A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Like many “crusty” veteran processors, I do not like admitting my mistakes. Yet, in a column in wrote in October 2011, I tackled the topic of calculating shot size vs. barrel capacity and—upon further review—concluded the article had some flaws. So, here’s a second try with simpler advice.

Calculating shot volume to make sure your barrel has enough capacity seems like a dull topic. But trust me, you’ll have a significant emotional experience if you were to put a mold in a machine only to find out there is not enough barrel capacity to make the part. Especially if it is a new machine you bought for that mold.

Perhaps that has never happened to you, but I do get emails about this, and my answer is never well received. Most molders don’t like to hear they need to buy a new barrel, because of the time and cost involved. So, if you are buying a new machine or scheduling a mold to a machine, do your homework before the machine is ordered or the schedule is set.

Do your homework on the barrel capacity you’ll need before the machine is ordered.

Most likely you’ll have a variety of part sizes, so it is unlikely you will find a one-screw-size-fits-all remedy. Some molders go with the biggest screw possible, but do not do this, as it will cost you more money long term.

Super-small shot sizes, using less than 20% of the barrel capacity, often lead to long residence times, which in turn lead to polymer degradation and poor process control. Plus, big screws usually mean lower plastic pressure capability. Large shot sizes, using greater than 65% of the barrel capacity, tend to have melt-quality issues like unmelt, poor melt uniformity, and long screw-recovery times.

It’s great if you find one screw that can accommodate all your parts; but if not, consider ordering two barrels. Two barrels will allow even a greater range of molds. You may be surprised at the low price of a second barrel when ordered with the new machine. Properly specified and with a skilled operator, barrels can be swapped in less than 30 min, even if the barrel is hot.

How do you figure out what barrel/screw size you’ll need? If it is a new part and the mold hasn’t been built yet, running a mold-filling analysis will give you the volume of the part and runner. If your mold is in the building stage, your moldmaker may have calculated the volume of your shot—and make sure to also include the runner volume if it’s a cold-runner mold. If you already have the mold and you are purchasing a new machine, you have two sets of data: the part and runner weights, plus the shot size of the existing machine. With either part plus runner weight or the volume of the total shot, you have your starting point. So how do you do the calculation?

Let’s start with the scenario in which you know the part weight. I like to work in grams but most machine specifications are in ounces. If the part, runner (cold), and sprue together weigh 164 g of PP, that comes to 5.8 oz (164 g/28.3 g/oz). Assuming you have a barrel capacity of 8 oz, you might be tempted to conclude that you have plenty of shot volume available. Unfortunately, this is where things start to unravel.

First, look at the machine specification, it usually is in grams or ounces (weight) of PS. So the machine specification is 8 oz, or 266 g of PS(8×28.3 g/oz = 226 g).But you want to mold PP. There is an important density difference between these resins. At room temperature, the density of PS is 1.04 g/cm3 and PP has a room-temperature density 0.90 g/cm3. You cannot compare your PP number to the machine specification because of the difference in densities between materials. So, for your 164 g shot size you need to correlate the PP grams to PS grams. For your 164 g part, the conversion factor is not 28.3 g/oz but 28.3 times the ratio of densities: 164 g/28.3 g/oz × 1.04/0.90 or 6.72 oz equivalent to PS. So comparing this new PS equivalent oz to the machine specification of 8.0 oz, you’re still okay, right?

Unfortunately, this is when Mr. Murphy usually enters the equation to remind you that what can go wrong usually does. He’ll remind you that these are room-temperature densities, and in molding (that is in the hot barrel) we deal in melt-temperature conditions. Sorry, here’s another step of complexity. You must work with melt densities.

When melted, the polymer molecules are farther apart and density decreases. Melt densities are not often found on the material specification data sheet. Usually they can be found using your search engine. (Plastics Technology’s Universal Selector is one place to check). For PS, the melt density is 0.945 g/cm3 and for PP it is about 0.74 g/cm3. This changes our calculation; it is now 0.945/0.74 or 1.28. Now we need a minimum shot size of 7.4 oz (164 × 1.28 = 210 g or 7.4 oz). We are still (just barely) within our 8-oz barrel capacity, but Murphy isn’t done with us yet.

Is it practical to attempt to use 93% of the barrel capacity (7.4/8.0 oz)? No, that is not going to work. My recommended working range for a barrel is between 25% and 65% of the barrel capacity. Then I add in another 10% safety factor, for check-valve leakage and melt uniformity. So the real target is 7.4 + 10%, or 8.14 oz shot size in PS equivalents for PP. Seeking to use only 65% of the barrel, final calculation is (0.65 x = 8.14) or 12.5 oz barrel capacity in PS units.

Will you be molding crystalline or amorphous materials?

But why the extra barrel capacity? Because you’re melting plastics and you need to understand how this happens. There is a difference in how certain polymers melt. In particular, understand that PP is a semi-crystalline resin, which melts differently than amorphous resins. Semi-crystalline resins stay hard up to their melting point, and normally require twice as many BTU/g to melt than amorphous resins. This double whammy makes semi-crystalline resins significantly harder to melt uniformly than amorphous resins.

Think about it: In a 20:1 L/D screw, you have 10 flights for feeding (little to no melting in this section); five flights of transition or compression, where melting occurs; and five flights in the metering zone, which are designed not to melt but to pump or push the plastic through the non-return valve to build backpressure and your shot. These are significant factors that are not obvious, but they are the reason you need a larger barrel.

Simplified message: Stick with volume and melt densities. Do not work in weights. The barrel is basically a big syringe. Again, with a 164 g shot of PP, the calculations would be: 164 g/0.70 g/cm3 or 234 cm3 volume for PP. Add 10 % for safety = 257 cm3. Barrel size needed: 0.65 x = 257 cm3, x = 395 cm3. If you work with volumes for the screws available, you are done. If you need to work in weights, convert the 395 cm3 to grams of PS using the melt density of PS which is 0.94 (0.94 × 395 = 371 g pf PS or roughly a 13 oz barrel).

Bottom line: Take the time to do the shot-size calculations. True, it’s a pain to do and double-check, but otherwise you are inviting Murphy to your party and he won’t be bearing gifts. If all this is too much, email me and I will send you a free spreadsheet to do these calculations, making your day a bit easier. You plug in the grams and resin melt densities, and it calculates the suggested barrel capacity in ounces.

ABOUT THE AUTHOR: John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com.

Related Content

Solve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreUnderstanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreAre Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

Read MoreRead Next

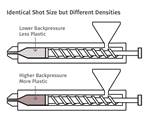

Injection Molding: How Backpressure Adjustments Influence Shot Size

Raising backpressure results in increasing shot size, which can cause a host of other problems.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More.jpg;width=70;height=70;mode=crop)