Air Rings--Make Them Work for You, Not Against You

Air rings do more than just blow cooling air on your film. Their complex aerodynamic effects also help form and stabilize the bubble. Yet operators often misuse air rings because they don't understand how the stabilizing function works. Here's a practical guide to making an air ring be your trusty helper instead of an unruly troublemaker.

Understanding air-ring control eludes many blown-film operators. Even experienced operators may see air rings as erratic or mysterious. Adjustments that worked to control a problem yesterday may seem to have no effect today. Also, much of what works is based on educated guesses, not firm knowledge. Ask even experienced operators the purpose of an air ring, and the typical answer is that it is supposed to cool the bubble evenly. A more complete answer is that air rings also control bubble stability.

The mystery about air rings lies in the stabilizing function. This is partly the fault of the way operators are trained. They're taught to use the air ring primarily to control the frost line on the bubble. Increasing air supply to the ring brings the frost line down; decreasing it allows the frost line to rise.

Too much of a good thing

On a hot afternoon, the frost line can rise because of warm ambient air (that is, if you're using tower-cooled air rather than chilled air). When the frost line rises too high, operators typically increase air delivery to the ring to increase cooling on the bubble. But turning up the air has other more subtle effects on bubble stability.

Stability is not completely controlled by the adjustable iris aperture or by any bars, rollers, boards, or other guide assemblies in the tower. Air rings also control bubble stability using a principle known as the venturi effect, which is a partial vacuum caused by the flow of air over the bubble. So increasing or decreasing air delivery also increases or decreases this suction effect on the bubble.

Increasing air delivery tends to pull the bubble closer to the walls of the air ring. In areas where the gauge is thinnest, it may actually pull the bubble off-center until it touches the air-ring wall. Slight contact with the wall leaves a pattern of transverse stripes on the film. Heavier contact with the wall may even collapse the bubble.

This effect isn't usually immediate unless the increase in air volume is fairly significant. More often, the process drifts gradually out of balance. The bubble may appear stable for several minutes or longer before the onset of visible problems. By then, the operator may not even be in the immediate area. It's always good advice for operators not to go on break within 10-15 minutes of making an adjustment of air delivery to the air ring.

Read the lips

A change in height of the main lip of the air ring can have the same delayed effect of destabilizing the bubble. Height adjustment has no effect on the volume of air, but on its velocity. Lowering the lip tends to increase the venturi effect by increasing the speed of air flow. Conversely, raising the lip decreases the venturi effect by slowing the air flow. This is similar to clamping your thumb over the end of a garden hose when you're washing the car. (Your thumb narrows the opening, thereby increasing the speed of water flow while the volume remains unchanged.) Once a film line is in production, a 1/16-in. adjustment in air-ring height is significant, and a 1/8-in. adjustment may actually be enough to cause the line to go out of production and produce scrap.

To complicate matters further, many blown-film lines run dual-lip air rings. Some have adjustable inner lips, or cones, and some don't. Any adjustment to the main (outer) lip opening will also affect the venturi established by the height setting of the first (inner) cone. If this inner lip isn't set within a very specific height window, a change to the main lip easily upsets the previous balance because of the combined venturi forces from the two separate lip openings.

If the inner lip is movable, there may be a problem with its height, which is masked by the combined venturi at the main lip. An operator may not recognize the problem or may attempt to correct it by adjusting the main lip. The operator may then find that only a slight adjustment to the main lip makes the bubble suddenly very unstable. If the operator then tries returning the main lip to the previous setting where the bubble was stable, it won't work if the root of the problem is the height of the inner lip, not the outer one. What's more, the overall window of adjustment becomes much tighter, so even slight changes of air delivery can easily take the line out of production.

The inner cone and main lips can also loosen over time. Thread inserts intended to keep these assemblies from moving may not be maintained regularly. When that happens, air pressure or vibration can move the lips. If operators realize this is happening, they may tape outer-lip assemblies in place. But gradual movement of the inner cone is more difficult to see. This problem can't be fixed until the line is taken down and the air-ring lip assemblies are removed for cleaning. Restoring the inner cone closer to its original position will broaden the operating window.

Operators tend to be familiar with certain combinations of main-lip height and air pressure. If the inner ring is properly located, these habitual combinations will work. If the inner ring is not in the right position, the usual set-up combinations will not work and the window of adjustment will be smaller. Then any change to air delivery is more likely to cause problems.

What's more, problems of air-ring movement also tend to work gradually to reduce the window of stable operation, making it more difficult for operators to determine the true cause of instability.

Air-ring operation is also difficult to learn because blown-film extrusion is susceptible to ambient influences. Drafts may cause localized cooling or may draw the bubble out of concentricity with the air ring. This effects make for uneven film thickness, which leads to uneven rolls. Gauge bands will not show up on rolls made with oscillating tower assemblies because the oscillating mechanism randomizes gauge variations. They're still there, but spread out over the roll.

Observant operators will recognize the difference in blown-film operation when ambient conditions change. The same line running the same resin and product will run very differently on a hot afternoon versus a cool morning or night. Operators who don't follow the subtle indicators won't be able to adjust the process before the line goes out of production.

Don't over-adjust the air

Operators should be trained to find the lip-height and air-pressure settings that initially give the widest window of control. When it's necessary to change frost-line height, rather than adjust air delivery, it's better for operators to look first at process conditions and then for changes in the ambient environment. The right adjustment may well be to lower the melt temperature, not raise the air delivery. Conversely, melt temperature may have to be raised again as ambient temperature drops later in the day.

If you want more consistent operation, leave air-ring settings pretty much alone once a line is in production, and work with melt temperature to control frost-line height. This approach maintains the bubble control that has been established by the venturi in a much tighter window than will occur if you use air delivery as your primary means of adjusting frost-line height.

Gregory Moriarity has 25 years' experience in production, R&D, manufacturing, process engineering, field service, and production management. He has worked in extrusion of all types of film, as well as sheet, strapping, blow molding, and recycling. He is now president of his own firm, Northwest Extrusion Associates, Inc., in Arlington, Wash. It provides extrusion training and troubleshooting services.

Related Content

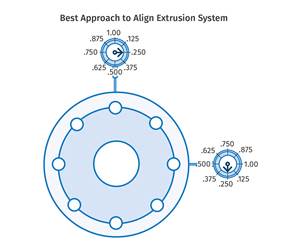

Extruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreSpecialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More.png;maxWidth=970;quality=90)