Coatings Give Aluminum Molds Cost/Performance Edge Over Steel

New cost-effective technologies are designed to make aluminum an attractive alternative to tool steels in a range of plastics molding processes. One method uses a plasma technique to convert the aluminum surface into a hard, dense, wear-resistant ceramic. Another approach uses electro-deposition to apply a surface coating with high hardness, corrosion resistance, and chemical resistance.

HARDER THAN STEEL

U.K.-based Keronite International Ltd. has developed a plasma electrolytic oxidation (PEO) process that raises the durability and release properties of aluminum to the level of steel. The chrome-free technology transforms the mold surface into an extremely hard crystalline ceramic oxide through anodic conversion under plasma discharge.

“This technology allows molders to use less expensive aluminum molds that have the same performance as tool steel,” asserts Philip Lund, Keronite’s European general manager. “It also extends the life of aluminum molds.”

Keronite creates a harder surface than steel or hard anodized aluminum and protects the mold from chemical attack when the plastic is heated. It also helps improve heat transfer and can be repeated if the tool requires alteration, machining, or welding.

Cost savings are said to be considerable when switching from steel to treated aluminum. For a tool to make a plastic part the size of a 3.9-in. cube, the Keronite treatment itself typically costs about 400 to 600 euros ($580 to $870 at current exchange rates). However, a switch from steel to aluminum reportedly saves 60,000 to 80,000 euros ($87,000 to $116,000) in total tool cost.

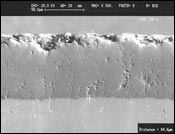

Typically, the aluminum mold is dipped into a patented, nontoxic electrolytic solution and then is connected to a source of alternating current. A plasma discharge is created on the aluminum surface, converting the metal surface into a layer of ceramic oxide 20 to 45 microns thick. The ceramic layer is said to “grow” into the surface of the aluminum in a uniform, controlled manner to form a defect-free interface with the metal. This outer layer therefore has better adhesion to the substrate than most deposited coatings such as plasma-sprayed ceramics.

As well as inward growth, the layer grows out from the original surface in a predictable manner. The extent of outward growth depends on the aluminum alloy and is typically between 10% and 40%. An accommodation for dimensional growth can be made in tool design or the layer can be polished back to the original surface dimensions. The layer also has a very fine pore structure that is said to be highly suitable for retention of lubricants—it can even be impregnated with PTFE to make a tough, non-stick, low-friction composite.

Depending on the aluminum alloy and thickness of the ceramic layer, surface hardness ranges from 500 HV to 2000 HV—well above the capability of hard anodizing. Aluminum can be rendered harder than steel, glass, and many silicon-containing compounds, according to Keronite. Research at the University of Cambridge, England, shows that the surface stiffness can be as low as 4.35 million psi, making it more strain-tolerant than most ceramic layers. Due to the excellent substrate adhesion and low stiffness, the ceramic layer shows good tolerance to differential thermal expansion and thermal cycling.

Another advantage is the lack of thinning in the coating on corners and edges of the mold. The coating follows the mold contours and can even be thicker on sharp corners, offering better edge protection than rival processes. Untreated aluminum molds tend to wear along edges and in corners, where conventional dip-plating or painting processes produce thinner layers of protection due to surface tension (also known as “dog-bone” effects). Hard anodizing also offers limited protection to edges or sharp corners because its columnar growth results in wedge-shaped cracks on tight radii, creating points of weakness.

HANDLES INJECTION MOLDING

The Keronite PEO system can be used in low-pressure processes such as blow molding and thermoforming and in high-pressure processes such as injection molding. In blow molding and thermoforming, the surface layer can take a textured finish. Where a smooth but durable surface is required, the ceramic layer can be polished with conventional means or by wet blasting.

For injection molding, the PEO treatment is used together with PTFE to provide a quick-release finish. Best results are obtained with water-based PTFE emulsions or thin solvent-based solutions, which penetrate the hardened layer to produce a long-wearing PTFE/ceramic composite. The PTFE-impregnated surface can be polished to the required smoothness.

The technology has won early adoption in Europe, although several prototype molds are under development in the U.S. The most rapid penetration has occurred in Denmark, where the coating is used for thermoforming molds for margarine tubs. Other emerging applications include injection molded food packaging and caps and closures and blow molded PET bottles for water and carbonated soft drinks.

Keronite has 14 licensees and three joint ventures in Europe and Asia, and an OEM licensee in the U.S. The company also operates its own service centers in the U.K. and Indianapolis. These firms work directly with moldmakers and molders.

TITANIUM OXIDE COATING

Meanwhile, another new coating technology for aluminum molds is based on an electrodeposition process. The Alodine EC2 ElectroCeramic Coating from Henkel Corp. consists of titanium oxide that is applied anodically with a specialized rectifier. The 5- to 10-micron-thick ceramic coating reportedly increases surface hardness, corrosion resistance, and chemical resistance. It has a hardness of 800 Vickers plus 10 times higher corrosion resistance than standard aluminum coatings, and a low coefficient of friction of 0.2.

The coating is targeted for a range of molding processes. There are no commercial applications yet, although several development projects are under way. It is available in the U.S. through licensed vendors.

Related Content

How to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.png;maxWidth=300;quality=90)