Automotive Plastics Adding More Value in Tough Times

The dramatic global downshifting in automotive manufacturing hasn’t put the brakes on plastics innovation, if recently announced developments are any indication.

The dramatic global downshifting in automotive manufacturing hasn’t put the brakes on plastics innovation, if recently announced developments are any indication. In fact, plastics’ value proposition has probably never stood out more clearly than in these difficult economic times. Struggling automakers have an even greater interest in exploring new materials and processes to deliver lower cost, lighter weight, and more easy recyclable parts and systems.

Take for example, Ford Motor Co., which launched its new Flex crossover utility vehicle with 11 new plastics applications, including many industry firsts. These and several other newsworthy advances in materials, processing, and creative product design were unveiled at the SPE Automotive Composites Conference in September and at the 38th Annual Innovation Awards, presented in November by the SPE Automotive Div. (This editor was a member of the panel of judges for the awards.) Among the new developments was a twin-sheet blow molding process for fuel tanks and a new technique to weld headliners. In materials, slush molded TPE, low-mass SMC, and a hybrid thermoplastic composite for horizontal body panels were introduced. Carbon fiber composites also staged a mass-production breakthrough.

NOVEL PROCESS FOR TANKS

An innovative twin-sheet blow molding process developed by Inergy Automotive Systems, Adrian, Mich., won both the Process/Assembly/Enabling Technologies category and the Grand Award. It eliminates post-mold operations and reportedly can meet the stringent California Partial Zero Emissions Vehicle (PZEV) requirements. It is used for the tank on the 2009 BMW 7 series sedan (not PZEV compliant) and has the same six-layer HDPE/EVOH construction as the standard blow molded tank.

The parison is split at the extruder head and an adapter diverts the material into two 8- to 10-mm-thick sheets, which are dropped between a central core and the mold halves. The core consists of three to 15 manually placed internal components such as rollover valves, fuel-delivery modules, and level sensors. Core actions attach the components during initial sheet forming and the empty core is withdrawn and the mold is closed to join and inflate the formed sheets. Overall cycle time is within ±5 sec of a typical blow molded tank, according to Dave Hill, Inergy research engineer.

The tank requires only one hole to insert the fuel delivery module. The process is claimed to provide greater control of wall thickness for weight savings. In addition, a PZEV-compliant tank is priced competitively versus a conventionally molded tank and is more economical than so-called PZEV “patch solutions,” according to Inergy. Another twin-sheet tank is expected to be commercialized in Europe early next year.

Another innovative blow molding application and winner of the Body Exterior category is the industry’s first integrated rocker molding and running board, which appears on the 2008 Ford Escape SUV. The rocker molding, step pad, and running board are combined in one piece blow molded of 15% glass-filled PP. It is attached to the body side, rather than the underbody, for improved fit and finish. The 1.75-meter-long side mounting, manufactured by ABC Group, Toronto, boasts a stiffness improvement of 56%, weight reduction of 8.6 lb, and a $5/vehicle saving in piece price and assembly cost.

A finalist in the Process/Assembly/Enabling Technologies category was Extol Inc.’s new InfraWeld infrared welding process, which replaces hot-melt glue in headliner assemblies. The first application is the headliner for the 2009 Ford F150 pickup, molded by TrimQuest, Grand Rapids, Mich. The compact welding head focuses infrared light, which melts and joins the plastic components. A flexible seal ensures no gap between the welded components and maximizes heat transfer. Pneumatic head pressure of 20 psi is said to ensure polymer mixing at the weld point and achieve a strong bond. Cool air is passed over the weld to remove heat. Using a fixture, multiple parts can be welded in 20 to 30 sec.

Elimination of hot-melt glue results in a 10% to 15 % weight reduction and 20% to 40% cycle time reduction on the F150 headliner. The InfraWeld process also reduces squeak and rattle and enhances recyclability. Extol has proven the process in other applications including door panels, carpet systems, trunk storage, and package trays. Another Ford vehicle is expected to use InfraWeld in a headliner next summer.

