Blow Molding

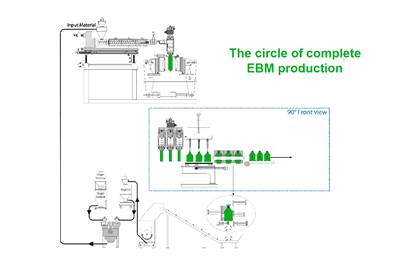

Blow molding is used in the manufacture of hollow plastic parts, creating common components like PET bottles, HDPE jugs, and jerry cans. Variations on the process include extrusion blow molding (EBM), injection blow molding (IBM), and injection stretch blow molding (ISBM).

Narrow Your Blow Molding Search

ESSENTIAL READING

VIEW ALLHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreFollow These Steps to Purge Accumulator-Head Blow Molders

Preventive purging with a commercial product between resins or colors and during normal shutdown and startup cycles can prevent excessive loss of resin and production time.

Read MoreWhat Blow Molders Say About All-Electric Machines

They are well established in Europe, but molders in North America are just beginning to come around to all-electrics’ improved performance, maintenance, cleanliness, and—yes— energy efficiency. Here’s first-hand testimony, from the U.S. and abroad.

Read MoreLatest Blow Molding News And Updates

All-Electric Shuttle and Stretch-Blow Machines

NPE2024: Meccanoplastica shows off a double-sided shuttle for containers up to 5 L and a reheat stretch-blow molder for up to 2.5 L PET containers with four cavities — both all-electric.

Read MoreNew 15-Ton, All-Electric Shuttle

NPE2024: Plastiblow demonstrates double-station, quad-head machine making 500-ml HDPE bottles.

Read MoreLarge Recip-Screw Machine Boasts Numerous Upgrades

Rocheleau adds side-shift option, new controls and diagnostics to its RS-90 unit.

Read MoreHigh-Output Drum Machine Boasts Fast Cooling, Color Change

NPE2024: Graham Engineering’s new 40-lb accumulator press has adjustable-height extruder platform.

Read MoreMidsize Electric Shuttle Blow Molder Balances Flexibility, Compactness

NPE2024: New Magic EBM model is loaded with features for the U.S. market.

Read MoreKrones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

Read MoreFeatured Posts

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreIn the Zone: Bottles

The Bottle Zone is the place to explore cutting-edge bottle and container technologies.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

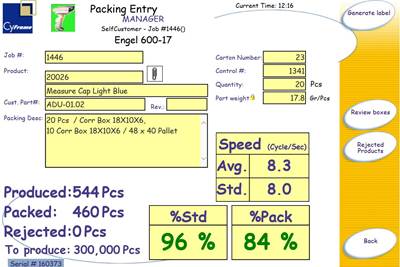

Read MoreUse Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreFAQ: Blow Molding

What Are Common PET Stretch-Blow Molding Problems and How Can I Fix Them?

Common problems:

1. Pearlescence and haze

2. Insufficient top-load strength

3. Insufficient base clearance or rocker bottom

4. Drop-impact failure

Fixes: https://www.ptonline.com/articles/solving-four-common-problems-in-pet-stretch-blow-molding

How to Fix Uneven Wall Thickness in Stretch Blow Molding?

There are a number of conditions that must be maintained in order to achieve the described result. Following are the various issues that can skew wall thickness, in order of relevance:

Off-center gate

Uneven heating or cooling

Small stretch ratios

Part failure along the parting line is related to material processing conditions, parison geometry, molding conditions, mold design, or a combination of these factors. Developing the optimal material shape inside the part at the pinch-off is a key to building parting-line integrity.

Blow Molding Supplier Categories

- Rebuilt Screws or Barrels

- Thermoformers

- Automation/Systems Integration

- Platens

- Thermoforming Molds

- Extrusion Blow Molding Machines

- Recycling--Purchasing Scrap or Waste Plastics

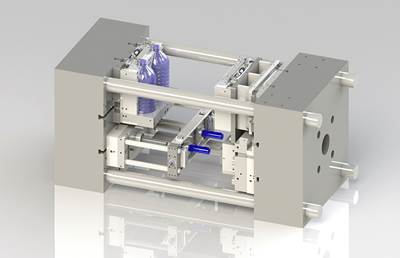

- Blow Molds

- Technical and Trade Associations

- Pre-expanders, Polystyrene Bead

- Trimmers, Deflashers for Blow Molding

- Custom Compounding, Formulating--Thermoplastics

- Stretch-Blow Molding Machines

- Barrier Surface Treatment

- Plastics Trade Shows/Conferences

- Machine Alignment Services

- Nonferrous Metals for Molds

- Machinery Rebuilding

- Training Programs in Plastics

- Mold/Die Management Systems

- Shipping & Logistics

- R&D, Training Institutes

- Rebuilt Motors and Drives

- Injection Molds

- Mold Steels

- Injection Blow Molding Machines

- Prototyping Services

- Dip-Blow or Compression-blow Molding Machines

- Cutting, Stamping, Trimming Dies

- Mold/Tooling Simulation and Analysis Services

- Quick-mold-change Equipment

- Mold Making and Repair Equipment

- Parison Programmers

- Mold Components

- Custom Machine Builders

- Injection Blow Molds

- Custom Size-reduction (Grinding) Services

- Consultants - Design, Manufacturing, Purchasing

- Presses, Polystyrene Bead

- Spray Coating Systems (for Bottles)

- Rotational Molds

- Part/Mold Inspection or Digitizing

- Inserts

- Materials Testing Services

- Accumulators (Melt)

- Hydraulic Oil Filtering/Reclaim Service

- Structural Foam Machines (for Thermoplastics)

- Tool Engraving, Texturing Equipment

- Publishers of Plastics Information (Books, Reports, CDs)

- Mold Texturing, Tool Engraving

- Mold Evacuation Systems

- Mold Grease

- Rotational Molding Machines

- Machine Installation Services

- Hard Facing, Surface Treating of Tooling, Equipment

- Mold/Tooling Design Services

- Compression/Transfer Molds

- Business Services for Plastics (Finance, Insurance, Leasing)

- Mold-cleaning and Maintenance Chemicals

- Nonmetallic Tooling Materials

- Hot Runner Components

- Radiation Processing Services

- Machine Maintenance Services

- Used Molds

- Used Machinery

- Environmental Monitoring and Analysis

- Equipment Cleaning Services

- Custom Decorating/Finishing Services

- Foam Molds

- Compression/Transfer Presses

- Prototype Molds

- Scanning & Metrology Services