Conair Applies Industry 4.0 to Make Service Smarter

Web-based and cloud-powered, Conair’s new Industry 4.0 SmartServices platform is key to its just-launched Uptime Guaranteed initiative.

Building off its new Uptime Guaranteed initiative, auxiliary equipment supplier Conair offered more details on SmartServices—the web-based industry 4.0 platform, which, paired with the company’s deep service technician pool, makes the ambitious performance guarantee on its equipment possible.

Speaking at the company’s pre-show press conference on Sunday, May 6, Conair President Larry Doyle said SmartServices harnesses the data already gathered by its equipment into a format that its customers can readily exploit.

“SmartServices is based on the fact that the controls of Conair equipment already gather a ton of data,” Doyle said. “Right now it resides only in the control.” Going forward, after the addition of compact wireless machine adapters (WMAs), described by Doyle as being the size of two decks of cards stacked on top of one another, the control panel can then transmit data up to the cloud, via the company’s own network.

“SmartServices is a cloud-based, web-based platform that is extracting data from our machine’s control and then posting that data out to the cloud and doing analytics on it,” Doyle said. “It is then repurposing the data into a dashboard that our customers can remotely access and monitor.” Once the system is analyzing process data, it can alert, alarm, and message the processor, as well as predict potential failures.

The program is launching with a no-cost, six-month trial promotion, where processors can try out SmartServices in their own facility with their own equipment. Conair stresses that the program’s web-based design means customers will never need to make hardware or software upgrades to have the latest version of the platform; it will be automatically upgraded on the web by Conair.

In operation, once the WMAs are installed and a connection is made, users can identify and configure their auxiliaries into the system, organizing them by equipment type, plant names, production lines, and physical locations. Once enabled, WMAs automatically collect data from each piece of auxiliary equipment and transmit it into the secure, cloud-based SmartServices database where it is processed and stored.

The SmartServices web portal then populates a dashboard with user data, creating a clickable list of user-specified equipment groups on one side and a large working screen on the other. Within the dashboard, users can dig into to Key Performance Indicators (KPIs) for each piece of equipment.

The KPI display shows real-time data, with three highlighted by default. Additional KPIs are shown in the form of real-time line graphs, and each one is color coded—red, yellow, or green—so users can quickly scan current operating conditions and performance trends. The Machine View display shows a schematic of the equipment overlaid with readouts of setpoint versus actual readings. On a dryer, for example, hopper inlet air temperature, temperature gradients within the hopper, outlet air temperature, dew-point setting, and target moisture level would be shown.

The Alarms screen displays real-time alarm status and history. A special panel allows managers to create an alarm hierarchy, and generate messages specific to each alarm type, with direct alarms sent to specific individuals or groups, depending on their type. Going further, Conair parts and service staff could be integrated into an alarm notification, enabling them to respond proactively.

Related Content

Film Processor Automates Complex Resin Management, Blending & Distribution System

Polipak of Poland moves to BlendSave system to support sustainability and Industry 4.0 objectives.

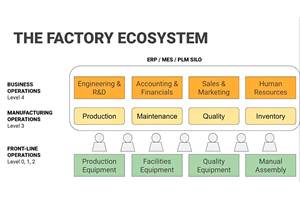

Read MoreWhat Comes After MES? It’s Already Here

If you’re not sure what the initials M-E-S mean, or whether that’s something your business needs, it may be time to look beyond MES to the next generation of manufacturing connectivity.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreHow Machine Monitoring Delivers Tangible Results

Much more has been said than done about reaping the benefits of data driven manufacturing among plastics processors. Good technology is essential, but change management is the most difficult part of the process. Here’s how to think about both.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)