Tooling: Critical Design Considerations for Sprue Bushings

Among them are good cooling, proper orientation, solid retention, structural integrity, generous radii, and an appropriately polished bore.

Last month I discussed how to reduce the massive area where the sprue, runner, and cold well intersect at the parting line. This month let’s take a look at some additional sprue-bushing design considerations to further improve the cycle time and to help avoid several processing problems.

Cooling: The sprue doesn’t need to completely solidify before opening the mold. It only needs to be able to shrink enough to negate the taper lock and have sufficient physical integrity to remain adjoined to the part or runner. But that doesn’t mean cooling the sprue bushing isn’t critical, because it is.

Do you have any molds that eject ice-cold parts, but the sprue is still as soft as butter? For maximum efficiency, parts should be ejected at, or slightly below, the material manufacturer’s recommended ejection temperature. That’s often a lot hotter than many molders eject at, and is an area for enormous savings potential. Putting a molded part against your forearm, or counting how many seconds you can hold it before it burns your fingers, is not the most accurate method of measuring the temperature of a molded part, which is one requirement for establishing the best cycle time.

A quick, effective way to improve the cooling of a sprue bushing is to replace the existing steel bushing with one made of a copper alloy.

Hand-held thermal-imaging cameras are excellent for checking part temperatures, and their prices have come way down over the past few years. Or you can buy an infrared temperature gun, which starts at about $20 and goes up to a couple hundred. These instruments are very good at indicating hot and cold spots, which is the result of either the part having uneven wall thickness, or the mold having uneven cooling. You might also be surprised to see how much the temperature of the part increases after ejection. That’s because the center of the part is still hot and the heat slowly dissipates to the surface.

A quick, effective way to improve the cooling of a sprue bushing is to replace the existing steel bushing with one made of a copper alloy. Note: When it comes to copper alloys, there is a trade-off between hardness and thermal conductivity. The softer copper alloys, around 17 Rockwell C, dissipate heat about seven times faster than carbon steel. The harder copper alloys, around 40 Rockwell C, dissipate heat about three times faster. I have used several types of copper alloys with great success over the years. However, regardless of some suppliers’ claims, my experience has been that copper alloys do not handle abrasive or corrosive materials nearly as well as tool steels do. A hard coating, such as diamond chrome, can greatly increase their longevity.

A sprue bushing, even one of a copper alloy, doesn’t dissipate heat into the air very fast—especially still air. Nothing does. That’s because air is an excellent insulator, or in other words, a lousy conductor. How lousy? The thermal conductivity of water is 0.35 Btu/hr-ft-oF. Air is 0.017, or 20 times less than water. Therefore, you should maximize the amount of contact area between the shank of the bushing and the bore in the mold. Additionally, preloading the length of the sprue bushing by about 0.0005 in. ensures good contact with the moving half of the mold. That is another metal-to-metal contact area that helps dissipate the heat where you need it the most. If the length of the sprue and the orifice size are relatively small, consider using a “U” Series or copper-alloy bushing with a 3⁄4-in. diam. shank, as opposed to the standard 1-in. diam. The rate of heat transfer is directly related to the distance between the hot and cold areas. A smaller-diameter bushing—shorter distance from the plastic to the cooling channels—means a faster rate of heat flow. Just make sure the wall thickness of the bushing at the parting line isn’t too thin.

Every designer considers the location of the water lines around the cavity and core, but all too often the cooling of the sprue bushing is an afterthought ... i.e., after you find out you’re not making the quoted cycle time. The same cooling guidelines you use for a cavity—such as the diameter of the water lines, their distance from the cavity wall, and their center-to-center distances—should also be applied to the sprue bushing. It’s best to put the water lines near the bushing on a separate circuit. This gives the molder more control of the process. For example, he may want 70 F water on the cavity, but needs 50 F on the bushing.

