OEM Sees Predictive Maintenance As Key to Equipment Utilization

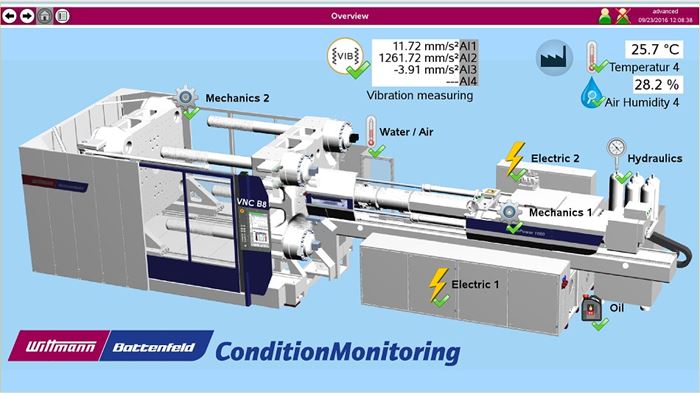

Wittmann Battenfeld's new Condition Monitoring System debuted at K 2016.

Last month, at K 2016 in Dusseldorf, Wittmann Battenfeld of Austria (U.S. office in Torrington, Conn.) joined a slowly building wave of attention by equipment OEMs to the concept of predictive maintenance as an essential strategy for obtaining maximum machine efficiency and uptime (see our blog on the topic). Wittmann Battenfeld also sees its new Condition Monitoring System (CMS) as an element of the networked Smart Factory, or Industry 4.0.

CMS is implemented via the company’s new B8 control system, the new standard for all its machines. With the help of CMS, important machine data are measured by sensors, processed by special software, and subsequently analyzed by technical experts at the plant and/or at Wittmann Battenfeld, if the customer wishes. CMS thus combines technology with human diagnostic competence. The data to be analyzed are vibrations, torques, temperatures, air humidity, oil quality, water flow, screw function, and all data from the control cabinet. Wittmann compares it to Formula 1 racing, where the vehicle data are analyzed on every circuit of the track in order to keep the car operating at optimum performance and to call it in for maintenance before a breakdown is imminent. According to Wittmann, the key is to “know what to listen for, how to interpret it, and when to put this knowledge to use.”

Among the factors to be sensed and analyzed are oil quality (particle count), temperature, level, and moisture content; water quality, flow, and temperature; vibration in the clamp and injection unit; torque measurements (one way to detect a bad screw-tip assembly); injection stroke; water flow and temperature; compressed-air flow and pressure; electrical function of the B7 controller and power supply; smoke alarm in the control cabinet; and ambient humidity. Both alarm levels and “prewarning” levels can be set—and the system can automatically send alert emails to maintenance technicians.

Related Content

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

What to Do About Weak Weld Lines

Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate.

-

How to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.