NEW FRONT-END HYBRID

A novel plastic-metal hybrid technique using hydroformed metal tubes won its first commercial use as a structural front end on the 2008 Ford Falcon and was a finalist in the Chassis/Hardware category. In development for at least four years, the new HydroPlast Structures system was developed by SABIC Innovative Plastics and Vari-Form Inc., Troy, Mich. Pressure-sequenced hydroforming of sheet metal creates a tubular closed section that doesn’t require overmolded plastic ribbing, unlike previous open-section hybrids. The metal tube is overmolded with 30% glass-filled Noryl GTX PPO/nylon from SABIC, and a 3D attachment or SmartLok connection is created between the tube and plastic. The result is said to be more efficient use of both steel and plastic.

Key features include a 20% weight savings over competitive stamped-steel hybrids, reduced packaging space, increased airflow to the radiator, and a cross-car dimensional tolerance of ±1 mm. Other applications such as instrument panels are being explored.

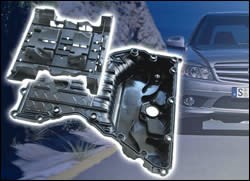

Winner of the Chassis/Hardware category was the first thermoplastic oil-pan module for a passenger vehicle. It integrates an upper shell of die-cast aluminum and a multifunctional lower shell that is injection molded of DuPont’s 35% glass-filled Zytel 70G35 HSLR nylon 66. This oil pan for the Daimler C-Class diesel sedan is 2.4 lb lighter than all-aluminum designs. In addition, the heat-stabilized nylon’s long flow distance and short injection time cuts cost by 20% to 25%. It offers high stiffness and hot-oil resistance up to 150 C/302 F. An integrated oil baffle improves flow and reduces sloshing. An integrated windage tray/oil deflector is welded onto the flat section of the pan. DuPont envisions other integrated features including the oil pick-up pipe, oil level switch, oil filter, and other oil return components.

MATERIAL INNOVATIONS

The winner in the Materials category is a new slush-molded TPE for instrument panel skins, said to be the first in North America. The styrenic/olefin blend was developed by interior-components supplier Inteva Products, Troy, Mich. It reportedly performs as well as or better than PVC or TPU at 20% lower weight and without VOC emissions or fogging. It is used on IP skins for the 2008 GM Saab 9-7X SUV.

The material is a drop-in replacement for TPU and PVC and can be processed on the same powder slush-molding equipment. The formulation’s low melt viscosity at low shear is comparable to PVC, and a unique additive provides excellent powder packing and high flow, resulting in no clumping and reduced porosity. Other key features include low-temperature ductility to -35 C and better long-term weathering and dimensional performance than PVC. Inteva has issued an exclusive license to compounder A. Schulman Inc. to manufacture and sell the material as part of its Invision TPE line in the U.S. and Europe.

A finalist in the Materials category uses nanoclays in a new low-mass SMC, said to be the first to achieve low density without using hollow microspheres. It trims weight by 20% in a compression molded truck hood assembly for Navistar International. The hood is based on Arotran 720 polyester for the Class A surface panel and Arotran 740 polyester for the structural reinforcement. Both resins come from Ashland Composite Polymers.

About 200 phr of calcium carbonate filler is replaced with 20 to 50 phr of a reinforcing filler and 3 to 5 phr of Cloisite nanoclays from Southern Clay Products, according to Helena Twardowska, Ashland senior staff scientist. The nanoparticles offer highly efficient dispersion and facilitate microvoiding with less use of low-profile additives, according to Twardowska. They also provide reduced shrinkage, 15% to 20% greater modulus at high temperatures, and improved surface appearance.

The SMC formulation includes acrylic tougheners to improve paint performance. Mechanical properties are maintained despite the lower density, and existing processing equipment is used. The material costs about 15% more than standard SMC. Ashland has several other low-mass SMC programs under way in deck lids and other transportation applications.

