Blow a Bottle with Liquid Instead of Air

New technology--to be made widely available--blows and fills bottles in the same step.

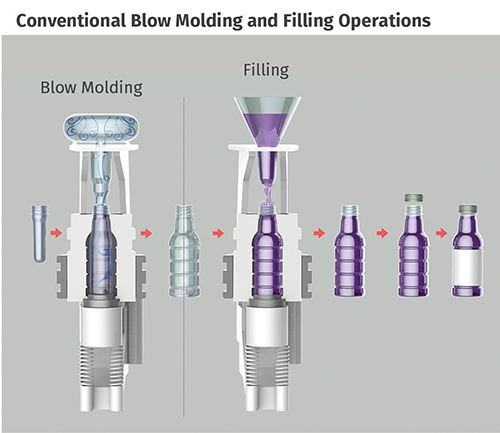

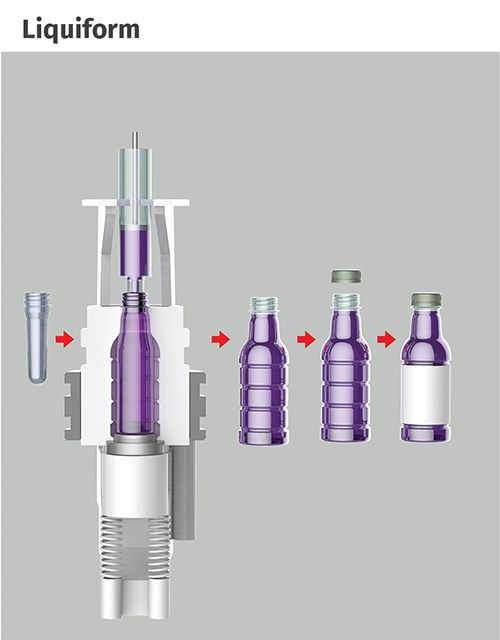

Last week, global packaging supplier Amcor and French blow molding machinery producer Sidel announced a “game-changing” advance in efficiency of packaging beverages, liquid foods, and home and personal-care products by combining bottle forming and filling into one step. They are actively seeking partners to help commercialize their technology for reheat stretch-blow molding bottles using the liquid contents instead of compressed air to expand injection molded preforms inside molds. This approach is said to offer enormous savings by eliminating the energy cost of compressed air and the hardware and operating costs for two separate machines for blowing and filling. It also eliminates storing, transporting, and handling empty bottles with attendant risks of damage or contamination. According to David Feber, v.p. of R&D for Amcor Rigid Plastics, Ann Arbor, Mich., over 90% of current stretch-blow machines are already linked to filling and capping units in so-called “Combi” systems.

Called LiquiForm, the new technology is being made available by LiquiForm Group, the business development arm of the DISCMA joint venture of Amcor and Sidel, formed in 2012. Said Ann O’Hara, president of LiquiForm, “We seek to make the technology widely available through a licensing and royalty system. We want it to become a standard.” This means that the technology is available to other bottle makers besides Amcor and to other machine builders besides Sidel (U.S. office in Norcross, Ga.). Equipment makers and consumer-goods companies will be offered LiquiForm “developer kits” in the next 12 months. LiquiForm already has signed an agreement with Yoshino Kogyosho, Japan’s largest plastic bottle maker, to further develop the technology. Full-scale commercialization of which is expected by 2018.

Amcor filed for the first of many patents (over 250 at present) on the LiquiForm concept back in 2006, and some patents on related ideas—that were never practiced in the real world—date back decades. Among other firms that pursued R&D on similar approaches is Nestle Waters, one of the world’s leading bottled water companies, which has agreed to sell its “highly complimentary” patent portfolio to LiquiForm. Although aimed initially at PET (both hot and cold fill), LiquiForm technology works at least as well with PP and PE, says O’Hara. Four LiquiForm demonstration systems are in use for licensees and development partners at development centers in Ann Arbor and Octeville, France.

LiquiForm eliminates compressed air, which eats up around 70% of the total energy used in stretch-blow molding. Overall manufacturing costs are expected to be reduced 25% compared with current blowing and filling systems. Optimized bottle designs and lightweighting are said to be possible because blowing the bottle with an incompressible liquid instead of a compressible gas provides greater control. Feber says LiquiForm throughput rates are the same as for PET bottle blowing today, but much faster than current filling rates. Ancillary equipment for capping, handling, and labeling would have to be modified to take advantage

of potentially greater overall output rates. LiquiForm will consult with partners and licensees on changes to preform and mold designs and material formulations specific to this process.

Related Content

-

Use Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

-

50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

-

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

.png;maxWidth=970;quality=90)