Commodity Resin Prices End Year on Downward Path

Falling feedstock costs are one factor driving prices lower for PP, PS, PVC and PET, while PE remains flat.

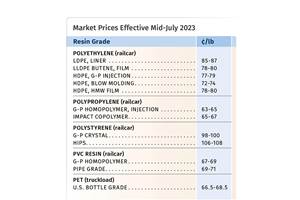

As we approach the end of the year, prices for four of the five large-volume commodity resins are heading downward. Among the key drivers are lower-cost feedstocks—in the case of PP, approaching double-digit levels—as well as slowed demand, year-end destocking, and some competition from lower-cost imports. Prices of PE, though also impacted by some of these factors, plus slower export activity, were expected to remain flat despite two looming price hikes.

These were the views last month of purchasing consultants from Resin Technology, Inc. (RTi), Fort Worth, Texas; senior editors from Houston-based PetroChemWire (PCW); and CEO Michael Greenberg of the Plastics Exchange in Chicago.

PE PRICES FLAT

Polyethylene prices remained flat in October and November, after the September 3¢/lb price hike. Suppliers delayed their October 3¢/lb increase to November, and their November 3¢ increase to December. Mike Burns, RTi’s v.p. of PE markets, ventured that prices would remain flat this month as well, but that could change early next year. “Eight out of the last 10 years, we saw PE prices move up in the first quarter due to strong exports and domestic restocking. For this coming year, it’s not clear what will happen with exports. But domestic demand is likely to continue strong, so I don’t expect PE prices to go down.”

In fact, Burns saw domestic demand as the key driver for the next round of price increases. He did not expect feedstocks and inventory levels to be the short-term price drivers; both ethane and spot ethylene prices were lower last month. In early November, the cost to produce ethylene was near 17¢/lb, and the cost to make a PE pellet was 33¢/lb, down 5¢/lb from the end of September. He saw strong resin demand in North America as affected by tariffs: “All low-cost commodity-grade finished goods—from a broad range of bags to shrink wrap—are no longer being imported from China. Major distributors of these products have turned to domestic film processors.”

Weighing in, PCW senior editor David Barry noted that there was no momentum to support domestic price increases, and he highlighted flat exports as one key issue. He said suppliers would need to decrease export prices and that they were initiating discussions to ramp up exports before the end of the year. There were also reports of slowed domestic demand, particularly in film sectors, as a result of destocking in the aftermath of hurricane season, forecasts of lower prices before year’s end, and year-end inventory management.

The Plastics Exchange’s Greenberg reported a very strong October for the spot PE market, with plenty of low-cost offers in LLDPE and LDPE film grades and HDPE injection grades. Going into November, he saw spot PE prices moving up 1-3¢/lb, helping to reduce the large gap (about 10¢/lb) between spot and contract pricing. Greenberg noted that export demand was also starting to sag as a result of sharply lower crude oil prices. “If oil continues to fall, and bearish sentiment accelerates worldwide, export demand and pricing could soften and generate another wave of lower-priced offers.”

PP PRICES FLAT TO SIGNIFICANTLY LOWER

Polypropylene prices remained flat in October, in step with propylene monomer contracts, but the potential for as much as a double-digit drop emerged in early November. “It was a surprise that prices did not drop as spot monomer prices were unwinding—down about 12¢/lb from end of September to end of October,” said Scott Newell, RTi’s v.p. of PP markets. Meanwhile, what appeared to be margin increases of 2-3¢/lb were issued by Braskem for Nov. 1 and by LyondellBasell for Dec. 1, with no apparent support from other suppliers.

Both Newell and PCW’s Barry expected that November monomer contracts would settle 8-12¢ lower, with PP prices dropping in kind. Said Barry, “I think it would be a bit of a stretch for suppliers to expect to get a margin increase.” These sources also noted that monomer availability was trending upward, as both PDH (on-purpose propylene) units were running more smoothly and there was a bit of a shift at the cracker level toward propylene. Moreover, PP demand appeared to be down since September, with competitive PP imports growing.

By the first week in November, the Plastics Exchange’s Greenberg reported that spot PP trading had slowed as buyers were looking at plummeting feedstock costs and either walked away from the market or purchased lower volumes. He also cited improved availability of both homopolymer and copolymer, with spot prices dropping by as much as 3¢/lb. Added Newell, “We’re seeing more than a 3¢/lb spot-market decrease. This might prove beneficial for processors in their 2019 contract renegotiations. We’ll close the year with much lower pricing, which is the best defense against demand destruction.” These three sources characterized the PP market as still somewhat tight to relatively well-balanced.

