properties as it targets more verticals and broader brandowner adoption.

-

Mold Opaque White PET Bottles – Without Pigment

Trexel and Husky are cooperating on molding recyclable opaque white preforms for PET bottles, which provide a light barrier using foam instead of pigment.

-

Renewably Sourced, Foam-Core PP Bottle on Display at K 2022

Borealis Renewables PP bottle uses MuCell foaming technology in its core layer.

-

New Micro-Foam Solutions for Bottles

Trexel is offering hardware to enable use of microcellular foams in blow molded packaging with complex shapes, handles and PCR content, while retaining impact strength.

-

Trexel President and CEO Brian Bechard Passes Away

CEO of Trexel since 2015, Bechard, 48, suffered a heart attack while competing in a rowing race.

-

Trexel Broadens Support for Foam Blow Molding

Agreement with MuCell Extrusion allows Trexel to pursue foam blow molding in packaging as well as automotive.

-

Foam PP to Improve Sustainability and Cost

Cost-effective use of PP is a major consideration, but the biggest driver of PP foaming is pursuit of sustainability.

-

Booster Unit Amplifies Microcellular Foaming

Trexel’s NC-Series Nitrogen Booster can reliably supply nitrogen supercritical fluid (SCF) to multiple satellite dosing units, creating a low-cost option to equip multiple molding machines with MuCell microcellular foaming.

-

Trexel Names New Head of Business Development

Foaming leader names Kaufmann director of business development. Announces retirement of long—time exec Traut.

-

Engel Announces Virtual Structural Foam Molding Conference

Free, three-day foammelt conference shifts to a virtual format, providing info on all aspects of structural foam molding.

-

Penn State Behrend Installs Consigned Zeres Injection Molding Machine

The university’s plastics processing lab will use the electric 101-ton Zhafir Zeres injection molding machine in hands-on coursework as part of its B.S. in Plastics Engineering Technology.

-

Trexel hires Ludwig to Lead Packaging Sales

Joins foaming specialist after 35 years working for both processors and equipment suppliers.

-

Blow Molding: Something for Everyone at K Show

Packaging, industrial, continuous-extrusion, accumulator-head, injection-blow, stretch-blow, EPET, foam, sandwich co-injection—the blow molding news was wide ranging at K 2019.

-

K 2019 Preview: Injection Molding Goes for the ‘Green’

‘Circular Economy’ joins Industry 4.0 as common themes of injection molding exhibits in Düsseldorf.

-

Injection Molding: Now Mold Microcellular Foams with a Standard Screw & Barrel

Trexel’s new Tip Dosing Module cuts cost and boosts performance by eliminating the special screw and barrel for MuCell foaming.

-

Can Foam Add Fizz to Your Molding Profits?

New improvements to Trexel’s MuCell foam injection molding process add fast-cycle capabilities, novel inspection technology, and lower upfront investment.

-

Headlines from Fakuma 2018

Integrating a special low-pressure process into machine controls; novel shop-floor quality-inspection technology; MES systems from machine and controls vendors; and sophisticated in-mold decorating.

-

Non-Destructive, Non-Hazardous Approach to Rapid Internal Inspection of Molded Parts

Terahertz spectroscopy allows in-line or off-line inspection of not only dimensions such as wall thickness, but also internal structure of solid or foamed parts.

-

NPE Wrap-Up: News in Primary Machinery, Part 1

Rounding up details from the Big Show not previously reported in all our other coverage, here’s more news in injection and blow molding, extrusion and compounding. Next month, we’ll conclude with recycling/scrap reclaim, robots, tooling, auxiliary equipment, materials and additives.

-

NPE2018 New Technology Focus: Foam Fascination

A new physical foaming process and a significant enhancement of the MuCell process attract attention at the show.

-

NPE2018 New Technology Focus: Do It in the Mold

In-mold labeling and decorating are applied to packaging and automotive parts at numerous booths throughout the show.

-

New Foaming Technology for Thin-Wall Parts

Trexel’s new MuCell P-Series nitrogen dosing equipment enables greater lightweighting of thin-wall packaging than ever possible before.

-

Molding Foam with a Smooth Surface

Three lines of Yizumi HPM presses are new adapted for the U.S. market. A large, two-platen model is molding MuCell foam with a hot/cold mold process.

-

Engel Rolls Out Decoject In-Mold Decorating Process

Fully automated cell that feeds a thin TPO film into the tool for back molding makes its North American debut.

-

Really Big Machines Dominate Milacron Booth

The largest machine at this NPE—or any NPE to date—is Milacron’s new 2250-ton Cincinnati machine. Not to mention the massive platen of a 6600-tonner now under construction, also on view.

-

Advances in Molding, 3D Printing At Arburg ‘Technology Days’

Over 6700 visitors saw more than 50 working machinery exhibits highlighting automation, connectivity, and sophisticated processing.

-

Trexel Forming Global Network For MuCell Engineering Support

Taking a more direct role in part, tool, and process design for specific applications.