Some engineering grades of material require a very hot mold to get the proper flow. Keep in mind, you don’t heat the mold with oil. You heat the oil and cool the mold with it. Even if the oil is at 350 F, it’s still a lot colder than the plastic you’re trying to solidify. Therefore, oil

cooling lines near or around the sprue bushing for engineering-grade resins are equally as important as the water cooling lines in a mold for commodity resin grades.

One of the most efficient ways to cool a sprue bushing is with a cooling channel running directly around it. A single annular flow channel is usually sufficient, but if the bushing is long, two annular channels, or a spiral channel are more effective.

Some companies now offer sprue bushings with conformally cooled water channels. I haven’t used one of these bushings yet, but I have concerns about how to clean the water channel if it develops a debilitating layer of scale. There’s no doubt these conformally cooled bushings are far superior to solid-steel bushings, but I think a direct water-cooled, copper-alloy bushing will give them a run for their money.

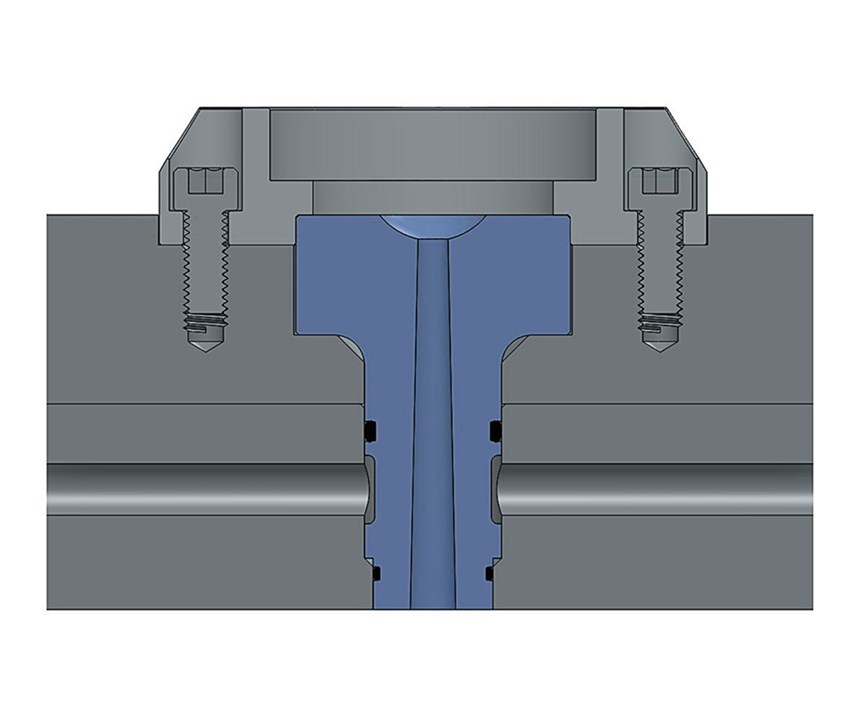

Retention: A sprue bushing usually needs to be keyed or oriented in a particular position in order to align a runner or part geometry machined into its front face. An inexpensive orientation method is to add a dowel pin through the head of the bushing. But dowel pins only orient bushings. They don’t retain them. Sprue bushings should be retained to prevent them from being “blown back” by injection pressure. Blow-back is caused by molten plastic pushing against the face of the bushing, like oil pushing against a piston in a hydraulic cylinder.

A common practice to retain a sprue bushing is to add one, or even two, 1⁄4-20 screws through its head. An alternative (some say better) method is to use a dowel pin and a “clamp-type” locating ring, such as DME # 6524 or # 6544, where a shoulder retains the perimeter of the bushing’s 2-in.-diam. head. (see my March 2017 column).

Surface Finish: The surface finish of the tapered bore in an off-the-shelf sprue bushing is usually well polished. If you are making your own sprue bushing, changing the size of an existing bushing, or repairing a damaged bushing, remember to polish it in “draw,” meaning the direction the sprue is removed. After stoning, it should be diamond polished, again in draw, to an SPI/SPE #B-2 finish or better.

