Composites Show Features Cost-Saving, Low-HAP Materials

Making high-strength composites less expensively was the dominant theme of the recent Composites 2003 Show in Anaheim, Calif., sponsored by the American Composites Manufacturers Association (formerly the Composites Fabricators Association). Among the stars of the show were the vacuum infusion process (VIP), along with a number of new resins—including several non-traditional material chemistries—and new initiators. (New reinforcements, fillers, additives, and equipment will be covered in future articles.)The closed-mold VIP method is attracting a growing following from spray-up fabricators who want to meet the EPA’s MACT (Maximum Achievable Control Technology) standards for hazardous air-pollutant (HAP) emissions, which take effect in 2006.

Making high-strength composites less expensively was the dominant theme of the recent Composites 2003 Show in Anaheim, Calif., sponsored by the American Composites Manufacturers Association (formerly the Composites Fabricators Association). Among the stars of the show were the vacuum infusion process (VIP), along with a number of new resins—including several non-traditional material chemistries—and new initiators. (New reinforcements, fillers, additives, and equipment will be covered in future articles.)

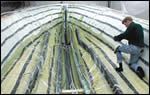

The closed-mold VIP method is attracting a growing following from spray-up fabricators who want to meet the EPA’s MACT (Maximum Achievable Control Technology) standards for hazardous air-pollutant (HAP) emissions, which take effect in 2006. HAP limits do not apply to closed-mold processes like RTM and VIP. The VIP process uses less resin and a lot less labor than spray-up, even though resins for VIP cost a little more.

One MACT requirement for open molding will be reduction of HAP content in resins—mainly styrene, but also the small amount of methyl methacrylate in some gel coats—to a maximum of 34%. Many resins and gel coats already meet this spec, as do most of the new products introduced at the show. And shortly after the show, CCP announced that all its gel coats will be MACT-compliant by Jan. 1, 2005. CCP will begin eliminating non-compliant products starting this April.

The VIP treatment

Reichhold and distributor Composites One both ran VIP demos at the show. Composites One also demonstrated its “light” RTM and “closed-cavity bag molding” (CCBM) processes. It offers a free video called “What Closed Molding Can Do For You,” covering all three processes.

Many of the companies involved in distributing resins and other supplies for VIP sponsored a new set of training DVDs about the process, which was introduced at the show by the discs’ producer, GRP Guru.com.

Airtech International, which offers a full range of VIP supplies, is now developing films, tubing, and flow media for what it describes as “the first high-temperature VIP system,” which will form epoxy parts in an autoclave (commonly used in aerospace prepreg molding) at temperatures as high as 300 to 400 F and pressures up to 100 psi. Most VIP molding is done at room temperature and pressure.

JHM Technologies, a supplier of RTM equipment, offers to license and teach companies to use “ZIP RTM,” a patent-pending variant of the RTM technique. It uses semi-rigid, skin-like, upper and lower composite molds, which JHM says licensees can easily make in a day. The process reportedly can be run by operators with entry-level skills.

Magnum Venus Products (MVP) introduced PrecisionTech RTM, a comprehensive program of RTM training, tool-design consultation, tool-building services, process consultation, and customization of equipment. Hardware includes preformers, mold-clamping systems, several types of injectors for RTM and “RTM Lite,” accessories, and PLC controls.

Vanishing reds & blues

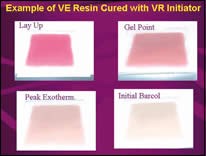

Two years ago, Akzo Nobel Polymer Chemicals started a trend when it began market testing its red peroxide initiator and cure indicator, trademarked Vanishing Red. The red indicator is integral to its newly commercial Cadox VR series of peroxides (MEKP, AAP, and CHP types)—not a separate additive.

Now, Crompton Corp. has introduced what’s believed to be the only “vanishing” blue peroxide on the market. Hi-point 90 Blue MEKP is for use in clear or white resins. Crompton also launched a new disappearing red cure version, Hi-Point 90 REDout.

Atofina Chemicals also showed new peroxide formulations. Luperox DHD-9L is a room-temperature-stable MEKP that is phthalate-free and low in hydrogen peroxide. It reduces porosity in vinyl esters. Also new is Luperox MC, a proprietary room-temperature-stable liquid that provides significantly shorter gel-to-cure times in SMC and BMC. At the same time, it yields gel times only a little shorter than with standard TBPB, so it reportedly can help solve problems of non-fills, pregels, and knit lines. Finally, Atofina came out with Luperox 223V75, a peroxydicarbonate offered as a lower cost alternative for pultrusion.

New resin technologies

Materia, an R&D firm, introduced a new catalysis system for inexpensive dicyclopentadiene cyclic olefin monomer. It cures liquid DCPD into a tough, clear thermoset polymer in one step, unlike other approaches that first make higher-viscosity prepolymers from DCPD. The difference is that DCPD’s water-like viscosity allows it to wet out high filler loadings—up to 89% by weight. DCPD also penetrates wood, creating impregnated baseball bats that carry a warranty against breakage.