A finalist in the Exterior category was an acrylic pillar appliqué for the industry’s first invisible touchpad keyless entry system on the Ford Flex and Lincoln MKS. Altuglas International developed an improved Plexiglas acrylic taillight material that boasts greater impact and scratch resistance than previous grades. A new colorant package was also developed to impart a deep jet black color. The resin was chosen over standard high-gloss options such as hard-coated PC, prepainted aluminum, and powder-coated steel. The new material saved $2.50 per appliqué. The two-shot molded appliqué consists of the new modified black acrylic and a 2-mm-thick, semi-transparent keyless entry window made of medium-impact acrylic.

A finalist in the Body Interior category was a new proprietary TPO developed by Ford and custom compounder Advanced Composites. It reportedly sets a new standard for low-temperature toughness in seamless passenger airbag systems for hard IPs. The new TPO on the Ford Focus and Lincoln MKS is ductile at -40 C and meets Ford’s stringent cold-temperature impact requirements. The airbag system, injection molded by Automotive Components Holdings, Saline, Mich., is less costly and 5 lb lighter than comparable soft IP versions.

The winner of the Body Interior category exemplified creative product design in a modular floor console and shifter assembly for the Ford Flex. The injection molded structure uses 20% glass-filled recycled SMA to support a floor-based shifter, eliminating the use of metal brackets and hardware previously used to secure the shifter to the floor pan. The integrated system simplifies online assembly, improves fit and finish, and optimizes packaging. Cost is reduced and weight is 5 lb less than earlier designs.

NEW BODY PANEL SOLUTION

At the SPE Automotive Composites conference, SABIC and Azdel Inc. jointly launched Ixis 157, a hybrid thermoplastic composite for horizontal body panels. The sandwich structure consists of a 50% random glass-reinforced PP core with two 0°/90° skins of 60% continuous unidirectional fiber-reinforced PP. The skin facilitates a Class A paint finish and maintains dimensional stability while the core aids in processing and reduces overall material cost. The skin is calendered onto the core to produce semi-consolidated sheet, which is typically consolidated into 2-mm-thick parts, according to Mike Birrell, Azdel’s director of exterior composites.

The composite is 50% lighter than steel and reportedly offers excellent sound deadening. It has an HDT of 157 C/315 F and is designed for off-line painting.

Since the material is designed for low-pressure molding (15 to 100 psi), aluminum tools can be used, resulting in an 85% cost savings versus steel body panels in volumes up to 100,000 parts. The material can be compression molded in 2-min cycles, and low-volume parts can be consolidated in 20 min with vacuum bagging at 200 C/392 F.

There are no commercial applications to date, although the material has been showcased on concept vehicles such as GM’s Chevrolet Volt and the Hyundai QarmaQ. A roof application is expected to be commercialized next year in the U.S. and Europe. Under development is another hybrid composite called Ixis 200, which is based on SABIC’s Xenoy PC/PBT. It features an HDT of 200 C and is designed for online painting and e-coat priming.

CARBON FIBERS STAND OUT

Carbon-fiber composites made their biggest splash yet in automotive. The Performance and Customization award went to the Class A hood assembly for the 2009 Corvette ZR1, said to be a first for a mass-produced vehicle that meets FMVSS frontal crash tests. The carbon-fiber/epoxy prepreg part has a flexural modulus of 14 million psi and weighs about 12 lb, or about half as much as the SMC hood it replaced. The two-piece structure consists of a six-layer unidirectional Class A outer panel that is painted and an exposed dual-weave prepreg inner panel that is polished to a near-Class-A surface. Also an industry first is the see-through polycarbonate window with a special PUR coating to minimize scratches, fogging, and corrosion. It is bonded to the hood with a specially developed adhesive from Ashland Chemical.

The hood is vacuum bagged and autoclave molded by Plasan Carbon Composites, Bennington, Vt. A low-VOC, fast-cure epoxy from ETS, has a built-in UV stabilizer. Plasan cures eight parts in less than 60 min at 290 F. Plasan also uses robotic bonding, machining, and auditing systems. Tooling costs under $100,000, about 90% less than molds for SMC. Final part cost is competitive with SMC, according to Plasan engineering manager Gary Lownsdale. Another carbon-fiber hood has been commercialized for the Ford Mustang Shelby 500KR.

