February 2015 Issue

January 2015

Features

Featured articles from the February 2015 issue of Plastics Technology

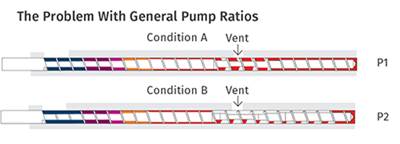

EXTRUSION: Avoid General ‘Pump Ratios’ On Two-Stage Screws

Instead, rely on basic data and calculations to determine the proper depth of the first and second metering sections

Read More

RheTech Agrees To Acquisition By Hexpol

Sweden's Hexpol is acquiring Michigan's compounder RheTech.

Read More

Akcros Invests In Safe, High-Quality Biocides

The start-up of manufacturing of pelletized isothiazalone-based biocides is underway at Akcros's New Brunswick facility.

Read More

Molder’s Mantra: Go Lean, Stay Green

All-electric presses combined with home-built technologies and energy-efficient initiatives at PMT.

Read More

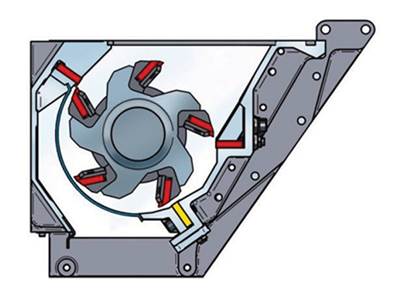

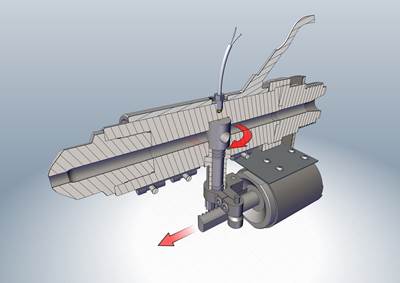

Energy-Efficient Granulating

Granulators are notorious energy hogs, but motors and designs have improved energy efficiency over the years. Proper selection and maintenance can also do a lot to avoid wasted energy cost.

Read More

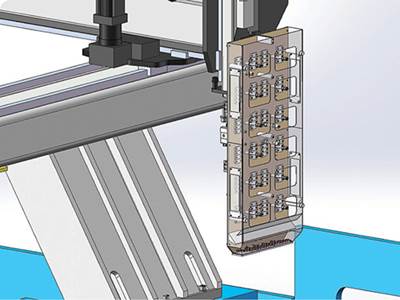

Robot End-of-Arm Tooling: Making a Big Difference

Often overlooked as a small part of an automation system, clever end-of-arm tooling techniques and designs can improve part quality, heighten efficiency, and eliminate headaches for any molder.

Read More

Wellman Plastics Recycling Part Of Shanghai Prett Composites

Wellman Plastics Recycling is being acquired by automotive plastics compounder Shanghai Pret Composites.

Read More

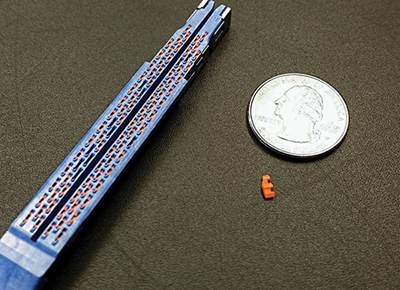

Micromolding Gets Bigger at Tessy Plastics

Micro parts are a tiny but fast-growing segment of its custom molding business, with potential to expand beyond the medical sector.

Read More

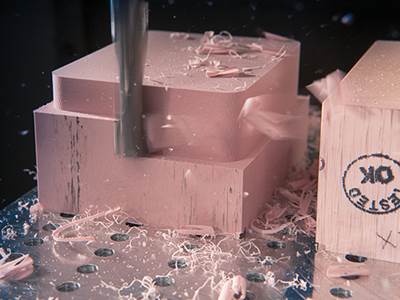

Five Steps Toward Better Plug Assists

With careful planning and adherence to best practices, crafting the right plug assist can put you on the path to high-quality, repeatable parts.

Read MoreMachinery Innovator Dewey Rainville Dies at 91

Developed numerous technologies in blow molding; involved in start-ups of leading auxiliary equipment firms.

