Colloidal Silica Cuts Cycle Times in Molding Engineering Plastics

A year ago, we reported research showing that very small amounts of ultra-fine silica can reduce injection molding cycle times 20% to 30% in PP, nylons, PBT, and ABS (see Learn More). These results have since been confirmed in numerous commercial applications, according to Dr.

A year ago, we reported research showing that very small amounts of ultra-fine silica can reduce injection molding cycle times 20% to 30% in PP, nylons, PBT, and ABS (see Learn More). These results have since been confirmed in numerous commercial applications, according to Dr. Pravin L. Shah, head of Rheo-Plast Associates, a technical consulting firm that has been working on application development and laboratory testing of Nan-O-Sil ASD colloidal synthetic silica for its manufacturer, Energy Strategy Associates. According to Dr. Shah, the cycle-time reductions have been demonstrated in 16- and 32-cavity molds, along with other benefits such as reduced flow lines and improved dimensional stability. In addition, Nan-O-Sil ASD reportedly can improve color dispersion, allowing some molders to reduce colorant levels and thereby pay for the silica.

New laboratory test results from Rheo-Plast indicate that the benefits previously demonstrated also extend to other engineering resins such as acetal, glass-filled polycarbonate, PPS, and PEEK. Also new is the ability of Energy Strategy Associates to supply Nan-O-Sil ASD in compounded pellet concentrates with a wax or a desired resin as the carrier. Up to now, the colloidal silica has been supplied as a white powder with spherical particles of 0.02 to 0.55 microns (20 to 550 nanometers).

As shown in the accompanying table, addition of just 0.8% silica shortened injection molding cycle times for tensile test bars by 22% to 31% for unfilled acetal copolymer, PPS, and PEEK, as well as 33% glass-filled PC. Mechanical properties were generally maintained or improved. Although the data are not shown, Rheo-Plast also found that Nan-O-Sil ASD reduced cycle times by 5% with Noryl PS/PPO blend and 27% with HDPE. Dr. Shah also notes that the silica eliminated sticking problems that commonly occur with PPS.

It is believed that colloidal silica reduces cycle time by speeding cooling, even though the amount of additive is very small. The companies are working with the School of Polymer Processing and Materials Science at Penn State University in Erie, Pa., to study thermal effects inside the mold and arrive at a better understanding of how colloidal silica works to shorten molding cycles.

Dr. Shah says the cost savings possible from faster cycles outweigh the additive cost, which is less than 3¢ per pound of resin at the 0.8% addition level. That works out to less than $3/lb for the pure colloidal silica.

In addition to the new pellet concentrates, there are different ways to add Nan-O-Sil ASD in pure powder form at the processing machine. One is to tumble blend the additive with resin for 15 min before molding. According to Dr. Shah, there is no dusting because the silica tends to stick to the pellets. He adds that there is no safety hazard in handling Nan-O-Sil ASD powder.

Another method is to use a feeder at the machine throat to meter the silica in proportion to the resin. In addition, users of liquid colors or additives can mix the silica with the liquid prior to molding.

Effect of Nanosil ASD on Properties of Engineering Plastics | |||||||

| Material | Cycle-Time Reduction, % | Tens. Str., kpsi | Elong. @ Yield, % | Flex. Mod., psi | Notched Izod Impact, ft-lb.in. | HDT @ 66 psi, F | MFI, g/10 min |

| Acetal | |||||||

| 8500 | 6 | 360,000 | 1.2 | 310 | 9 | |

| 23 | 9400 | 6.5 | 380,000 | 1.2 | 310 | 9 |

| PC + 33% Glass | |||||||

| 18,300 | 3.3 | 1,020,000 | 2 | 305 | 7 | |

| 29 | 19,000 | 3 | 1,020,000 | 2 | 305 | 7 |

| PPS | |||||||

| 12,500 | 1 | 610,000 | 0.5 | 400 | 10 | |

| 31 | 13,400 | 1 | 650,000 | 0.5 | 400 | 10 |

| PEEK | |||||||

| 14,500 | 5.1 | 600,000 | 1.6 | 320 | 17 | |

| 22 | 15,500 | 6 | 700,000 | 1.6 | 320 | 17 |

Related Content

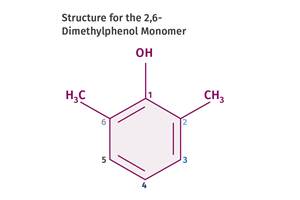

Tracing the History of Polymeric Materials: Polyphenylene Oxide

Behind the scenes of the discovery of PPO.

Read MorePrices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MoreScaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More