-

K 2016 Preview: Injection Molding

Adapting injection molding to the concept of Industry 4.0 is gaining momentum. At this show you’ll see that the interconnected, integrated “factory of the future” is almost here.

-

Milacron to Show Wide Range of New Technologies at K 2016 Milacron

New developments in injection and blow molding, extrusion, hot runners, and tooling will be featured.

-

Tech Center Boasts Five Engel Machines and MuCell Technology

A new Detroit-area tech center gives automotive OEMs and their tier suppliers a production-scale lab to test the very latest molding technologies.

-

Trexel Establishes Detroit-Area Tech Center

Cooperating with Engel to provide Mucell-ready machines for trials.

-

Trexel Adds Chemical Foaming Agent to Its Product Line

Special additive offers economical microcellular foaming for low-volume jobs with PE, PP.

-

Materials at NPE: New Solutions to Enhance Processing, Performance, Sustainability & Cost

There was no shortage of new thermoplastics and additives covering the full range of end-use applications.

-

Here's Another Process for Foam Blow Molding

After two years of behind-the-scenes development, a new process for lightweight bottles emerges into the open.

-

Fibers Pair With Foam for High-Bending Stiffness at Low Surface Weight

Reduced clamp force, shorter cycles, lower melt viscosity, and higher dimensional stability are just some of the purported benefits of foam injection molding.

-

PP Formulations for Smooth-Surface Foam

Collaboration produces 10%-glass PP for the MuCell foam process without surface swirl.

-

Trexel’s Braig Re-appointed to U.S. Manufacturing Council

Council advises the Secretary of Commerce on government policies and programs that affect U.S. manufacturing and recommend ways to ensure that the U.S. remains the preeminent destination for investment in manufacturing across the globe.

-

INJECTION MOLDING AT NPE: Molding Exhibits Show Off Cell Integration with Multiple Processes & Operations

If you’re interested in lightweight composites, IML, LSR, multi-shot, inmold assembly, barrier coinjection, micromolding, variotherm molding, foams, energy-saving presses, robots, hot runners, and tooling—they’re all here in force.

-

Two New Alliances in Microcellular Foams

Trexel has licensed Milacron to supply turnkey MuCell systems for injection and blow molding, and joined with Lubrizol to develop a new TPU foam technology.

-

Updated: Taiwanese Molding Machine Manufacturer Accused of MuCell Patent Infringement

CLF's latest injection molding machine won a top innovation prize from Taipei Plas show organizers, but Trexel believes it violates its global microcellular foam patents.

-

Switch Over To Consistent Quality

A new process-control method picks up variations in melt quality and viscosity during the injection phase and equalizes them within the same shot.

-

Blow Molding News at K 2013

All-electric machines of all types were the stars of the show, but there were a number of other noteworthy developments.

-

Injection Molding at K 2013: Doing More with Less

More productivity with less energy consumption and capital investment; more operations in the machine or manufacturing cell with less time, labor, energy, and capital—these were the common themes of injection molding exhibits at October’s K 2013 show.

-

Headlines from the K 2013 Show

Here’s just a taste of the innovations on display, a selection of the top headlines not covered in our September show preview.

-

Foam's A Big Theme in Blow Molding at K 2013

WEB EXCLUSIVE: Trexel, MuCell, debut new technologies for automotive lightweighting.

-

Arburg Grabs Spotlight at K 2013

WEB EXCLUSIVE: At K 2013, injection machine builder introduces the Freeformer, a novel machine for additive manufacturing.. But there was plenty to see in hot runners, LSR processing, and lightweighting as well.

-

K 2013 Preview: Injection Molding

Next month’s mammoth triennial plastics show in Düsseldorf, Germany, challenges injection molding machine builders to demonstrate technological leadership in addressing the needs of the marketplace.

-

Higher Speeds, More Integrated Processes at K Show

“Go faster” and “integrate more functions” look to be the guiding principles of new injection molding developments to be shown by Engel Austria at K 2013 in Dusseldorf this October.

-

Novel Materials Stretch Process Capabilities

The potential for new or unusual materials to broaden the application potential of standard plastics processes was explored in a number of papers at April’s SPE ANTEC conference in Orlando, Fla.

-

First Commercial Use of ‘Dolphin’ Molding Process

italian molder deploys multi-component, hard/soft molding technology developed by Engel.

-

NPE: New Machines Exhibit Sophisticated Molding Demos

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

-

Injection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

-

Five Cases Where Microcellular Foaming Paid Off

The MuCell process for producing microcellular injection molded parts is used and accepted globally as a technology option for providing a more dimensionally stable part through a reduction in residual stress, along with increased productivity versus solid injection molded parts.

-

Microcellular Foam Goes Really Big

The world’s largest injection machine equipped for the MuCell microcellular foam molding process (above) was started up in December at the technical center of Mürdter, a German molder and moldmaker in Mutlangen.