There is an exception to this polishing rule. If the material is soft, as with PEs, flexible PVCs, polyurethanes, or elastomers, a vapor-honed or light sand-blast finish usually works better at releasing the sprue from the bushing. Copper alloys and lubricious platings and coatings also help overcome the adhesive tendencies of these “sticky” materials.

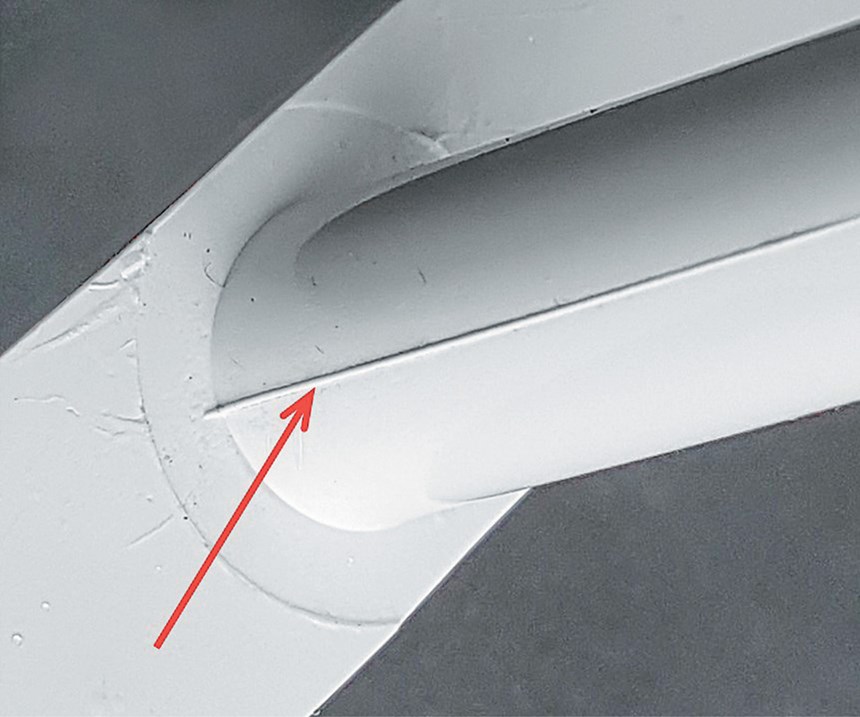

Sharp Edges: Everyone knows sharp inside corners are areas of high stress concentration. They are often the primary reason why a molded part or a mold component will crack. Sprue bush- ings are no exception. There are always sharp inside corners on a runner where it intersects the sprue, which can cause the runner to crack. Trapezoidal (not parabolic) runners machined into the face of a bushing often have sharp inside corners, which can cause the bushing to crack. Regardless of the runner type or what side it is machined into, be sure to add a generous radius to the orifice of the sprue bushing at the parting-line and on any geom- etry machined into its face.

