'Cleaner,' More Efficient Additives for Flexible and Rigid PVC

New vinyl additives designed to be more environmentally friendly while offering improved performance are available from Crompton Corp., Middlebury, Conn.

New vinyl additives designed to be more environmentally friendly while offering improved performance are available from Crompton Corp., Middlebury, Conn. Among the firm’s latest developments are low-VOC heat stabilizers for flexible and rigid PVC and impact modifiers for rigid PVC.

Stabilizers for flexibles

The Mark 9300 Series of CaZn and BaZn liquid heat stabilizers were originally developed for low VOC emissions in general-purpose flexible PVC. They have less than 10 ppm phenol content, and they resist hydrolysis and free-phenol formation, suiting them for low-emission indoor flooring and auto interior uses. More recently, another advantage of these products has become apparent. They also have very low phosphorus content—under 2.5%—compared with 3% to 5% for conventional mixed-metal liquid stabilizers. Higher phosphorus content has been found to be related to problems of exudation and poor printability.

Included in this series are Mark 9306, a low-phosphite CaZn, and Mark 9302, a high-efficiency BaZn. These stabilizers reportedly confer low plate-out, higher resistance to oxidation, good clarity, and better heat stability than conventional mixed-metal liquids. They are also said to provide good printability due to the low plate-out, and finished products survive very well in hot, humid climates and during warehouse storage. These stabilizers are premium priced but they can be used at 20% to 25% lower levels (2 to 3 phr) than conventional stabilizers in many applications.

Crompton is also developing a new tri-metal (CaKZn) liquid. Recommended at 2 to 3 phr use levels, this heat stabilizer has been shown to outperform conventional BaZn stabilizers in clear and filled flexible compounds for uses other than wire and cable. FDA approval for food contact is expected.

Also new is a solid CaZn heat stabilizer, Mark 6796, recommended for wire and cable jacketing, light-duty primary insulation, and general-purpose flexible PVC extrusion. The product is said to halt die-lip drool and is used at 3 to 4 phr as an alternative to lead or Ba/Zn stabilizers.

Another new solid CaZn is Mark 6797 for heavily filled, flame-retardant compounds used in plenum jacketing. The stabilizer reportedly will not add to flammability or smoke generation, unlike many other stabilizers. Typical use levels are 2.5 to 8.0 phr.

Mark 6784 ACM is a new solid CaZn for primary building-wire insulation. It’s reportedly the first alternative that meets UL83 standards, both wet and dry. Typical use level is approximately 4 to 6 phr.

Mark 6790 is a solid CaZn stabilizer for automotive interiors, where there is a trend to replace BaZn heat stabilizers in flexible applications such as door and instrument panels. Used at 2 to 3 phr, the product boasts very low fogging.

Stabilizers for rigids

Low-volatility heat stabilizers for rigid PVC also number among Crompton’s new offerings. One example is Mark 3166, a liquid methyltin for rigid calendering and profile extrusion. It boasts very low odor and is recommended at 1.20 to 1.50 phr.

Mark 2915 is a new liquid butyltin stabilizer for rigid foam profiles and sheet. It is said to act both as a stabilizer and an activator for azodicarbonamide foaming agents. It reportedly provides 10% lower foam density than standard tin mercaptides and is self-lubricating, which is said to produce surface smoothness and less pinking. Use level is typically 2.5 phr.

Also new is Mark 2914 butyl-based tin stabilizer for fencing and window profiles. It offers improved flow, allowing for higher output rates. This product was developed to minimize plate-out and chatter in the calibrator at high line speeds. It is said to provide excellent long-term heat stability. Use levels are 1 to 1.5 phr.

Crompton has a new liquid methyltin one-pack stabilizer/lubricant package for NSF- and PPI-approved PVC pipe. Mark 2910 is said to be the first self-lubricating (paraffinic) methyltin on the market. It eliminates the need for paraffin wax and provides the heat stability required for pipe extrusion. At use levels of 2.0 to 2.3 phr, this additive has been shown to greatly reduce plate-out and to allow for a higher flow rate from the die.

Crompton is also developing CaZn stabilizers that can offer improved weatherability of white window and fencing profiles in hot, arid climates. One example is TS 1206, a solid CaZn one-pack with internal and external lubricants, recommended for use at 4 phr. It is said to help prevent surface degradation and yellowing due to uv, heat, and dryness. Crompton will develop a series of these products to match user needs in terms of color development and long-term heat stability.

Modifiers for rigids

Since its 2003 acquisition of GE Specialty Chemicals, Crompton has further expanded the Blendex line of impact modifiers for PVC. New for rigids is Blendex 338, an ABS impact modifier designed for the non-weatherable substrate layer of siding and fencing. According to Crompton, it acts as a fusion promoter, so that it can be used at lower levels than acrylic impact modifiers—2 to 3 phr vs. 4 phr, with no processing aid added. In addition to lower concentrations, this modifier allows for higher filler levels, which permit further cost savings.

Related Content

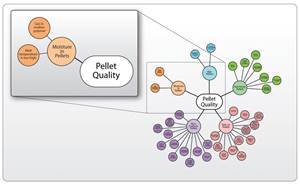

The Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

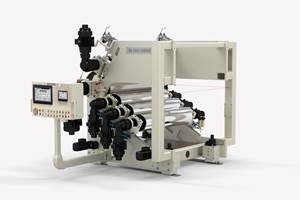

Read More10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

Read MoreConfiguring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=300;quality=90)

(1).png;maxWidth=300;quality=90)