Extrusion

Coiling System Features Automated Spool Removal

NPE2024: Designed for wire and cable and tubing, system is equipped with a Yaskawa cobot for automated spool removal.

Read MoreEnhanced Dry-Ice Cleaning Systems for Screws, Tooling

NPE2024: Cold Jet will be displaying four new dry-ice cleaning solutions for screw and tooling, and will also offer booth visitors a chance to win one of them.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreExtruder Controls Make for More Energy Efficiency

NPE2024: Twin-screw extruders packed with features to optimize energy consumption.

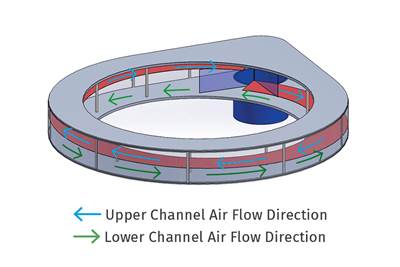

Read MoreSingle-Inlet Plenum Air Ring Improves Gauge Control

NPE2024: New design also eliminates multiple hoses to clean up production area.

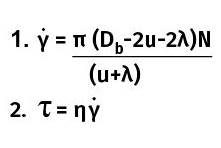

Read MoreWhat You Need to Know About the Design and Operation of Maddock Mixers

Designed properly, all entering solid polymer fragments and certain types of PE gels entering the Maddock mixer can be trapped and dispersed into the matrix resin. But many are not properly designed. Here’s what to look out for.

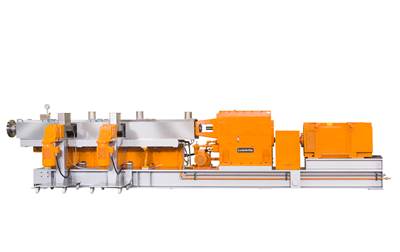

Read MoreEquipment for Compounding, Reactive Extrusion, Devolatilization, Foaming and Direct Extrusion

NPE2024: Leistritz to focus on advances made via twin-screw extrusion.

Read MoreRefurbishing Service for Biax Lines

NPE2024: Clip and chain systems for film-stretching lines can now be overhauled in the U.S.

Read MoreAuto-Profile System for Blown Film Rotating Dies

NPE2024: New technology can slash gauge variation by 50%.

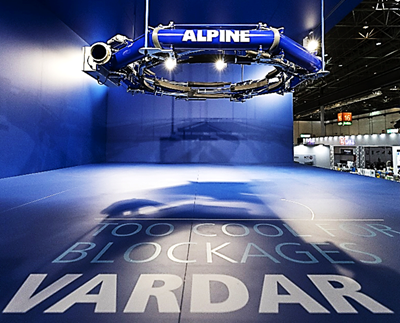

Read MoreNovel Cooling System, Energy Efficient Extruders for Blown Film

NPE2024: Tower-mounted, variable-diameter air ring and flexible, energy-efficient extruder highlight Apline display.

Read More

.png;maxWidth=300;quality=90)