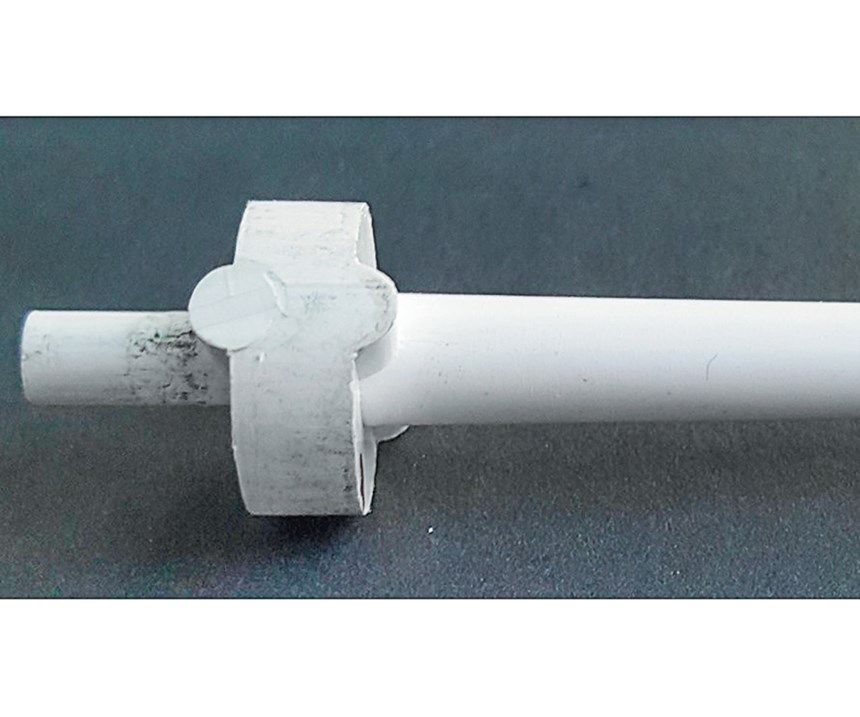

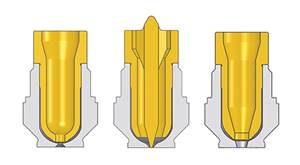

Structure: Who says the bore of a sprue bushing must be a smooth-sided, truncated cone? Almost 40 years ago, U.S. patent # 4,069,003 was granted to Ronald L. Cecchi and Louis Ramond for a sprue bushing with internal grooves. The grooves formed outwardly protruding ribs on the sprue, which solidify quickly. They improve the structural integrity of the sprue and its connection to the runner. They also prevent the sprue from rotating during extraction, which can be an important feature when it comes to sprue pickers and other automation. I have used these bushings before and they worked extremely well. But it’s been years since I have seen them for sale in any molding supply catalogs. Since this patent has expired, feel free to get creative with your wire or ram EDM machines.