Very large castings can be made in one pour. Cured resin reportedly has good chemical resistance, low shrinkage, and low moisture absorption. Neat resin has a density of 1.05 g/cc, HDT of 266 to 329 F, tensile strength of 7000 to 10,000 psi, flexural strength of 12,500 to 14,000 psi, compressive strength of 12,000 to 13,500 psi, elongation of 4% to 6%, flexural modulus of 300,000 to 350,000 psi, and notched Izod impact of 1 to 2 ft-lb/in. (Special formulations can achieve 11 ft-lb/in.)

Bayer Polymers is introducing to the U.S. technology already used in Europe for spraying up all-polyurethane spas and tubs that need no glass reinforcement or thermoformed acrylic shell. Almost all hand labor is eliminated through automated spraying of three-component Baytec RS water-based PUR into an open mold. This VOC-free process sprays a PUR sandwich of two solid skins around a cellular layer, about 0.75 in. thick overall. The exothermic cure takes only 15 min. Bayer is designing similar systems for marine and automotive applications, which are expected to be commercial in two or three years. Baytec RS can also be sprayed onto the back of formed acrylic or ABS without using any fiberglass. Roll-out is thereby eliminated, and cure time is much shorter.

Bayer also showed a GMC truck load floor for 2004 models made in closed molds with two sprayed PUR elastomer skins, two glass mats, and poured PUR foam. New Baytec SPR156D elastomer is used for the skins. Other Baytec SPR grades have been sprayed onto metal and concrete parts but not into molds as a skin material.

Also, Bayer delivered a technical paper explaining how to overcome the short gel times and void formation that have been hurdles to pultruding urethanes. Bayer found that proper selection of PUR polyols and isocyanates can avoid these problems and permit pultrusion of PUR at competitive speeds for products like railroad ties.

Rohm and Haas brought to the show new technology from its acquisition of the intellectual property of Master Works Ltd. in the U.K. Master Works M1 is a two-component aqueous system of acrylic polymer, gypsum, and other mineral fillers. The high-solids slurry sets in 15 to 20 min and can be sprayed, laminated, cast, and injected to create stone-like statuary, architectural decoration, solid surfacing, or molds.

The product was launched last summer in Europe. It is said to be nontoxic, low in odor, dimensionally stable, and non-combustible. It reportedly adheres to various substrates, is easy to clean up with water, and leaves no hazardous waste. Low exotherm permits thick castings. Rohm and Haas supplies color pastes and additives (thixotrope, diluent, cure accelerator, and retarder), as well as multi-axial reinforcing fabric and a high-shear mixing-blade attachment. Suitable spray equipment (1:1 ratio) is made by Sagola in Spain, which has a U.S. office. Rohm and Haas is also working with an Italian firm to develop spray equipment.

Reichhold launched a new family of urethane/polyester hybrids said to have epoxy-like performance. The first product, Dion Xtreme 31040, is a pultrusion resin designed for high levels of impact and shear strength plus smooth surfaces. It also offers medium-to-high reactivity, high resistance to heat and cyclic fatigue, and low viscosity.

Also new from Reichhold are two new resins for VIP. Hydrex 1-HF is an economical blend of polyester and vinyl ester with less than 35% HAP content. Already established in VIP, Reichhold’s Hydrex 100-HF is now available in a prepromoted version.

Reichhold also introduced Polylite ABR 33305, an acrylic bonding resin with 30% lower styrene content than conventional resins, ability to accept filler loading up to 60%, and good adhesion to thermoformed acrylic tubs, showers, spas, and sinks.

Dow Chemical introduced Derakane Poolmax vinyl ester resin especially for pools and spas. It is prepromoted for easy curing and thixotropic for sag resistance. It reportedly delivers good resistance to osmotic blistering. And unlike some competing vinyl esters, it is not made with maleic anhydride, so it has better hydrolysis resistance, Dow claims.

Dow also showed new pultrusion simulation modeling (PSM) software, offered through its technical support group to help customers reduce trial and error on new parts from several weeks to less than one week. It can be run on a laptop by a Dow technician at the processor’s plant and is said to predict processing variables within 10%.

Ashland introduced a conductive “B”-side polyester resin system compatible with most of its SMC “A”-side resin systems, including PhaseDelta 50425. A visible flocculate creates conductive paths through the SMC part. Parts molded with a loading of only 0.5 pph of the “B” resin can be painted electrostatically without use of a conductive primer, Ashland says.

AOC introduced Vicast A511-CCA polyester for cast products. This rigid, prepromoted orthophthalic is said to be colorless and water-clear.

The latest from Valspar is the Velocity series of metallic-effect gel coats that give a slick, shimmering look to personal water craft.

Related Content

Non-Fluorosurfactant Peroxide Curable Fluoroelastomers

Solvay launches new high-performance Tecnoflon FKM without use of PFAs used as process aids.

Read MorePartnership Develops TPEs with Reduced Carbon Footprint

Teknor Apex and Israel’s UBQ Materials have jointly developed new line of Teknor sustainable TPEs.

Read MoreGEON Performance Solutions Buys PolymaxTPE

Combined company aims to be global leader in thermoplastic elastomers.

Read MoreFoster Adds Specialty TPU and TPU Alloy Products to its Arsenal of Healthcare Materials

AdvanSource Biomaterials’ specialty TPU materials are used in application segments such as cardiology, orthopedics, drug delivery, endoscopy, wound care, urology, and neurology.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)