Composites Show Introduces Reinforcements, Fillers and Additives

Pultrusion, filament winding, SMC, BMC, polymer concrete, and advanced composites are targets for new reinforcing fibers, fabrics, fillers, and other additives introduced at the recent Composites 2003 Show in Anaheim, Calif.

Pultrusion, filament winding, SMC, BMC, polymer concrete, and advanced composites are targets for new reinforcing fibers, fabrics, fillers, and other additives introduced at the recent Composites 2003 Show in Anaheim, Calif. The show was sponsored by the American Composites Manufacturers Association. We reported on new resins and initiators at the show last month.

Reinforcements & fillers

Fibertech Co. Ltd., which spins metal fibers for industrial filters, is exploring use of its 50-micron metal fibers as reinforcements in epoxy for aerospace applications. The fibers are available in copper, stainless steel, chrome-nickel alloy, and titanium.

Crane & Co.’s Nonwovens Div. says it is the first to offer fluoropolymer surfacing veils for high-temperature and chemical-resistant applications. The new products include Cranemat FH, made from Solvay’s Halar ECTFE fluoropolymer. Cranemat FM is made of Solvay’s Hyflon MFA fluoropolymer and can withstand heat up to 600 F.

Crane also recently introduced PPS nonwoven surfacing veils for use in high-temperature electronics, underground storage tanks, and other structures. Cranemat PPS is thermally stable up to 400 F. Nonwovens can also combine PPS and mineral fibers.

Directional Fabrics is a new company supplying uni- and multi-directional reinforcements of carbon, aramid, and glass for military and other applications. It also offers multiaxial Kevlar sheets with up to seven unidirectional layers. Special coatings are said to improve durability of the unidirectional plies.

Saint-Gobain Technical Fabrics introduced MultiCore, a cold-preformable fabric for closed molding that consists of chopped-strand glass mat stitched on both sides of a polypropylene-fiber batting. It comes either 3 or 5 mm thick, and the ratio of glass to PP can be varied as needed.

Sister company Saint-Gobain Vetrotex has improved its RO99-673 glass roving with new sizing that’s said to yield better mechanical properties in pultruded profiles. The roving itself has enhanced compression resistance, which reduces damage during shipping, stacking, and handling, thereby resulting in more consistent payout.

Also, SGV has a new glass reinforcement that boasts superior acid and alkaline resistance over the full pH range, even at high temperatures. ARcotex glass was originally developed for concrete reinforcement, but new sizing technology makes it suitable for chemical tanks, pipes, and fittings.

Spheretex America introduced the first roving form of its lightweight Sphere.tex E-glass reinforcement, which is impregnated with hollow thermoplastic microballoons for added bulk. The spray up roving, called Sphere.strand Guncore, is 50% lighter than standard E-glass roving and is aimed at lightweight, stiff parts or sandwich construction. Sphere.tex also comes in aramid and carbon-fiber forms.

Advanced Glassfiber Yarns introduced heavier weights of two high-strength glass rovings. Its VeTron, reportedly the only high-performance glass compatible with vinyl esters and polyesters, now comes in a 206-yard/lb yield as compared with the initial 413 yield launched a year earlier. Made of high-silica glass, VeTron costs about $5/lb, or five times as much as E-glass.

Single-end, epoxy-compatible ZenTron glass roving is now available in a 225 yield as well as the original 675 yield. ZenTron costs $6 to $7/lb.

New from Plascore Inc. is a prototype reinforcing honeycomb made of Kevlar-coated paper. It will be more expensive than Nomex-coated paper (made with a different DuPont aramid) but also will have greater strength. It is expected to become commercial early this year.

Composites One offers Kit Concepts, a new service that provides customized kits of fiberglass mats and fabrics precut to specified sizes and nested in the order needed for lay-up. The service is aimed at both open and closed molding, including RTM and closed-cavity bag molding (CCBM).

Siscor (Spherical Industrial Solutions Corp.) will soon manufacture in North America porous glass spheres that it previously imported from Poraver in Germany. Although porous and lightweight (9.36 to 33.07 pcf, depending on size), this filler does not absorb water. Siscor will produce a new smaller bead size of 0.05 to 0.125 mm designed especially for thermosets. The smallest grade used to be 0.1 to 0.3 mm. Made from recycled bottle glass, the beads are used in Europe for concrete filler. Composites are a new market.

More new additives

Byk-Chemie USA showed a new thixotropic additive that prevents fillers from settling or floating. In closed-mold applications, Byk P9055 reportedly can keep glass spheres from floating or separating by building a “pseudo-plastic network” through hydrogen bonding. It is geared to pultrusion, SMC, and BMC—but not room-temperature curing because it deactivates cobalt accelerator.

Avecia showed off two new additives—Solplus D 530, which improves talc dispersion, and Solplus TX5, a new anti-settling agent. Avecia is also developing new Solplus deaerating agents for polyesters and epoxies.

Rexco’s Marbalease is a new fast-drying liquid wax mold release designed specifically for polymer concrete in metal or polyester molds.

Related Content

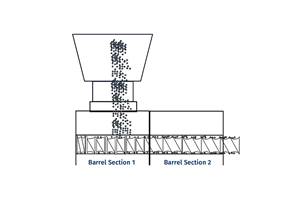

How to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreHow to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreSustainability Among the Many Niches at Niche Polymer

Founded in 1987, Niche Polymer continues to grow—both organically and through acquisition—by focusing its product-development efforts on ever-changing market needs. Adding value to both industrial and post-consumer scrap is a growing part of this effort.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More