PS PRICES TRENDING DOWN

Polystyrene prices rolled over in October, following the previous month’s 2¢/lb price hike. While November prices had yet to be determined, one supplier had signaled that prices would remain flat. “This was a surprise to the industry, as most people expected that 2¢/lb gained in September would be given back,” said Robin Chesshier, RTi’s v.p. of PE, PS and nylon 6 markets. Both she and PCW’s Barry cited the falling prices of all PS feedstocks—both domestic and global—as well as slower seasonal demand.

Moreover, Chesshier noted that lower-priced PS import volumes this year were up 17-18% so far. “Buyers are pushing for lower prices and they have the right to do so,” she said, adding that this could open the door for a switch to imports as well as other plastics.

Noted Barry, “There’s definitely pressure from buyers to reduce prices in November based on feedstock costs alone. Even if suppliers keep prices flat, they will have a very difficult time keeping prices flat in December; a substantial price drop in benzene contracts is expected, as evidenced by spot benzene prices.” He added that the rule of thumb is that every 10¢/gal benzene price move translates to 1¢/lb for PS prices. Both sources noted that spot benzene prices had dropped nearly 50¢/gal between September and early November, while early settlement of October ethylene contract prices dropped by 2.5¢/lb.

PVC PRICES FLAT-TO-DOWN

PVC prices rolled over in October and were likely to be flat to lower through the remainder of the year. This is despite the 2¢/lb October price hike that’s still on the table, according to both Mark Kallman, RTi’s v.p. of PVC and engineering resin markets, and PCW senior editor Donna Todd. Their reasoning: Market fundamentals do not support an increase—i.e., falling feedstock prices, lower resin export prices, and seasonally slower demand.

PCW’s Todd reported that PVC suppliers had aimed to get their 2¢ increase in October and then keep prices flat through year’s end. But an industry pundit projected failure of the October price hike and prices remaining flat or dropping by 1¢/lb in November: “Once a whiff of a possible price decrease was proposed, resin buyers leapt at it and were considering a penny price drop in November to be a fait accompli.”

Kallman noted that as 2019 resin contract negotiations were taking place, processors would aim for lower prices based on lower fourth-quarter ethylene and resin export prices, along with slowed domestic and export demand since September. “The trade war with China will continue to impact PVC finished-goods imports. To a certain degree, domestic demand could be advantageously impacted.” He characterized supply/demand is balanced despite planned maintenance outages in fourth quarter.

PET PRICES DROP

Prices of domestic bottle-grade PET began to fall in early fourth quarter, driven by a drop in seasonal demand along with bloated supply of imports, according to PCW senior editor Xavier Cronin. Offgrade PET ended October at 72 ¢/lb delivered to the U.S. South in truckload and bulk truckload (48,000 lb) quantities, down 2-3 ¢/lb from the start of the month. Prime PET for non-contract truckload/bulk-truck business dropped by 3-4 ¢/lb to the high 70 ¢ range for both domestic and imported resin (FOB U.S. South and Midwest).

Prices in November were expected to fall another 2-3 ¢/lb due to the typical seasonal slowdown in demand after the high-consumption summer season for PET bottles (water, carbonated beverages and other warm-weather drinks). At the same time, a glut of PET imports is making a buyer’s market. December PET prices were expected to fall on the order of 1-3 ¢/lb by most estimates, while the holiday season kicks into gear and many PET-sector plants see a reduction in production, according to Cronin.

Meanwhile, in October the U.S. International Trade Commission determined that the domestic PET industry had not been "materially injured or threatened with material injury" by PET imports from Brazil, Indonesia, South Korea, Pakistan, and Taiwan; so no antidumping duties are to be imposed on imports from these five countries, which accounted for about 50% of all domestic PET imports in 2017. Also, the preliminary duties that had been collected this year as the ITC investigation proceeded—in the form of cash deposits posted with U.S. Customs and Border Enforcement—will be reimbursed.

Related Content

Nexkemia Acquires Polystyrene Recycling Assets

The polystyrene manufacturer finalized its purchase of Eco-Captation, a recycler.

Read MoreCommodity Resin Prices Flat to Lower

Major price correction looms for PP, and lower prices are projected for PE, PS, PVC and PET.

Read MorePS Prices Plunge, Others Appear to Be Bottoming Out

PS prices to see significant drop, with some potential for a modest downward path for others.

Read MoreFirst Quarter Looks Mostly Flat for Resin Prices

Temporary upward blips don't indicate any sustained movement in the near term.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More