Athena Controls “Zones” Into Expanded Hot Runner Control

Athena Controls Inc. is featuring two new lines of hot runner controller systems during NPE2018 this week.

Athena Controls Inc., a designer and manufacturer of hot runner temperature sensors and controls for plastics molding since 1965, is featuring several new products at NPE2018 (Booth W5455).

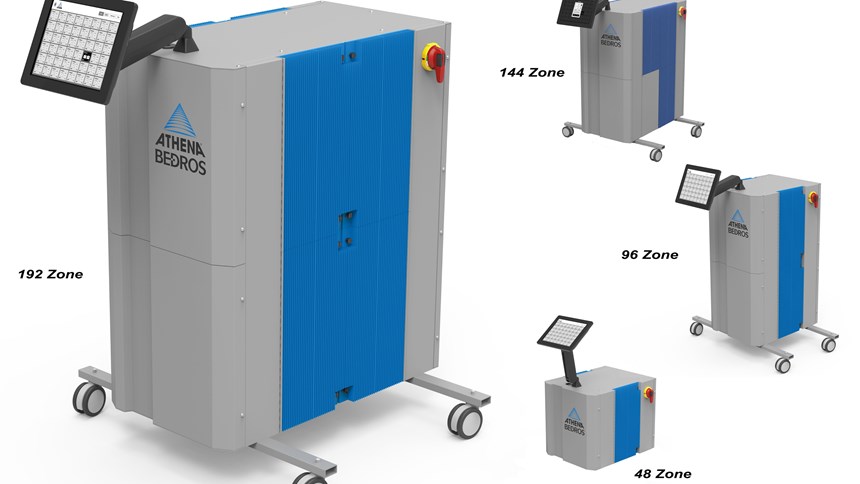

NPE attendees will have the opportunity to view two new lines of hot runner controller systems, according to Bill Crawford, vice president of sales and marketing at Athena. “Our featured products include four new models from the non-modular BEDROS line of hot runner controllers. We have greatly expanded the line’s capabilities by now offering systems with a maximum of 48, 96, 144 or 192 zones to suit the customer’s needs,” he says.

By simulating heat profiles, Athena is demonstrating key features on the expanded BEDROS line, including a new, user-friendly touchscreen interface that allows the operator to quickly set up and store the process. Molders can also establish communications with an external network via a new software package called Maestro Plus, making it simpler to monitor and control heat profiles.

“Previously, our customers would have to use multiple systems to control 192 zones, but now it is all in one package with one power connection and standard cabling from the back of the unit to the hot half of the mold. It is much easier to use, plus they are designed to be modular, so as needs change users can easily upgrade and expand the system to accommodate more zones,” Crawford says. The company also has its popular, compact, non-modular BEDROS multizone hot runner controller, which provides between eight and 32 zones of microprocessor-based temperature control, on display.

Athena Controls is also demonstrating its new Series RMX Modular Hot Runner Controller, which is a microprocessor-based, single-zone temperature controller specifically designed for runnerless molding applications. Fully self-tuning, and containing built-in diagnostics, RMX Series controllers feature LCD touchscreen display and CompuCycle routines that improve response time, reduce thermal fatigue and prolong heater life by applying AC power smoothly and continuously. Also, the new RMX features SafeChange “hot swap” that allows safe removal and replacement of modules, plus much more. As with the expanded BEDROS line, the RMX Series is equipped with Modbus communications software, as standard, to allow operators to collect data and control the system on-site or from a remote PC or smart device.

In addition to these standardized systems, Crawford says Athena is also capable of customizing systems to support customers’ requirements. “Based on the functionality desired, we work with our customers to deliver custom controller solutions that will help them achieve their process objectives,” he says.

Related Content

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's Additive Manufacturing Technology is Designed for Precision Tooling

-

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

-

Impacts of Auto’s Switch to Sustainability

Of all the trends you'll see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.