Cobot Supplier Universal Robots Doubles U.S. Staffing, Adds three Offices

The North American business of the Danish collaborative robot—cobot—manufacturer to open offices in Michigan, Texas and California.

To support burgeoning growth in the U.S. market, Universal Robots A/S, Odense, Denmark (U.S. headquarters in East Setauket, N.Y.) is in the process of opening three offices in Ann Arbor, Mich.; Irvine, Calif.; and Dallas Fort Worth, Tex.

Over the last four months, the company has doubled its staffing in the U.S. and is still hiring, according to Craig Tomita, Western Region area sales manager, Universal Robots USA Inc., who spoke with Plastics Technology at the Pacific Design & Manufacturing event (Feb. 9-11, Anaheim Convention Center).

Tomita said the lease for the Irvine facility was signed only two weeks prior to the Anaheim event, adding tat all these new offices will include a classroom space for training customers on the Universal Robot (UR) technology (read more about cobots in Plastics Technology’s February feature). Over the last five years, company sales have doubled every year, according to Tomita, who estimated that there are around 1500 URs installed in the U.S. since it began selling here in 2012.

Globally the company—which was founded in 2005 and sold its first systems in 2009—claims a cobot market share of 60 to 75%. Last June, Universal Robots was acquired by testing and industrial automation supplier Teradyne Inc., North Reading, Mass., for an undisclosed amount. In a release announcing the purchase, Teradyne described the cobot market as a $100 million segment of the overall industrial robotics sector that’s growing at more than 50%/year. At the time, Teradyne said UR had shipped more than 4000 systems worldwide.

North American Show Debut

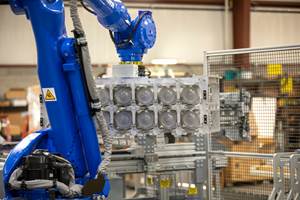

At the show in Anaheim, the company displayed three systems in operation: UR3, UR5 and UR10 robots. The number in each name designates the respective robot’s payload in kilograms. Tomita said that at this point, machine tending is one of the most common applications, particularly in machine shops where the robot opens the door to a machining center, removes finished parts and then adds in new blanks. He added that customers are continuously finding new tasks for the UR technology.

In addition to continuous operation, Tomita said an additional benefit of the UR is agility. “No guarding means mobility,” Tomita said. “We can move them from machine to machine—the robots are designed to be flexible automation, not hard. You don’t get the full benefits of automation when you have to use caging.” Supporting this is the single-cable power source, which allows the system to run off 110V AC power, and the lightweight design (the largest version, the UR 10, weighs in at just under 64 lb).

Tomita says another key selling point for the UR is ease of programming. Complicated programming has served as a barrier to entry for some small- to medium-sized shops to adopting more complex automation systems, according to Tomita, but he believes UR systems remove that barrier.

In “free-drive” mode, workers can move the UR arm through the motions they require, entering in position No. 1, 2, 3 etc. as they go. They can also set “no-fly” zones where the robot cannot enter or utilize area scanners that will slow down the robot as workers approach. As a true cobot, if the UR comes in contact with a person, or anything it’s not supposed to, it stops moving immediately, using advanced controls to know exactly where it is in space at all times.

These systems have been particularly suited for custom manufacturers operating in a low-volume high-mix market, where substantial investments in automation that’s not flexible are problematic due to the constantly changing mix of work. Tomita noted that by swapping out the end effector attached to the UR arm—water jet cutting, drill, laser, adhesive dispenser, etc.—you can change the task the robot takes on.

Working With People, Not Replacing Them

Tomita stressed that the UR systems take on what is best handled by a robot: repetitive tasks that require precision and can become tedious and/or dangerous to people, while leaving human workers to do what they do best: apply logic and use fine motor skills.

“We’re marketing these as another tool in the tool box,” Tomita said. “You use these amongst people not instead of people. Ultimately workers love these because they’re empowering.” To that point, Tomita noted that affinity is reflected by the fact that workers tend to name the robots over time. Initially referring to a unit as “him” or “her” over the first month of a deployment before giving the robots a formal name after two months of operation.

Related Content

An Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreDrones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

Read MoreAutomation Evolution: From Robots to Work Cells, Solo Devices to Integrated Systems

Injection molding automation has progressed from devices to systems, from simplicity to more complex capabilities. The author traces this development through various levels of automation – all still available choices today – and analyzes the costs and capabilities for each level.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreRead Next

ROBOTS TO ‘COBOTS’: Next-Gen Automation in Plastics Processing

So-called ‘collaborative robots’ are a new category of ‘human-friendly’ automation that can work safely side by side with people, unprotected by guarding.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More