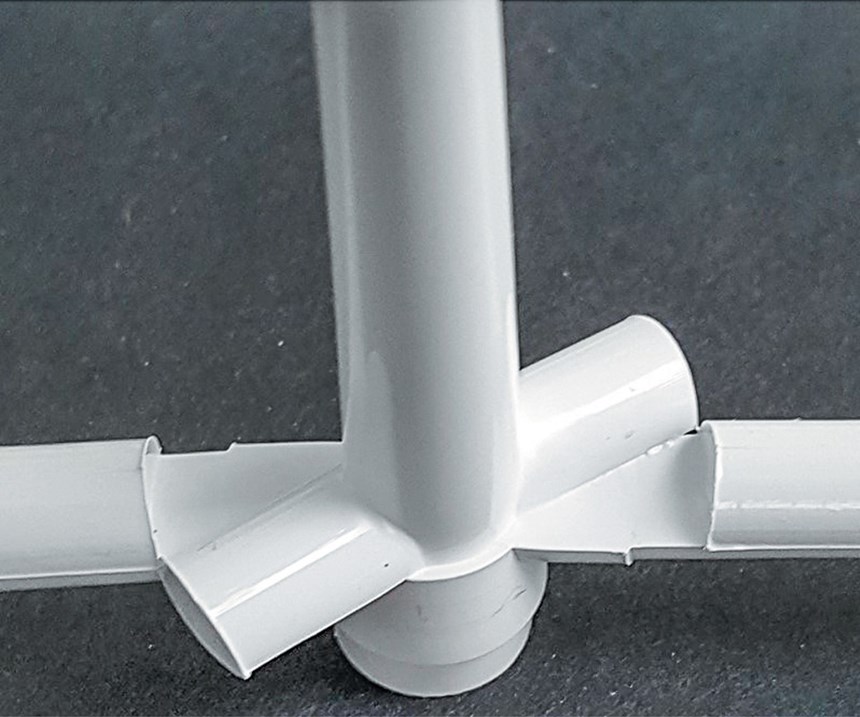

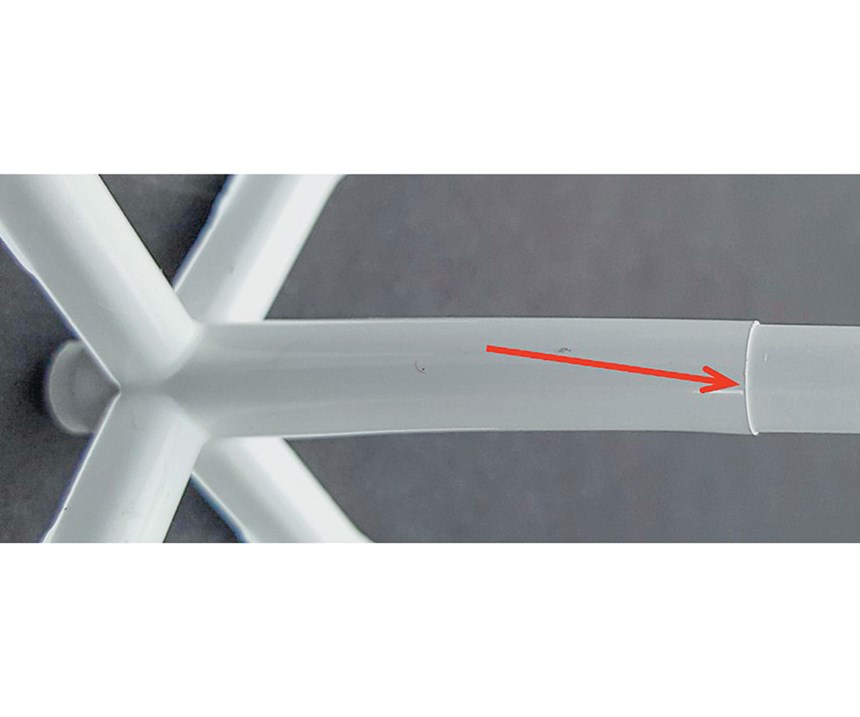

Like the design features of the Cecchi patent, adding gussets at the base of the sprue bushing helps keep a semi-solidified sprue attached to a runner.

Making Your Own: As noted in last month’s column, there are only four commercially available sprue-bushing orifice sizes (not including metric bushings), so many molds would benefit from a custom-made sprue bushing. You can use the best suited taper, orifice size, shank diameter, cooling method, material type and hardness. You can also incorporate many of the design features mentioned here.

Miscellaneous Considerations: Any transition, such as when a bushing ends but the sprue continues, must be stepped at least 0.005 in./side to prevent an undercut condition, which could cause the sprue to stick. This is common with MUD inserts.

The image above right is an example of someone really thinking outside the box. The sprue bushing in this single-cavity mold was mounted on a 15° angle. The angle offsets the location of the cavity closer to the centerline of the mold. In doing so, it reduces the uneven pres- sures which could cause the platens to tilt, and the mold base could be a little narrower to fit into a smaller machine.

Depending on the material type, cycle time and cooling rate, the sprue should be soft enough, yet structurally sound enough, to be withdrawn from the bushing. Looking at it from another perspective: this 15° angle is a lot shallower than a typical tunnel gate, which most of us use every day without any problems. It would have been better if that half-round runner wasn’t starving the sub-gate and if there was a radius at the parting line to help the material flow and ensure the sprue didn’t break off. But still, I like how this mold designer bucked tradition to build a better mold.

Careful consideration of the design of a sprue bushing, which includes the need for good cooling, proper orientation, solid retention, structural integrity, generous radii, and an appropriately polished bore, can turn a major headache into a smooth-running, profitable mold.

ABOUT THE AUTHOR: Jim Fattori is a third-generation injection molder with more than 40 years of molding experience. He is the founder of Injection Mold Consulting LLC, and is also a project engineer for a large, multi-plant molder in New Jersey. Contact jim@injectionmoldconsulting.com; injectionmoldconsulting.com.

Related Content

Hot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreRead Next

Tooling: Reducing the Mass In Sprue Bushings

Important and frequently overlooked details of sprue-bushing design can improve the process and profits for an injection mold.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More