Multiscrew

Latest Multiscrew Articles

VIEW ALLStrategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

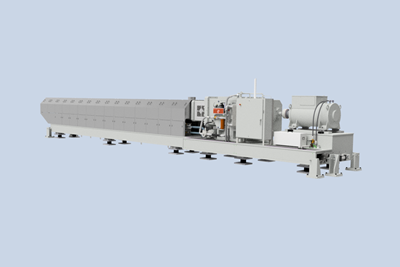

Read MoreNew Machines, Spare Parts and Auxiliaries for Compounding

NPE2024: ENTEK displaying a range of products at the May show.

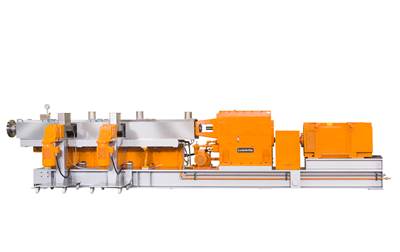

Read MoreEquipment for Compounding, Reactive Extrusion, Devolatilization, Foaming and Direct Extrusion

NPE2024: Leistritz to focus on advances made via twin-screw extrusion.

Read MoreTwin-Screw Showcased in Circular Economy Demo

A KraussMaffei twin will upcycle pelletized blood vials, which will then be overmolded on another press to produce bottle openers.

Read MoreConfiguring the Twin Screw Extruder: Part 4

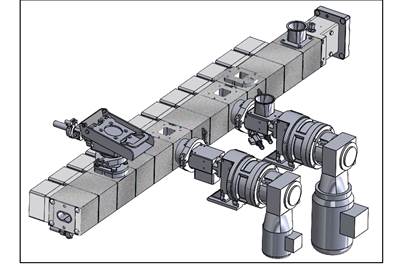

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreProgram Helps Compounders Configure Screw, Barrel Layout

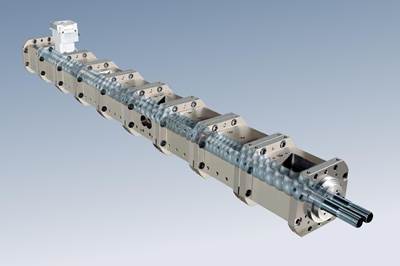

New software from ENTEK is said to make it easier for compounders to design their own screw and barrel configurations.

Read MoreLatest Multiscrew News And Updates

Peak Performance Gets ISO 13485:2016 and 9001:2015 Certifications

Toll and custom compounder gets certified less than a year after it produced its first pellet.

Read MoreCompounding: Closed-Loop System for Coex Film Reclaim

New system permits reclaim of multi-layer production scrap at rates up to 100%.

Read MoreNordson Opens Pelletizing, Melt-Delivery Lab in N.C.

Lab has pelletizing line that can operate at rates to 1000 lb/hr.

Read MoreCompounding: More Digital Solutions Come to Compounding

New GUI, ‘smart machine’ features, user friendly app highlight Coperion’s display at K 2019.

Read MoreCompounding: Revamped Line of Compounding Twins

Third-generation iMAXX twins are easier to clean and maintain, and are more energy efficient to boot.

Read MoreCompounding: Quick-Color-Change Lab Twin

Throughout the exhibit, KraussMaffei ran nine different liquid colors, changing at the push of a button, to demonstrate time- and process-saving technology.

Read MoreFeatured Posts

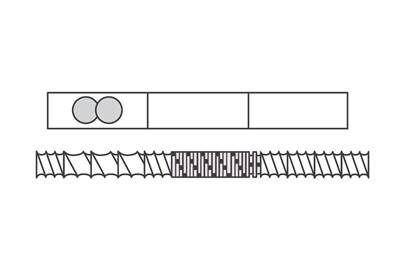

How to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreHow to Configure Your Twin-Screw Barrel Layout

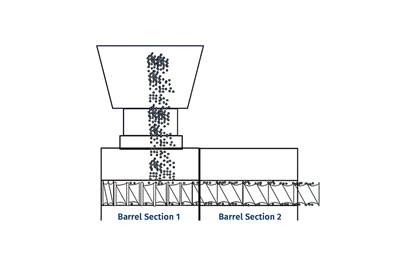

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

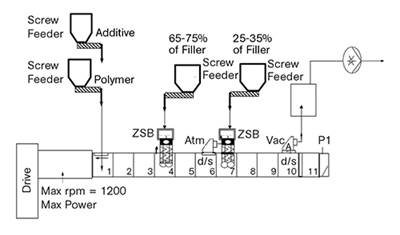

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read More10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreLFT-D Thrives in Automotive and Other Durables

Teijin Automotive acquires its 10th direct long-fiber thermoplastic system as demand for this technology soars.

Read More

.png;maxWidth=300;quality=90)