-

Microcellular Instrument Panel Wins SPE Grand Award

The largest automotive component ever molded with the MuCell microcellular process—and also the first instrument panel ever molded with this process—won the Grand Award at the 2011 SPE Automotive Innovation Awards Competition last month.

-

Microcellular Foam with Heat-Cool Makes Class-A Glossy Parts

A high-gloss surface equivalent to automotive Class-A solid molding can now be achieved with the weight savings and other benefits of microcellular foam molding, thanks to a new licensing agreement between Trexel Inc., Waltham, Mass., and Ono Sangyo Co.

-

Microcellular Foam Molds 'Impossible' Parts

At the Molding 2011 Conference in San Diego last month, sponsored by Executive Conference Management (executive-conference.com), Markus Lettau, director of sales and application engineering for custom molder Empire Precision Plastics, Rochester, N.Y., discussed some of the unique capabilities of microcellular foam molding.Empire has three injection presses equipped for the MuCell foam process licensed by Trexel Inc., Woburn, Mass.

-

Taking the Temperature of Mold Productivity

Increasing traffic in transfer tooling from molders that have shuttered operations or are unable to successfully produce parts is driving interest in a long-established but under-utilized diagnostic technique for injection molding.

-

Foamed PET Bottles for Beer

Now the foam isn’t just on top of the beer, it’s all around it.

-

Tips and Techniques: Mold Filling Analysis Now You Can Adapt Injection Mold Filling Simulation for MuCell

While mold-filling simulation is a very common tool for predicting the fill patterns of an injection mold, in our judgment there is not yet a commercially available, satisfactory filling simulation for microcellular foam molding.

-

On-Site: An ‘Empire’ Built on Scientific Molding

A U.S. custom injection molder that’s hiring?

-

Injection Molding at NPE 2003

Show goers will see an electric injection machine in nearly every press maker’s booth this year, and electric/hydraulic hybrids in several.

-

NPE 2009 Wrap-Up: New Machinery for Injection Molding

New injection machinery at the show ranged from all-electric units for high-speed packaging or bioplastic processing to hybrid presses ready for the cleanroom. Other units highlighted multi-component molding with LSR and thermoplastics or super-compact presses for small parts. Several new machines targeted specific applications such as caps and closures, PET preforms, LSR, or integrated long-glass compounding.

-

NPE News in Blow Molding

While occupying a relatively small category of exhibits, blow molding will present no lack of innovation at NPE.

-

NPE News in Injection Molding

If a better machine can help your company beat challenging economic conditions, you’ll probably find it at NPE. And finding it will be easier, thanks to our editors’ efforts to sift out of some 2000 exhibits the most significant news in injection and blow molding, extrusion, compounding, and thermoforming.

-

Modular ‘Adaptable Automation’ Makes IML More Economical

Five years ago, in-mold labeling was just gaining traction among North American injection molders as a one-step approach to decorating without secondary operations.

-

New Light on How to Optimize Properties of Microcellular Foams

With the growing popularity of thermoplastic microcellular foams (such as those produced by the MuCell process of Trexel Inc.) comes increased need to understand how to optimize foam properties through appropriate foam structure.

-

What's New at the Show in INJECTION MOLDING

At the big “K” Show next month, top billing goes to new all-electric machines aimed at every segment of the market, from general-purpose to high-end.

-

New Injection Machines and Processes To Debut at K 2007

A brand-new line of all-electric machines priced on par with comparable hydraulic presses and the first public demonstration of insert molding RFID chips into plastic parts will be two highlights of the Engel display at the mammoth K 2007 show in Dusseldorf, Germany, this October.

-

New Screw Design for Long-Glass Microcellular Foam Molding

A combination of microcellular foam molding and long-glass fibers offers new potential for injection molding to penetrate large structural automotive parts such as door-module carriers, brackets, and front-end systems.

-

Hollow Glass Microspheres Stronger Spheres Tackle Injection Molding

Looking for a way to make lighter parts without giving up properties? New hollow microspheres are stronger than ever—enough to withstand the rigors of injection molding.

-

Rigid Packaging Goes Lighter, Thinner With Microcellular Foam

Molding higher volumes of a rigid thin-wall part typically means going to a larger press for increased injection and clamping capacity.

-

NPE 2006 News Wrap-Up: Materials

From PPs for frozen-food packaging to nylons and alloys that withstand the heat of circuit-board soldering or automotive paint ovens, NPE 2006 was rich in news of commodity and engineering resins and TPEs.

-

Automotive Insert Molders Try Microcellular Route to Precision Parts

Insert molders and assembly suppliers serving North America’s automotive industry have found a new range of benefits from the MuCell microcellular foaming process licensed by Trexel Corp.

-

Electric Machines and New Processes Catch Fire

The October show in Dusseldorf saw an onslaught of new all-electric and hybrid-electric presses, with modular designs, new clamping styles, and new sizes available from an ever-growing range of suppliers.