Tooling

Compact Collapsible Core Features Independent Movements

NPE2024: DME’s DURA collapsible core’s two-piece design enables each segment to open and close independently.

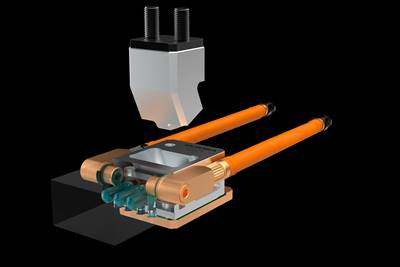

Read MorePlug-and-Play Modular Hot Runner Controller

NPE2024: Spark Industries’ patent-pending MOD24 hot runner controller offers unlimited plug-and-play of 6-zone hot runner control modules.

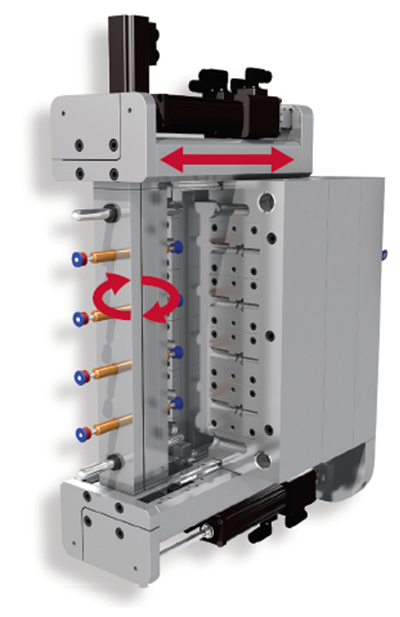

Read MoreCooling Added to Compact Slide

NPE2024: CUMSA adds cooling to the Compact Slides (CS) line launched last year.

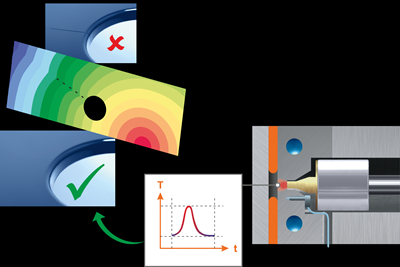

Read MoreMovable Tempering Stamp Can Eliminate Surface Defects

NPE2024: Incoe says Heat-Inject Technology introduces localized heat to remove weld or knit lines, or help melt flow into hinges, thin walls, delicate geometries or microstructures.

Read MoreHot Runner Temperature and Mold Motion Controllers Debut

NPE2024: Hot runner systems, temperature and motion controllers, an auxiliary injection unit and a gate seal are among Mold-Masters’ show plans.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

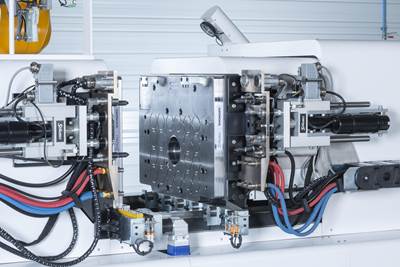

Read MoreMagnetic Mold Clamping Amplifies Quick Mold Changes

NPE2024: Stäubli highlights its adaptable QMC123 technology, which is capable of calculating the clamping force for each mold beforehand, in addition to ensuring worker safety.

Read MoreFast-Response Hot Runner Controller

MCS hot runner control systems from PCS company are designed to optimize performance, communication and control.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreAmerican Injection Molding Institute Opens Mold Maintenance Classroom

The Beaumont subsidiary has opened the Mold Maintenance Center of Excellence classroom at its Erie, Pennsylvania, headquarters.

Read More