Blow Molding (K 2001 Preview)

One cluster of blow molding innovations on display at K 2001 will address the need for more versatile single-stage injection stretch-blow molding (ISBM) machines. A thirst for energy savings underlies plans to launch all-electric units for PET and HDPE containers. Also in the limelight are advances in large-part technical blow molding.

A player returns to ISBM

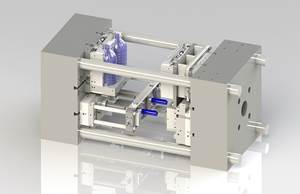

One major initiative at K 2001 is the return after several years of Husky Injection Molding Systems Ltd. to the stretch-blow machinery market. The Bolton, Ont., company—a top supplier of preform injection equipment—plans to launch a complete one-stage ISBM system aimed at customers who require a cost-competitive system for short-run custom and wide-mouth containers. Husky views this as one of the most dynamic, high-growth sectors in PET containers today. The Husky Index Stretch Blow (ISB) system will be displayed at the show, but the commercial launch is set for early 2002.

Husky’s system locks in a 2:1 ratio between the injection and blow molding cycle (versus 4:1 or 5:1 for current single-stage equipment). The relatively long residence time in the blow mold is expected to yield high-quality bottles and lend itself to heat-setting operations. Output of the system is rated at a maximum 6000 bottles/hr. It permits tool change in 2 hr versus the industry standard of 8 hr, resulting in favorable economics for lower-volume applications.

Another ground-breaking system for PET bottles is the NSB 100 unit from Automa of Italy and Maple Grove, Ill. It is termed the first all-electric system to embody the “one-and-a-half-stage” approach in a one-stage ISBM system. Company officials explain that a longer transition period occurs between injection and blow molding, during which the preform is partially cooled, resulting in improved bottle quality. The unit is designed with a 5:1 injection/blowing ratio and is offered in 5:1, 10:2, 15:3, and 20:4 combinations of cavities. All-electric operation is said to reduce cycle times, yield 60% energy savings, increase precision, and reduce overall cost. Automa says the system is especially well suited to lower-volume runs and odd-shaped bottles.

Nissei ASB Machine Co. in Japan and Atlanta is launching the ASB-70DDPW for high-speed production of up to 55-g PET bottles. Described as a one-stage, double-row configuration, the unit offers 7000 bottles/hr capacity and has a small (18 x 6.6 ft) footprint.

Appearing for the first time outside of Japan is the HSO-4, a four-cavity version of Nissei’s two-stage, double-blow, reheat stretch-blow line. HSO Series units are intended for making containers able to withstand up to 188 F filling temperatures. The double-blowing feature increases crystallinity and reduces stresses in the bottles.

Krones AG in Germany and Franklin, Wis., plans to show a system for in-line coating of PET bottles with glass (silicon oxide) to achieve barrier and extended shelf life for packaging beer. The BestPet Plus bottle is made by physical vapor deposition of SiOx on the bottle exterior between blowing and filling steps at a rate of 20,000 bottles/hr.

Larger injection-blow

In injection-blow molding, Novapax Kunststofftechnik of Germany and Hammonton, N.J., will introduce several larger versions of its four-station machine at the show. The firm’s initial model NSB 400/250 has 44 tons of injection and 27.5 tons of blowing clamp force. Extending that line are the NSB 650/400 (71.5 and 44 tons, respectively), NSB 850/500 (93.5 and 55 tons), and NSB 1250/650 (137.5 and 71.5 tons). All units have a Siemens S7 closed-loop controller.

Electric units for extrusion blow

SIG Blowtec of Germany and North Branch, N.J., will show the largest all-electric extrusion blow molder yet released. The Blowpac 4/4-100D has 18-ton clamp force and a 4 x 100 mm centerline dimension. It reportedly provides 33% higher productivity than the largest existing Blowpac machine when running standard 32-oz containers. SIG says the machine’s 20-40% energy savings justify a decision to phase out production of its equivalent hydraulic version of this machine.

New from Automa is the AT15D extrusion blow unit for HDPE jerry cans and bottles of up to 20-liter size. It can also run handled one-liter chemical bottles. Its new carriage design uses linear bearings instead of the previous columns with bushings.

Jomar Corp., Pleasantville, N.J., is introducing a larger hydraulic-powered extrusion blow machine, the EBM 25. This single-station machine can be configured in two ways: For those who mold large parts or up to 25-liter containers, a version is offered with one to four parisons and an optional accumulator head. For cosmetic and pharmaceutical bottles, Jomar’s other configuration equips the unit with five to 12 parisons and provides faster cycles. In both versions, a tiebarless platen aids fast and easy mold changes. In-machine trimming with a gripper to orient bottles is also provided.

Bekum America in Williamston, Mich., plans to demonstrate integration of its advanced in-mold labeling system with the high-output BM-905D double-station, long-stroke unit for handled one-liter HDPE bottles. New features include label-magazine replenishment without any interruption of production and a placer arm that improves label placement.

Plastimac SpA of Italy (distributed by American Jet Stream, East Brunswick, N.J.) is adding a new Plastiblow unit designed for containers of up to 30 liters. The PB30/S has a clamp force of 30 tons and utilizes roller plates on horizontal overlapping linear guides to move the platens. They increase precision of movement and dramatically reduce friction and wear, according to Plastimac. The unit’s efficiency is reflected in relatively small size of the hydraulic tank (150 liters) and motor (5.5 kw).

For production of soft-touch coextruded bottles, Plastimac is also introducing the PB500/D, a double-carriage unit with a 50-mm extruder for the inner HDPE layer and smaller extruder for the exterior soft TPE material.

Industrial parts

Graham Machinery Group, York, Pa., will introduce the C-30 reciprocating-screw extrusion unit for 5-gal polycarbonate handled water bottles. A new 24:1 L/D plasticating unit and flow-through die head are said to limit degradation and facilitate cleaning. Clamp speed has been increased for faster cycling. The C-30 offers bottom blow with compression for a compacted neck finish. Trimming and deflashing are done in-line and containers exit in upright, oriented position.

For the U.S. market, SIG Plastics recently added a smaller version of its accumulator-head system for large technical parts. The Blowtec CP-90 offers many of the same features as its CP-120, CP-240, and CP-360 models, including radial wall-thickness programming, and ability to handle fiber-reinforced materials. The new unit comes in single- and dual-head versions, and features shot sizes of 5.8, 8.3, 13.3, and 20 lb.

Ossberger GmbH of Germany (represented here by FGH Systems, Denville, N.J.) has launched the Pressblower DSE 225 machine to meet requirements for larger, more precise under-hood parts for trucks, such as drive-shaft boots, rack-and-pinion boots, and shock-absorber covers. This larger model employs Ossberger’s unique combination of injection and extrusion blow molding. It has a new control system incorporating 100-point parison programming, as well as provisions for manipulating the parisons across more complex mold geometries.

Related Content

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreKrones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

Read MoreAll-Electric Machines & Blow Molding Automation Featured at K 2022

Magic MP spa will present new EBM auto adjustment, electric accumulator-head technology, a larger ISBM machine, a quick-mold-change system, and robotic product handling/palletizing at this month’s show in Düsseldorf.

Read MoreMold Opaque White PET Bottles – Without Pigment

Trexel and Husky are cooperating on molding recyclable opaque white preforms for PET bottles, which provide a light barrier using foam instead of pigment.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More