RENEWABLE TECHNOLOGIES

The winner of the Environmental category is described as the first use of a soy-based polyol for PUR foam seating. Approximately 12% of the petroleum-derived polyol is replaced with the soy-based version in PUR foam seating for the 2008 Ford Mustang and eight other Ford models.

Development partner Lear Corp., Southfield, Mich., purchases the soy-based polyols from Urethane Soy Systems Co. and blends them in a proprietary process with conventional polyols. The blended formulation releases 66% fewer VOCs and exhibits less fogging than traditional oil-based polyols, according to Ash Galbreath, Lear’s director of advanced materials and comfort engineering.

For the future, Lear and Ford aim to increase the soy-based polyol content to 25%. Meanwhile, Ford has licensed the technology to John Deere Co., Moline, Ill., and is pursuing other interior foam applications, including headrests, arm rests, and center consoles.

Another finalist in the Environmental category is said to be the first use of recycled TPO in a weatherable appearance part. The air inlet panel on the GMC Envoy and Chevrolet Trailblazer SUV is injection molded of 100% post-consumer recycled TPO derived from damaged auto fascia. The formulation contains about 20% talc.

Recycler MRC Polymers has a proprietary paint-removal process that yields recycled material with minimal contamination, a common challenge with recycled TPO. Physical properties are said to be equivalent to those of virgin resin for this non-painted part. The waste that is produced from the water-based recycling process is dried and sold as filler. Cost savings of 2.2% were achieved vs. virgin resin and 445,000 lb of landfill-bound material was salvaged.

IN-MOLD DECORATING

A finalist in the Process/Assembly/Enabling Technologies category was the chrome-appearance front grille for the Hyundai Verna, claimed to represent the first use of more than four decorative film inserts injection molded simultaneously into one partially decorated part. Six thermoformed inserts, made of 0.5-mm-thick ABS with a Soliant chrome-appearance paint film, are molded onto an ASA core in a single shot. This eliminates post-mold chrome plating, masking, and painting and improves recyclability and part durability.

Soliant and molder Motost of Korea developed special tooling to handle multiple inserts with one central gate instead of sequential gating. This was accomplished by creating diverters on the core and cavity sides to gain maximum control of resin flow.

FIRST EPP HEADREST

A finalist in the Safety category was the first use of steam-chest molded expandable PP foam in head-restraint inserts that meet FMVSS-202a static requirements for a headrest. These are found on several Ford models, including the Focus, Flex, MKS, and F-150 truck. JSP International produces and sells the bead and Tegrant Corp. molds the parts for Windsor Machine Group. Local depressions are molded into the foam core to reduce permanent set during FMVSS-202 backset and height-retention testing. The snap-fit part design is formed without slides or lifters, providing a secure fit to the head-restraint rod and ease of assembly. The part’s unique geometry allows for 32 cavities to be molded simultaneously. Tooling costs are significantly less than injection molded or blow molded headrest cores.

Wire-cut PS foam for low-cost head-impact energy absorption was the winner of the Safety award. Dow’s Impaxx PS foam sheet is extruded into blocks and then wire cut into complex shapes for the Ford Focus. Key features include no tooling, 25% weight reduction vs. competitive products, and design and validation within five days.

Related Content

10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreSustainability Among the Many Niches at Niche Polymer

Founded in 1987, Niche Polymer continues to grow—both organically and through acquisition—by focusing its product-development efforts on ever-changing market needs. Adding value to both industrial and post-consumer scrap is a growing part of this effort.

Read MoreConfiguring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreRead Next

Material and Process Developments Highlight SPE Automotive Awards

Custom backlighting with color-converting plastics and robotic extrusion of door seals won two categories of the 37th Innovation Awards presented in November by the SPE Automotive Div.

Read MoreLong-Glass Thermoplastics and Blow Molding Grab SPE Automotive Awards

Long-glass reinforcements and structural blow molding accounted for four of this year’s nine SPE Automotive Innovation Awards, presented last month in Detroit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More