Read More

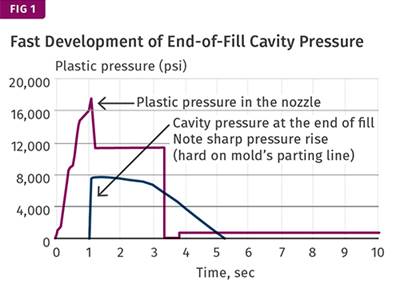

INJECTION: First to Second Stage Transfer: Should There Be ‘Bounce-Back’?

How much screw ‘jumping’ or bounce-back can your process tolerate? The answer is no surprise: It depends

Read More

Metabolix To Significantly Boost PHA Production

Plans are underway at Metabolix to increase output of PHA biopolymers.

Read More

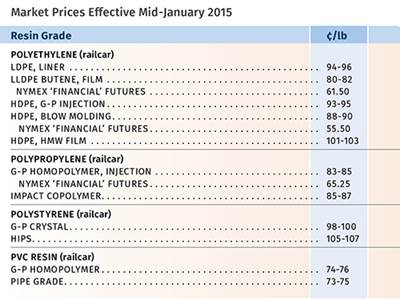

Commodity Resin Prices Still Dropping - January 2015

Led by lower global feedstock and resin prices, commodity resin prices continue to decline.

Read More

Conair Lab Devoted to Pipe, Profile, Tubing Extrusion

New lab can develop and test complete extrusion systems for precision medical tubing to siding.

Read More

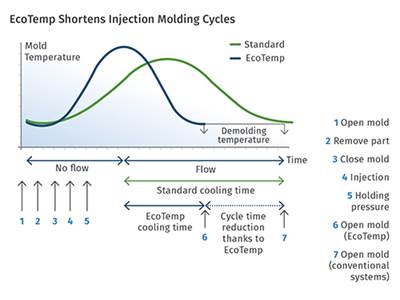

‘Passive Variotherm’ Cooling Cuts Cycle Time at Low Cost

A hot/cold molding technique lets the injected melt do the heating while water flow is paused.

Read More

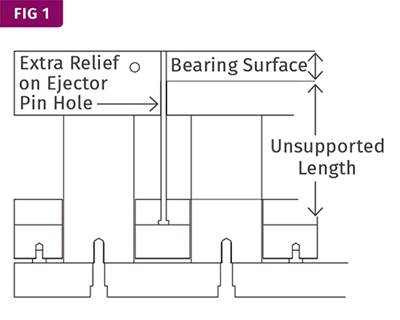

TOOLING: Ejectors: Watch That ‘Unsupported Length’

It may be an unfamiliar term, but it’s the key to preventing ejector-pin deflection and breakage

Read More

SPI Launches Sustainability Benchmarking, 'Zero Waste Zone'

SPI is surveying members on sustainability practices to provide guidance for companies to improve their own practices. A Zero Waste Zone at NPE will highlight sustainable practices.

Read More

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read More

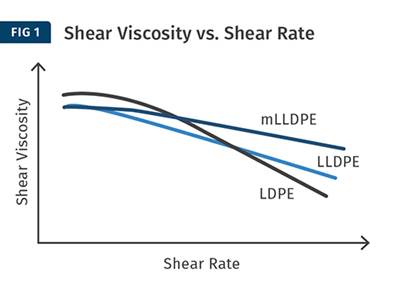

Coextruding Blown Film Needs Deeper Understanding of Resin Rheology & Die Design

More film processors are investing in lines with nine or more layers. With more resin possibilities and combinations coming into play, it’s important to learn more about material rheology and compatibility, as well as die design.

Read More

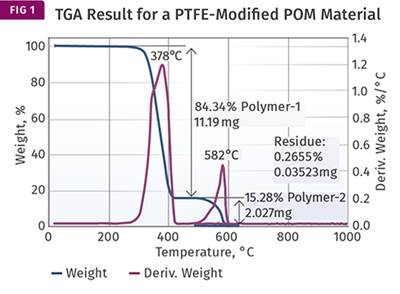

MATERIALS: Analysis Gone Wrong

A lot of resources are devoted each year to trying to figure out why products fail. Sometimes it’s because no one involved in a project realizes the data provided was wrong.

Read More

Detect When Equipment Needs Maintenance—Before It’s Too Late

New technology to debut next month at NPE warns when preventive maintenance is needed, before equipment failure disrupts production.

Read More

Reedy International Gets New Name

Along with new headquarters, Reedy International has the new name of Reedy Chemical Foam & Specialty Additives.

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)